Process and device for producing artificial boards by aid of spreading machine with multiple multilayer presses

A multi-layer press and paving machine technology, which is applied in applications, household components, household appliances, etc., can solve the problems of limited heat press power, increased investment and operating costs, long heat press cycle, etc., to increase production , saving investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

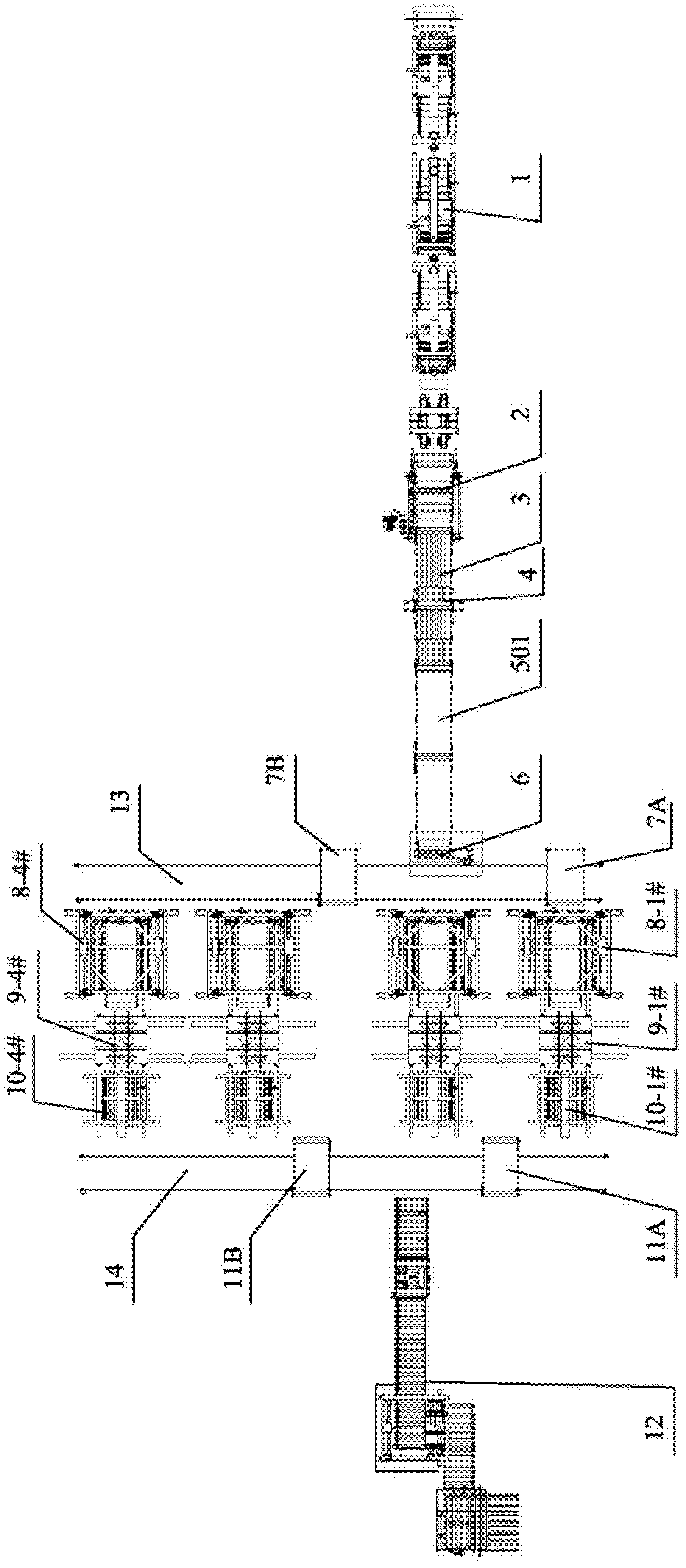

[0094] Embodiment 2: Except for the following content, other contents of this embodiment are the same as Embodiment 1.

[0095] After the four unloading machines 10-1#~10-4#, the separating conveyors 11A, 11B and the track 14 are arranged, and the track 14 is perpendicular to the fixed frame of the finishing line equipment 12. After the hot pressing is completed, the boards are unloaded by board unloaders 10-1# to 10-4#, and board conveyors 11A and 11B send the rough boards to the finishing line equipment 12 for sawing into finished boards.

Embodiment 3

[0096] Embodiment 3: Except for the following content, other contents of this embodiment are the same as Embodiment 1.

