U-shaped pipe mould device

A U-shaped tube and mold technology, which is applied in the field of U-shaped tube mold devices, can solve the problems of inability to install cooling channels in the mold core device, damage to U-shaped tubes, and high scrap rate, and achieve small core-pulling force, reliable performance, and high scrap rate. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

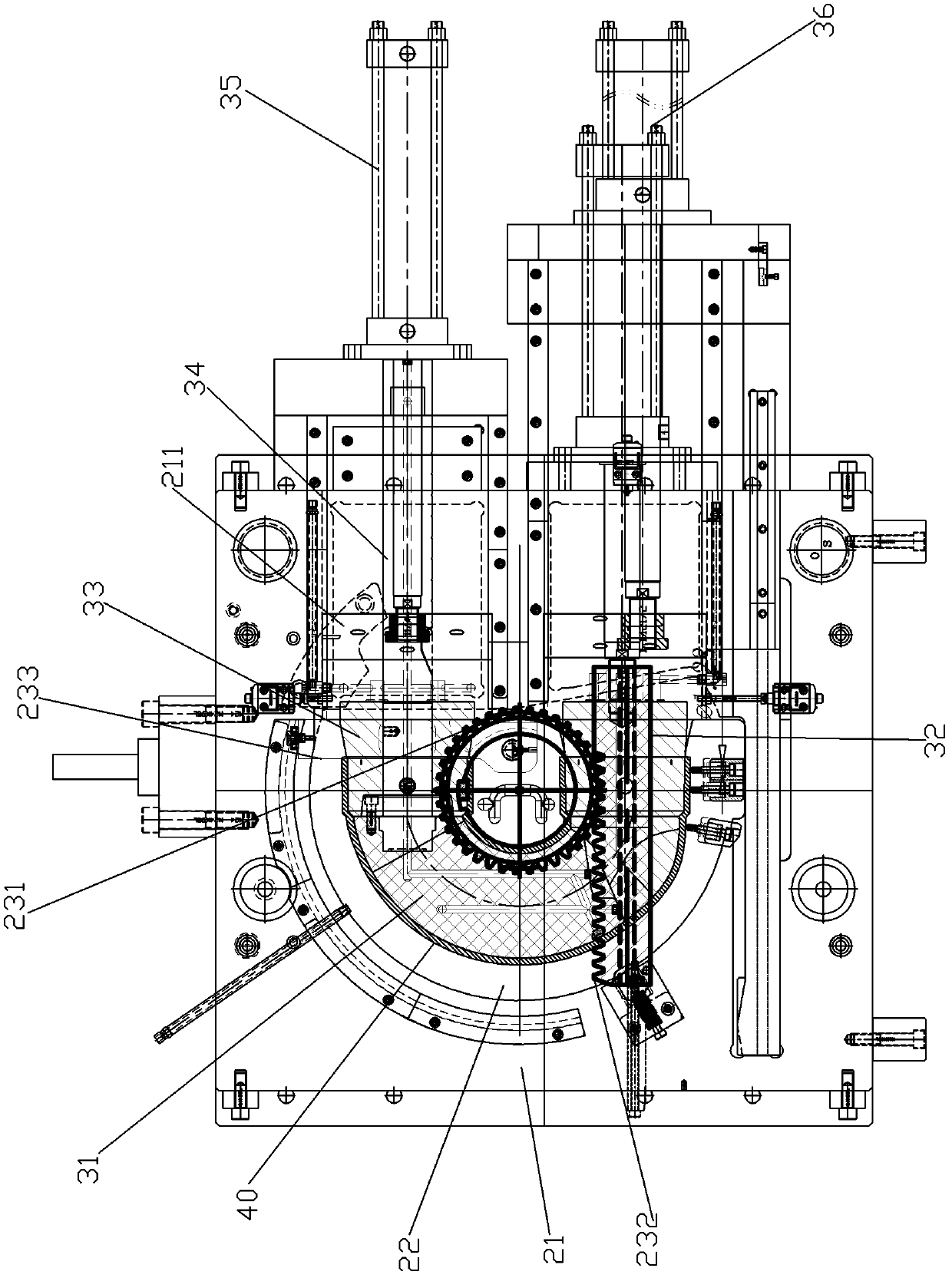

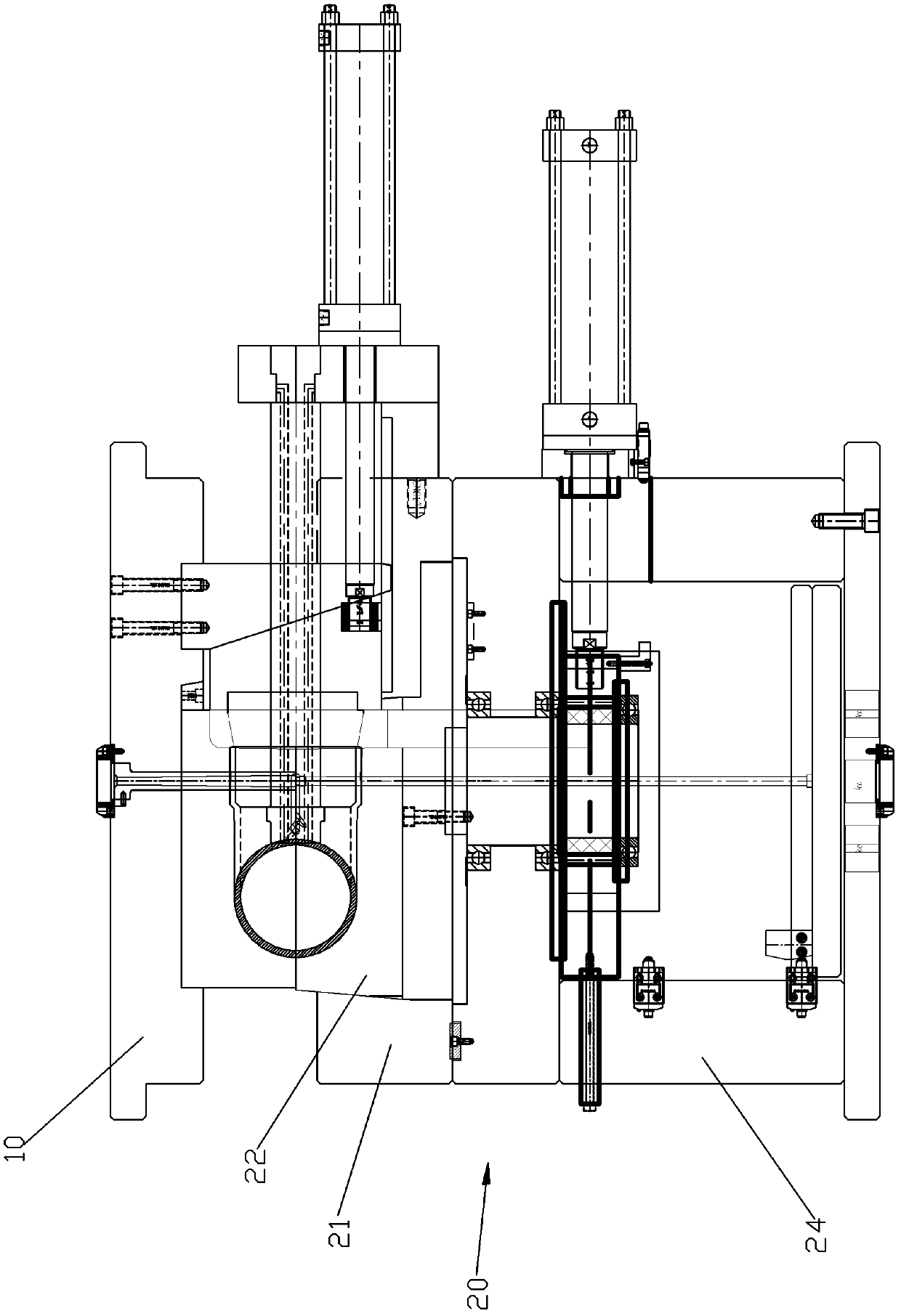

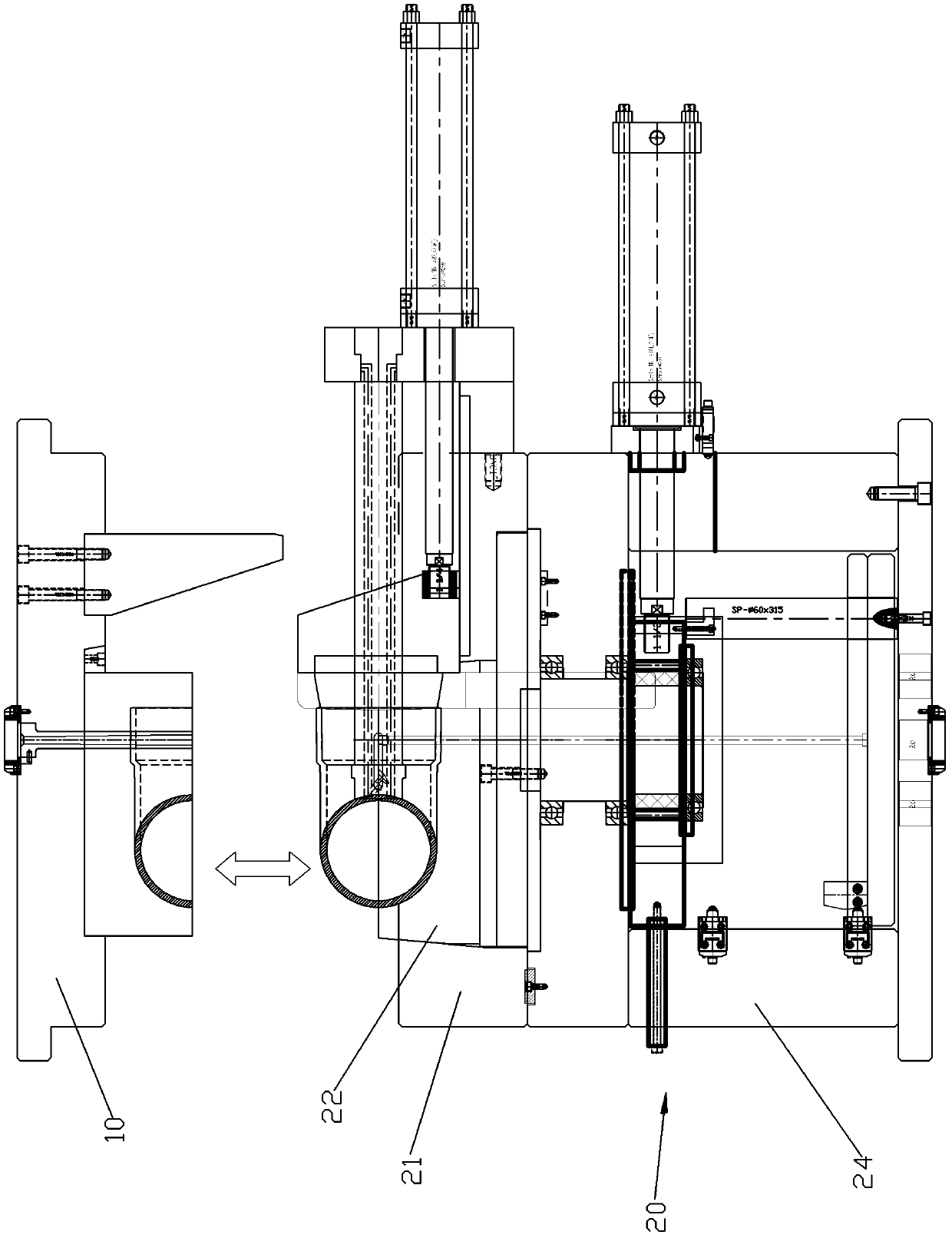

[0028] Please check Figure 1 to Figure 7 , U-shaped pipe mold device, which includes a mold and a core device installed in the mold, which is used to form U-shaped pipe 40.

[0029] The mold includes an upper template 10 and a lower template unit 20, and an up and down pushing mechanism is set between the upper template and the lower template unit. The upper formwork 10 and the lower formwork unit 20 cooperate to form a mold cavity adapted to the U-shaped pipe. The upper template 10 is provided with a downward upper half cavity. The lower template unit 20 includes a lower template 21, a U-shaped outer template 22 rotatably connected to the lower template 21, a transmission unit and a first drive unit. The outer template 22 is provided with an upwardly facing lower half cavity, and the upper half cavity and the lower half cavity cooperate to form a mold cavity. The first drive unit is connected to the outer formwork 22 to drive the outer formwork 22 to rotate relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com