Automatic high-density three-dimensional storage system

An automatic three-dimensional, storage system technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of delivery of goods to the shelf, large floor area, long body, etc., to achieve small space occupied by the body, narrow lane width, save The effect of removing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

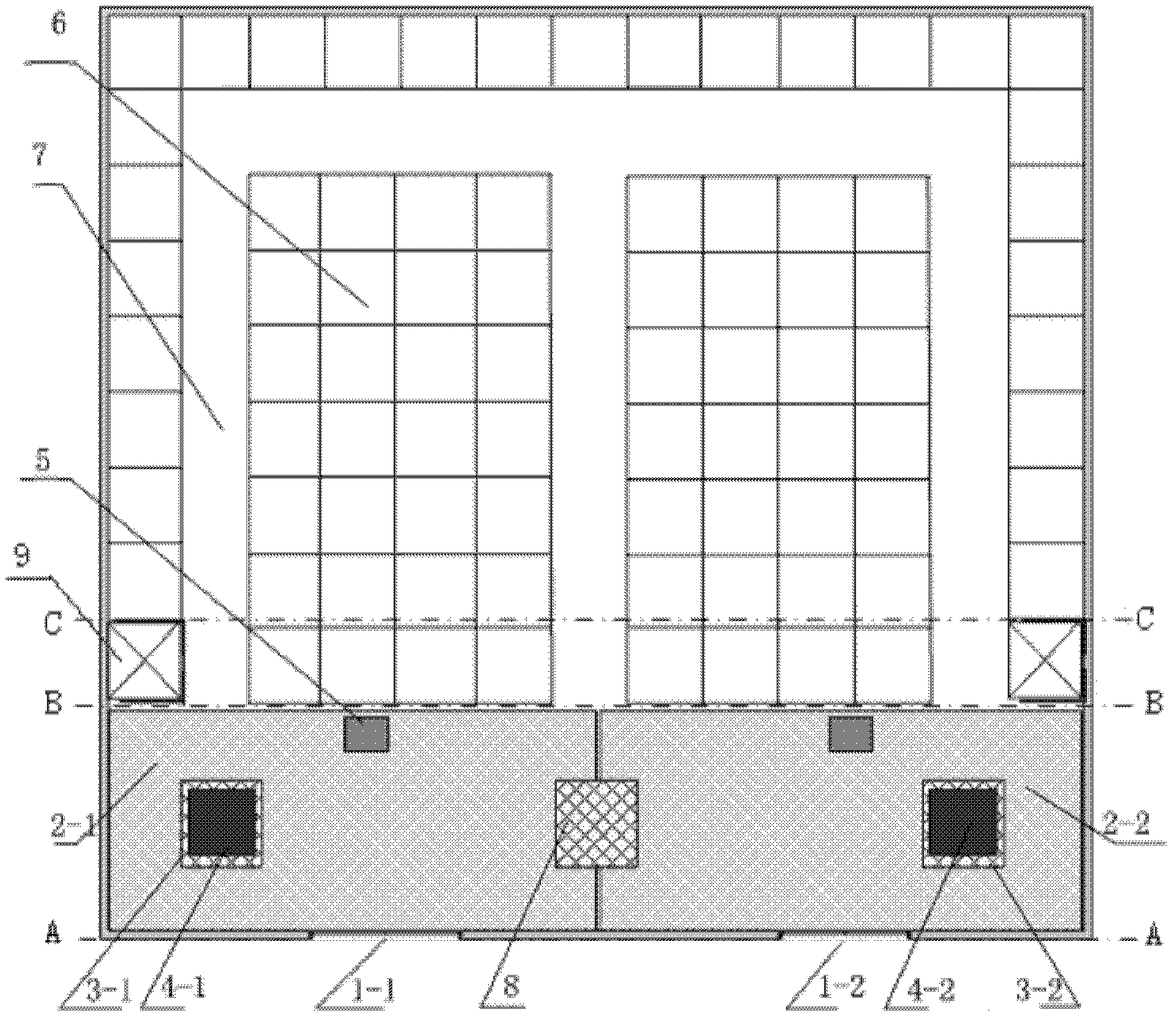

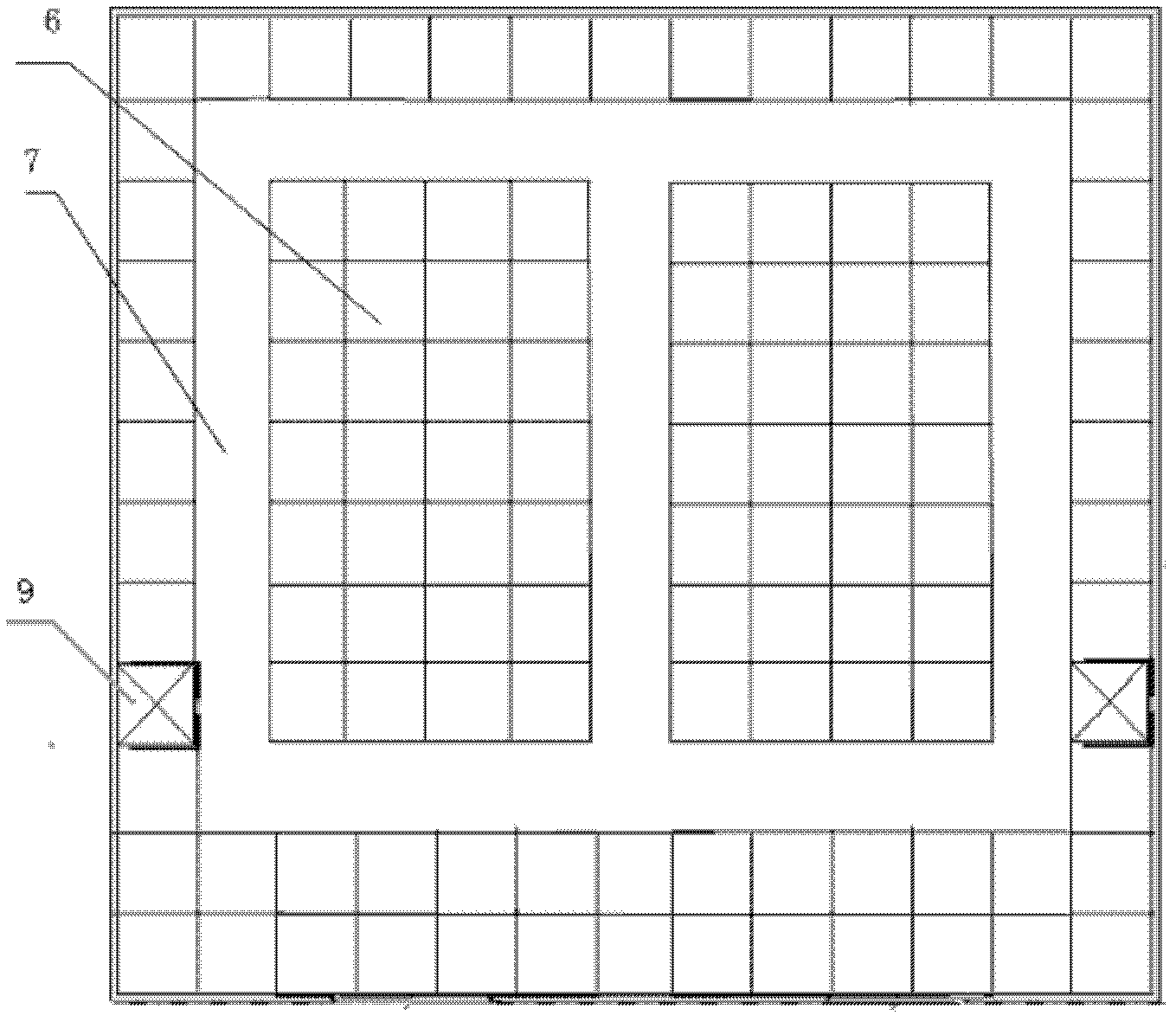

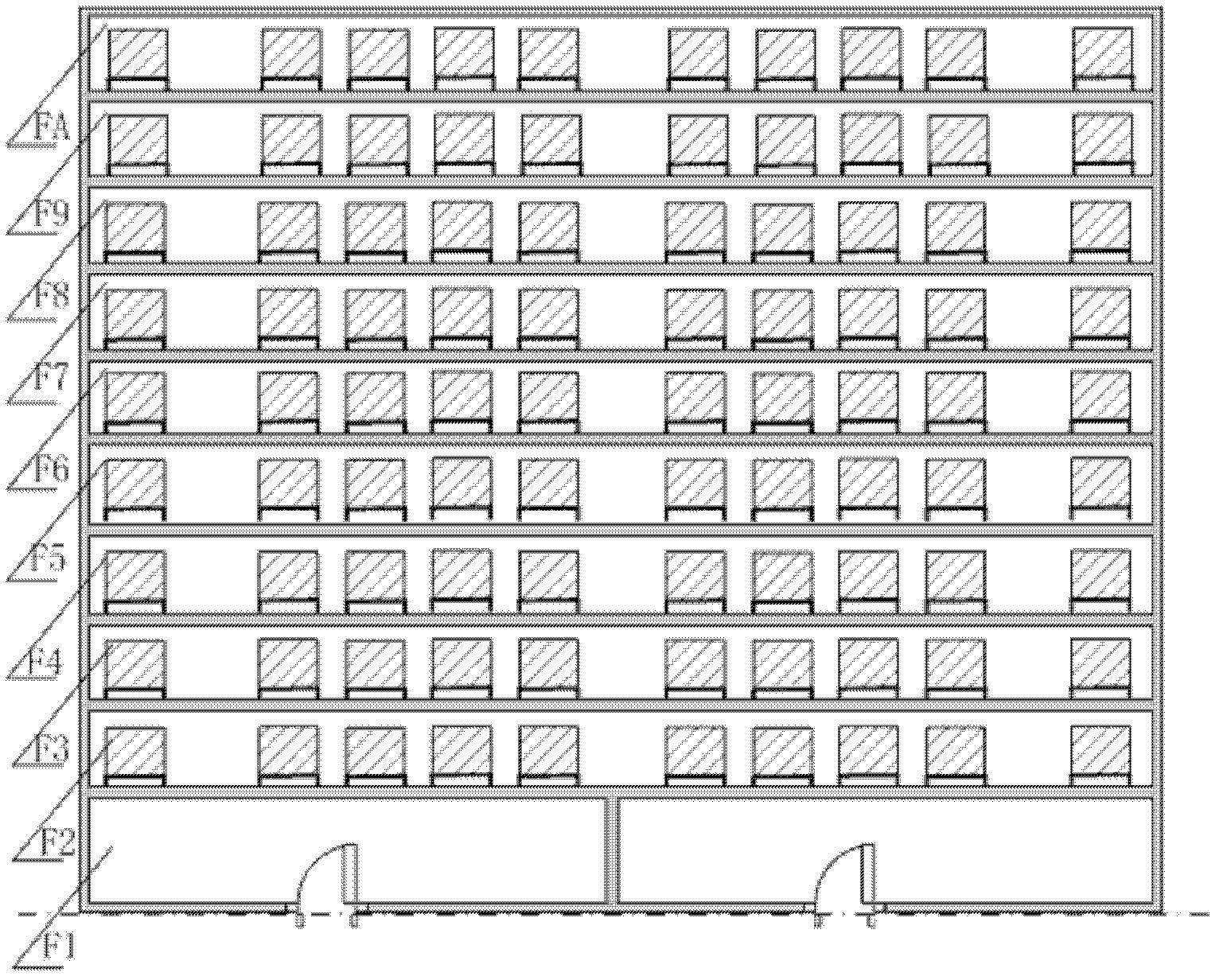

[0031] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0032] A high-density automatic three-dimensional storage system includes a three-dimensional warehouse, a fully automatic transport vehicle and a storage intelligent control system. Such as Figure 1 to Figure 5 As shown, the three-dimensional warehouse is composed of multi-storey warehouses. The goods in each warehouse are stored on the cargo pallets, and the goods are stored in the corresponding cargo positions along with the cargo pallets. The three-dimensional warehouse of this embodiment is a 10-story three-dimensional warehouse constructed of reinforced concrete. Each warehouse is equivalent to a shelf, and its height is slightly higher than the height of standard goods. Vehicle guide signs are laid at intervals on the ground of each warehouse. The vehicle guide mark is composed of RFID tags and QR codes. When the automatic truck passes the R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com