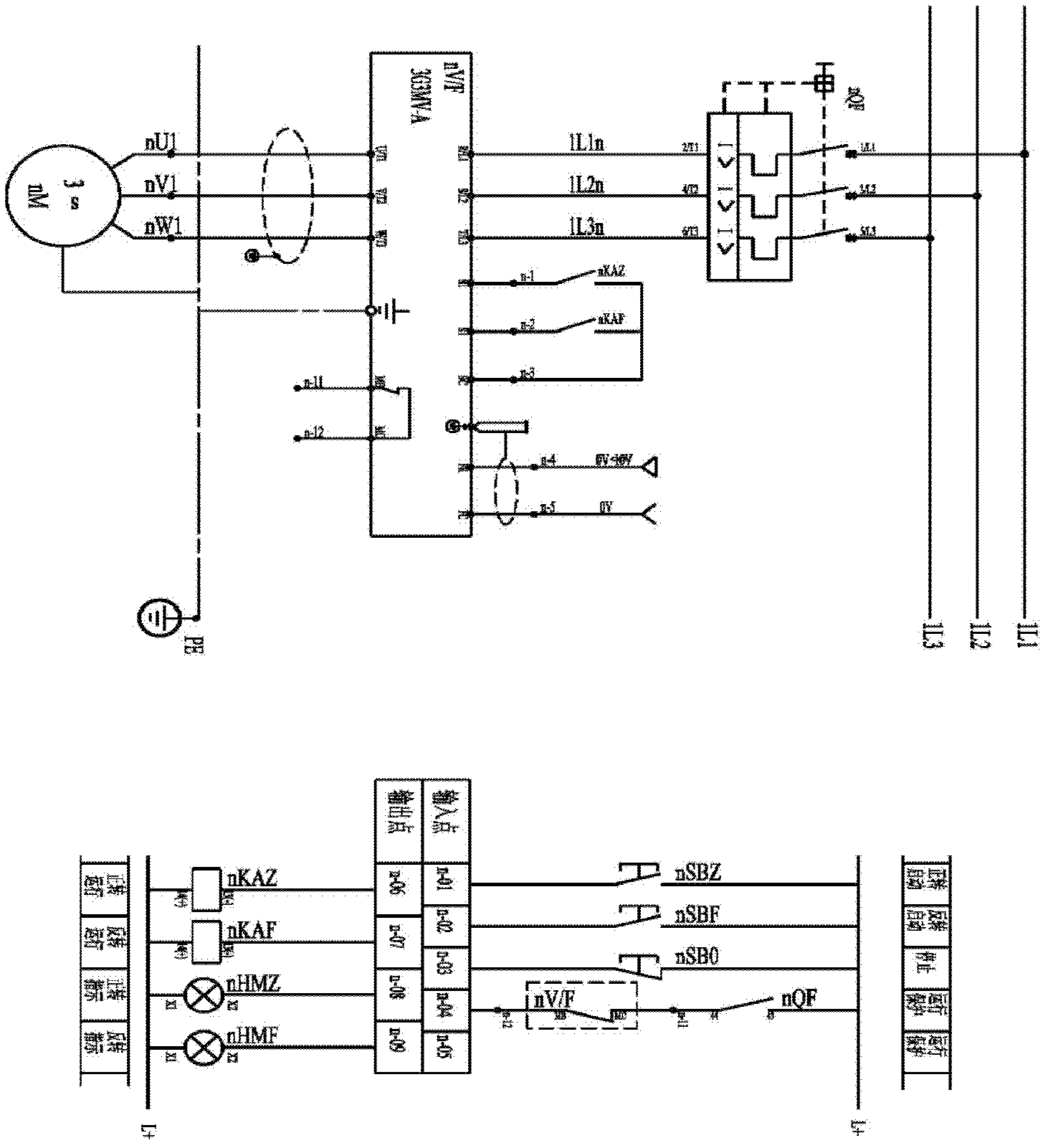

[0097] A low / high-speed wide-belt conveyor 502 is further installed between the low / high-speed wide-belt conveyor 501 and the high-speed wide-belt conveyor 6 to adjust the time interval at which slabs enter the high-speed wide-belt conveyor 6 .

