Steel self-stacking tray

A pallet and stacking technology, which is applied in the field of steel self-stacking pallets, can solve problems such as high cost, inconvenient adjustment of cargo location, and difficulty in overall relocation, and achieve the advantages of convenient use of the plane, simple and easy technical support, and investment saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

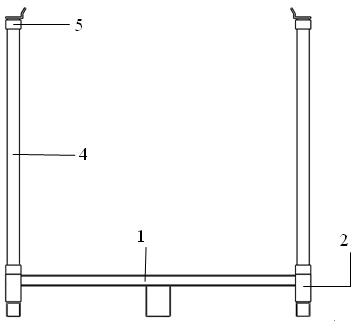

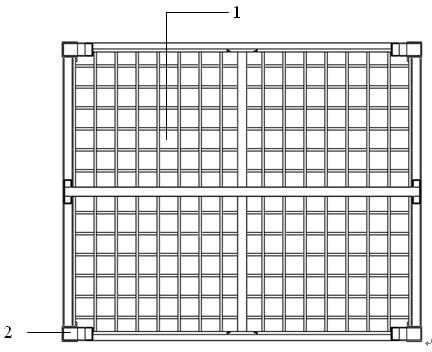

[0038] refer to Figure 1 to Figure 9 , The steel built-in pole self-stacking pallet is composed of a steel pallet, a pole socket, a tray deck, a stacking pole, and a pole deck. [Among them, the steel tray is integrated with the pole socket and the tray holder (referred to as the tray); the stacking pole and the pole holder are integrated (referred to as the pole). ]

[0039] The stacking pole can be freely inserted and pulled out in the pole socket.

[0040] When the tray is used alone, there is no need to insert the pole. When the pallet needs to be self-stacked, insert the 4 poles into the pole socket to form a pallet rack. The forklift drops the second pallet into the pole holder to complete the second-layer stacking of pallets. According to the needs of the pallet stacking height and the lifting height of the forklift, the multi-layer stacking is completed in sequence.

[0041] The tray holder and pole holder are bidirectionally self-locking in the same plane to ensu...

Embodiment 2

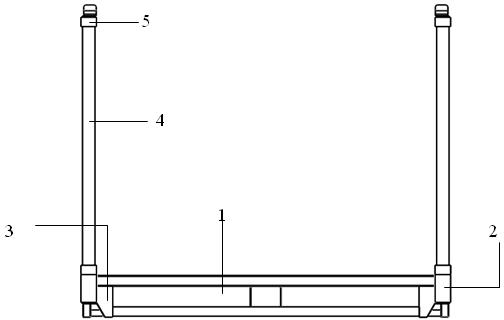

[0043] refer to Figure 10 to Figure 18 , The external pole self-stacking pallet is composed of a steel pallet, a pallet deck, a stacking pole, and a pole deck. [In which the steel pallet is integrated with the pallet holder (referred to as the pallet); the stacking pole and the pole holder are integrated (referred to as the pole)].

[0044] The stacking poles can be freely inserted and pulled out from the tray holder.

[0045] The tray holder and pole holder are bidirectionally self-locking in the same plane to ensure reliable connection and fixation between the tray and the pole.

[0046] When the tray is used alone, there is no need to insert the pole. When pallets need to be self-stacked, insert 4 poles into the pallet holder to form a pallet shelf, and the forklift will drop the second pallet into the pole holder to complete the second-layer stacking of the pallet. According to the needs of the pallet stacking height and the lifting height of the forklift, the multi-la...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap