Martensitic stainless steel and manufacturing method thereof

A technology of martensitic stainless steel and manufacturing method, which is applied in the field of martensitic stainless steel and its manufacturing, can solve the problems of high cost and corrosion resistance only close to the level of 2Cr13, and achieve low cost, easy process control, excellent The effect of corrosion resistance and high hardness

Active Publication Date: 2012-07-25

BAOSTEEL DESHENG STAINLESS STEEL

View PDF10 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, JP2009-203528A guarantees corrosion resistance through high chromium equivalent (15-16.6%), but due to the high carbon content, the corrosion resistance is still at a level close to 2Cr13; FR2920784A has high C and N content, while Cr content is relatively high Low (10-12.4%), the loss of corrosion resistance is guaranteed to be compensated by adding Mo, but the corrosion resistance can only reach a level close to 2Cr13; the alloy composition system co

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

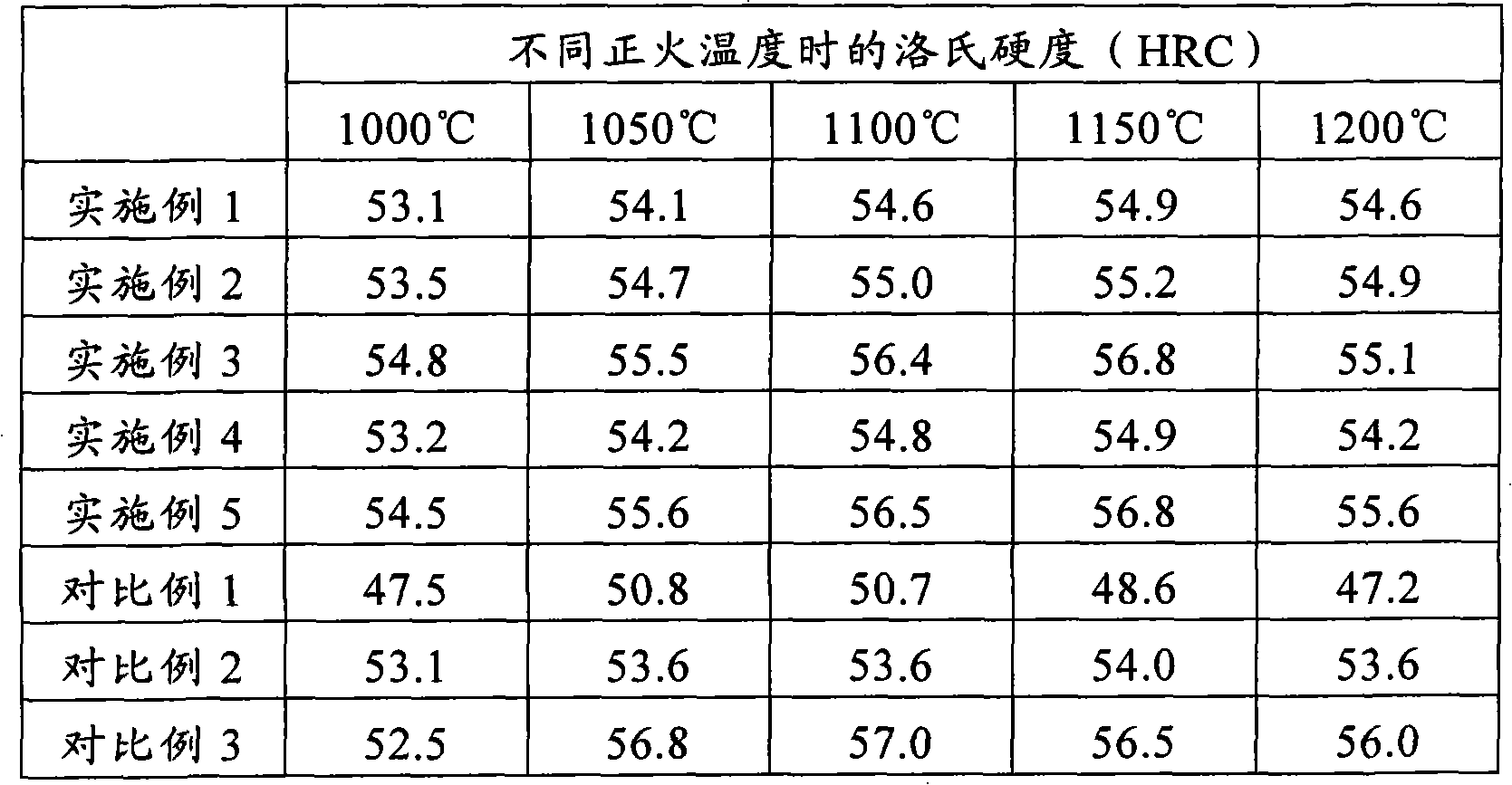

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to martensitic stainless steel. The martensitic stainless steel comprises the following chemical components in percent by weight: 0.13-0.23% of C, less than 1.0% of Si, less than 1.0% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 12.0-14.0% of Cr, 0.070-0.120% of N, less than 1.0% of Ni, 0.9-1.5% of Mo, and the balance of Fe and inevitable impurities, wherein the content of C and N meets the formula as follows: the sum of C and N is larger than or equal to 0.20% and is less than or equal to 0.33%. The steel is manufactured by the following steps of: heating a steel billet or a continuous casting billet at the temperature ranging from 1100 DEG C to 1250 DEG C, carrying out rolling, and finishing final rolling at the temperature more than 900 DEG C; then carrying out annealing treatment with the annealing temperature of 800-900 DEG C and the annealing time of 4-8 hours; and then carrying out normalizing treatment with the normalizing temperature of 1000-1200 DEG C and the normalizing time of 2-5 hours. The martensitic stainless steel has good machining performance and excellent corrosion resistance after heat treatment, and is suitable for being used for manufacturing molds, surgical and medical instruments, knives and scissors and the like.

Description

technical field [0001] The invention relates to a martensitic stainless steel used for manufacturing moulds, surgical and medical instruments, knives, scissors, etc. and a manufacturing method thereof, which has good machining performance and excellent corrosion resistance after heat treatment. Background technique [0002] Compared with other types of stainless steel, martensitic stainless steel has the advantages of high hardness, strong wear resistance and low cost, so it is widely used in molds, knives and scissors, surgery and medical equipment and other industries. These industries require steel to have sufficient hardness and wear resistance, and the requirements for corrosion resistance are getting higher and higher, and the cost problem is also becoming more and more prominent. From the perspective of composition design, traditional martensitic stainless steel (such as 2Cr13, 3Cr13, 4Cr13 series) mainly controls the hardness of the steel after heat treatment by cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/22C22C33/04

Inventor 马永柱秦斌

Owner BAOSTEEL DESHENG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com