Rectification control system

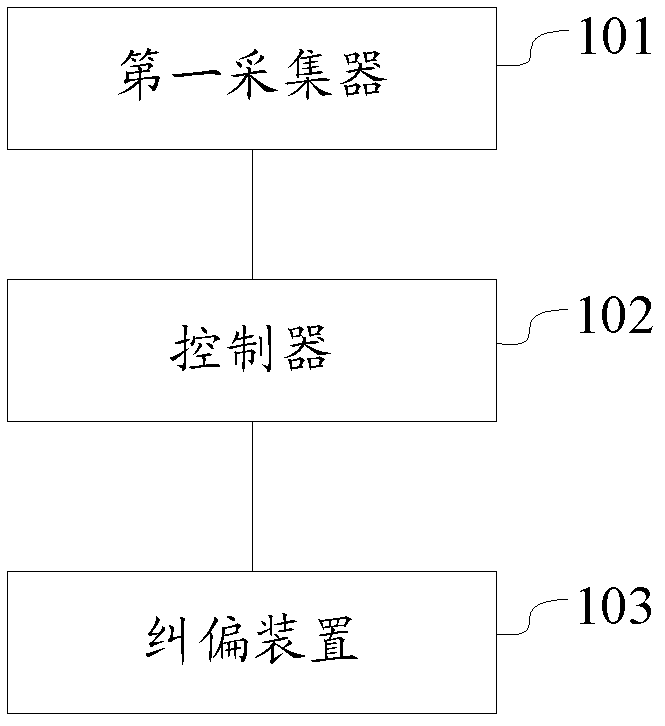

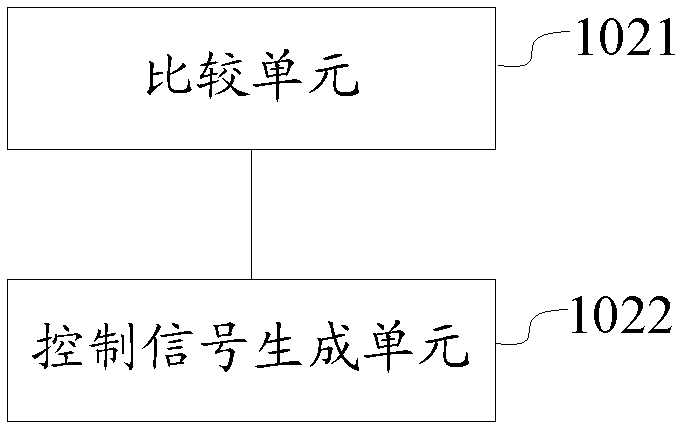

A technology of control system and controller, applied in the field of deviation correction control system, which can solve the problems that the product cannot meet the requirements, offset, and the center line of the strip cannot coincide with the center line of the machine train, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

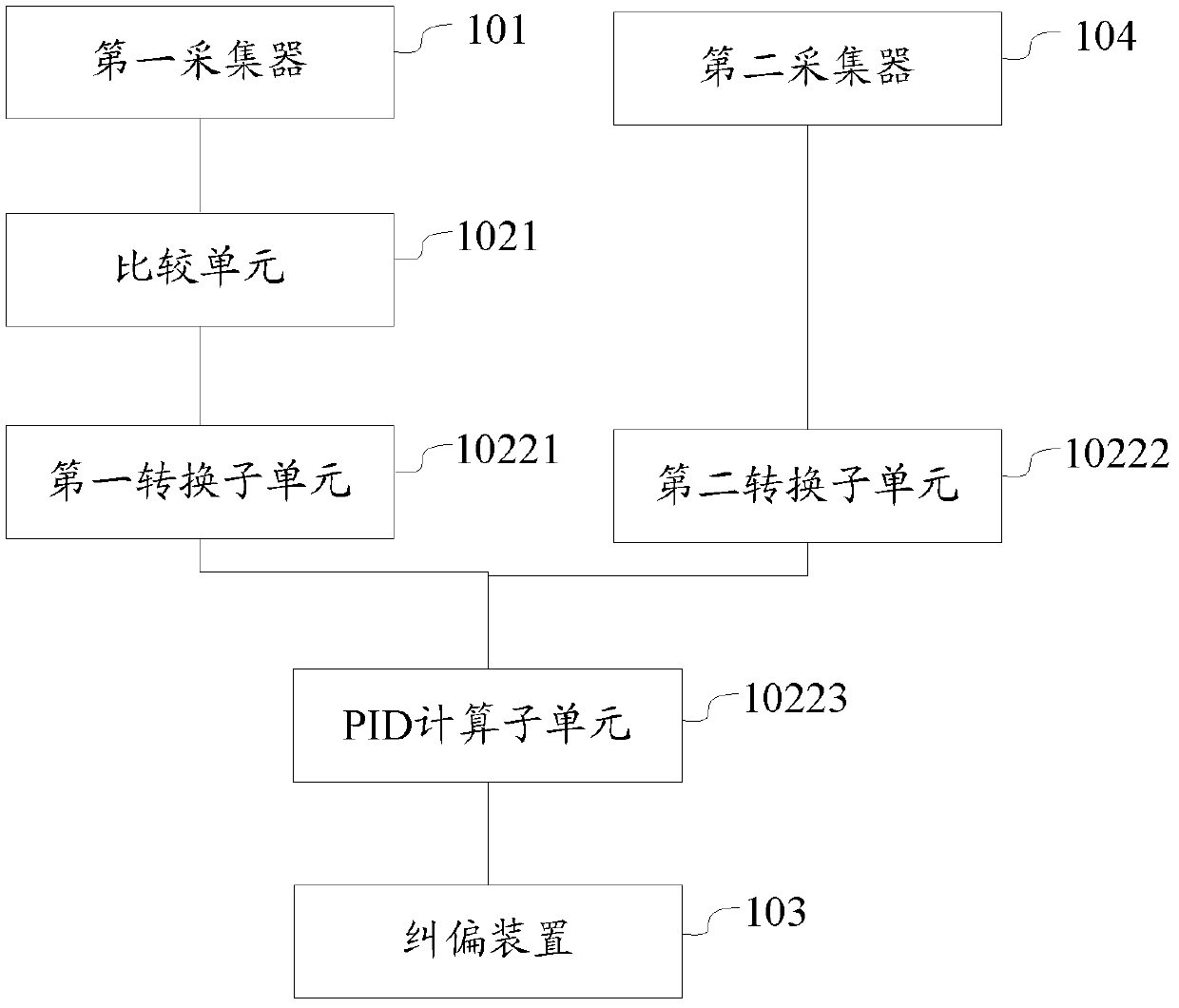

[0102] Corresponding to Embodiment 1 of a deviation correction control system provided by the above-mentioned application, see Figure 9 , shows a flow chart of Embodiment 1 of a deviation correction control method of the present application, including:

[0103] Step S101: When the strip is conveyed on the guide roller, collect the current distance value between the standard line of the strip and the preset fixed point;

[0104] Centering position control (EPC) or edge position control (CPC) is generally used in strip processing. The current distance value between the strip standard line and the preset fixed point includes:

[0105] Collect the current distance value between the strip edge standard line and the preset fixed point;

[0106] or

[0107] Collect the current distance value between the strip center standard line and the preset fixed point.

[0108] Step S102: Comparing the current distance value with a preset standard distance value; judging whether the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com