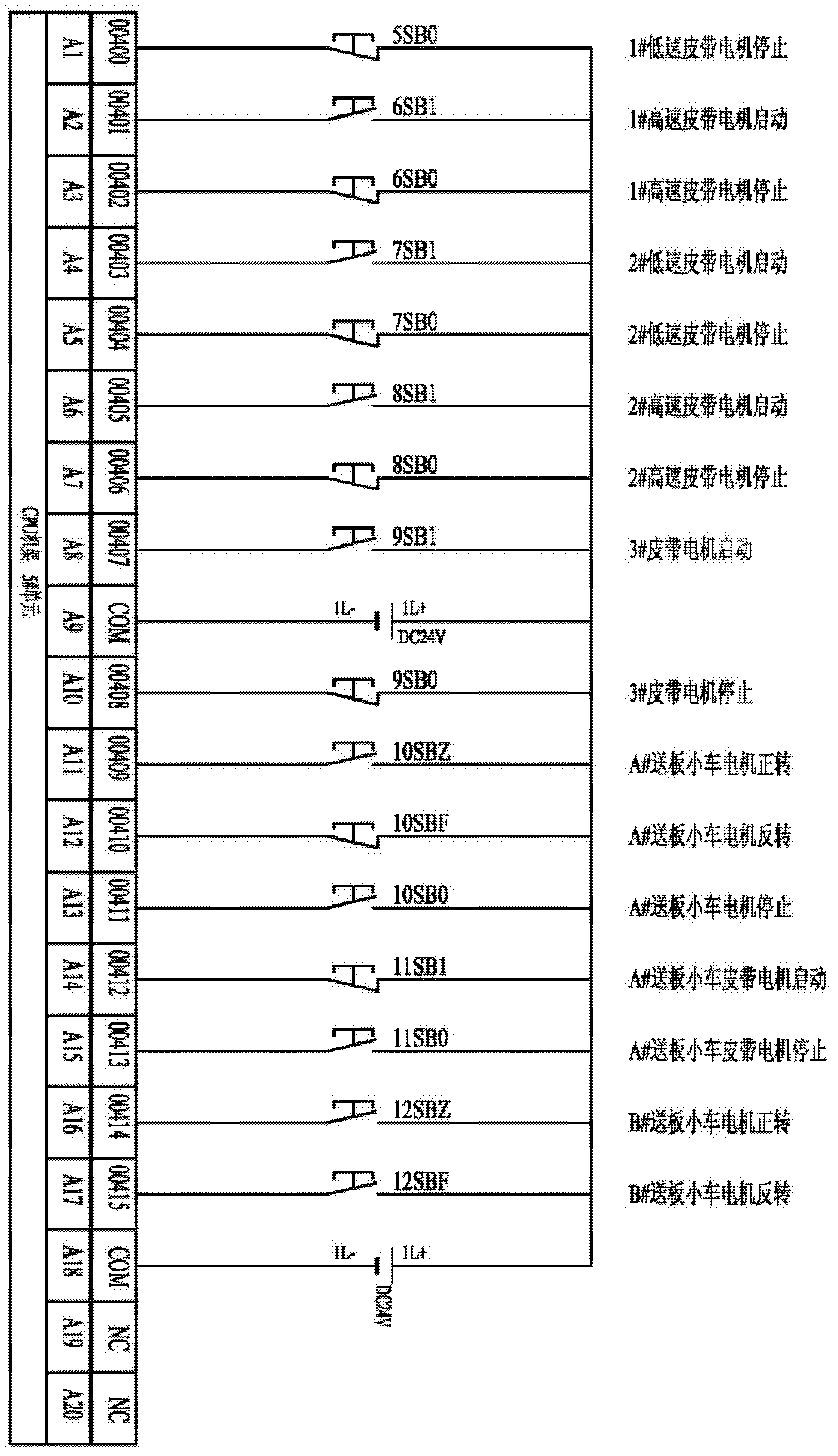

[0098] During work, when the pre-pressed slab cut off by the saw blade 4 of the cross-cut saw hits the photoelectric switch ISQ7 at the starting end of the running direction of the wide belt conveyor 501, the low-speed motors of the wide belt conveyors 501, 502 are disconnected, and the wide belt conveyors 501, 502 are started. , 6 high-speed motors. Afterwards, as the pre-pressed slab moves, the high-speed motors of the wide-belt conveyors 501, 502 are sequentially turned off, and the low-speed motors of the wide-belt conveyors 501, 502 are switched on sequentially. When the slab on the wide belt conveyor 6 hits t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com