Weft breakage detection device with function of simple setting

A detection device and function technology, applied in textiles, textiles, papermaking, looms, etc., can solve problems such as empty weft phenomenon, lower yield rate of woven products, shortage of weft threads in woven products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

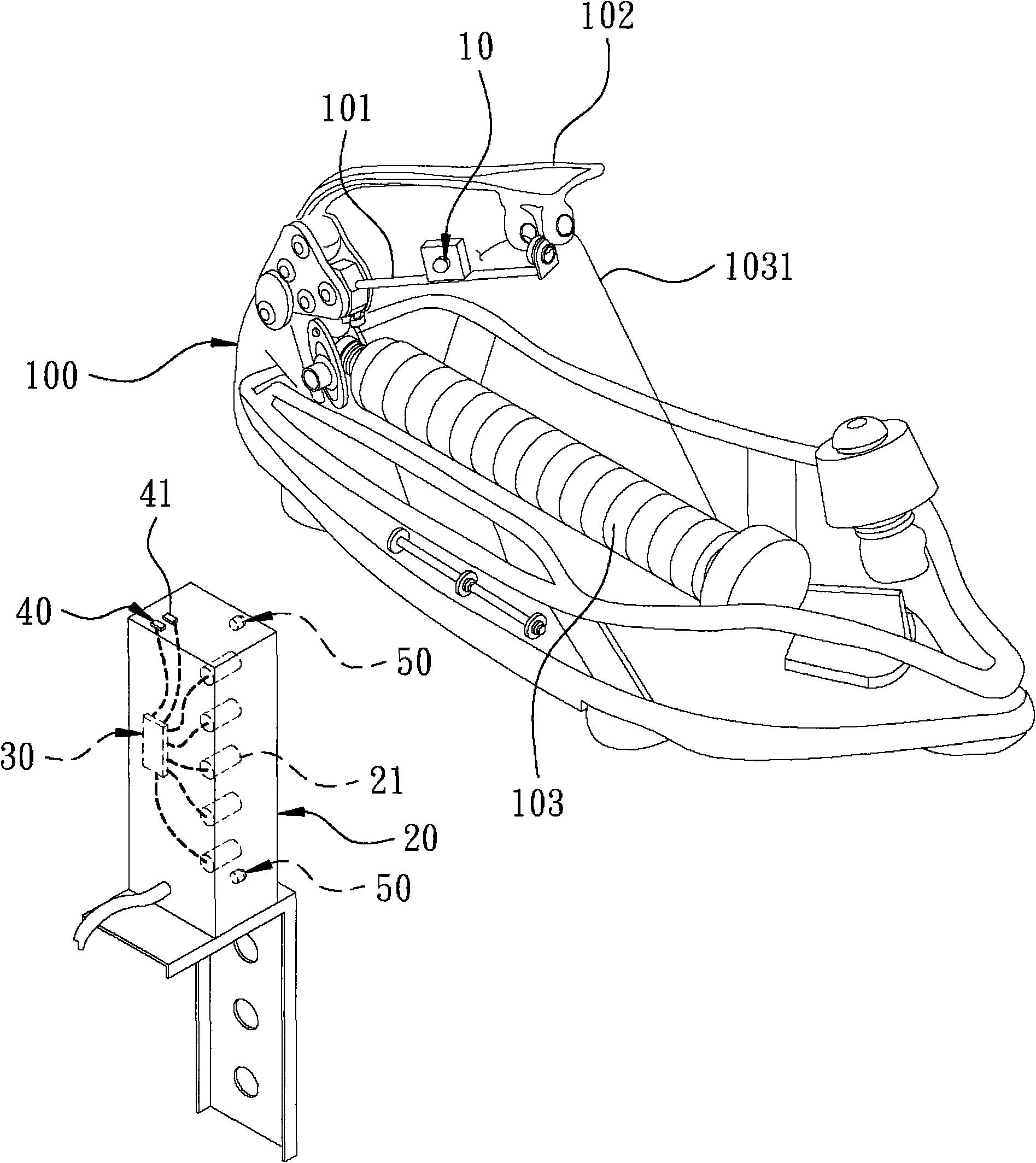

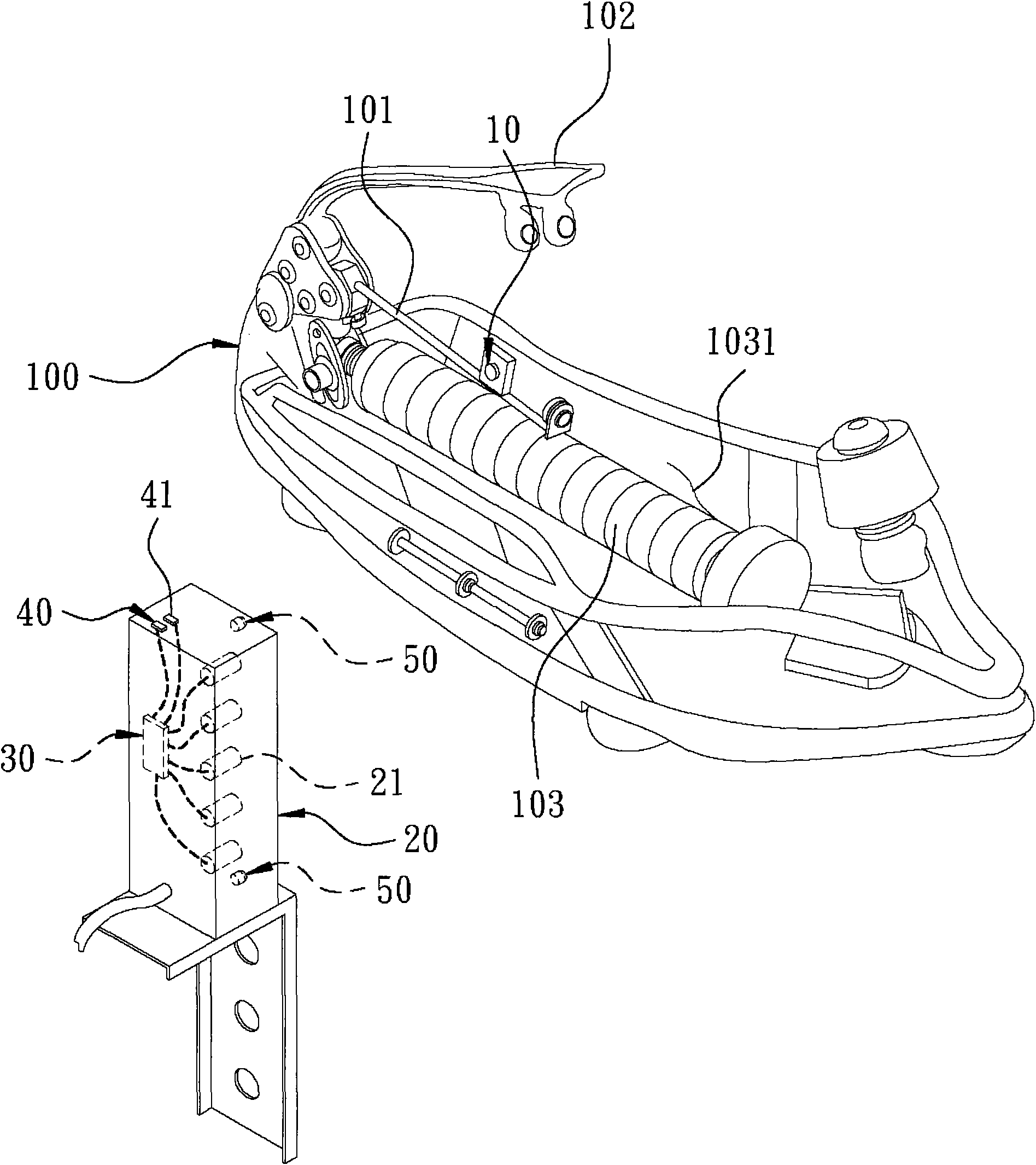

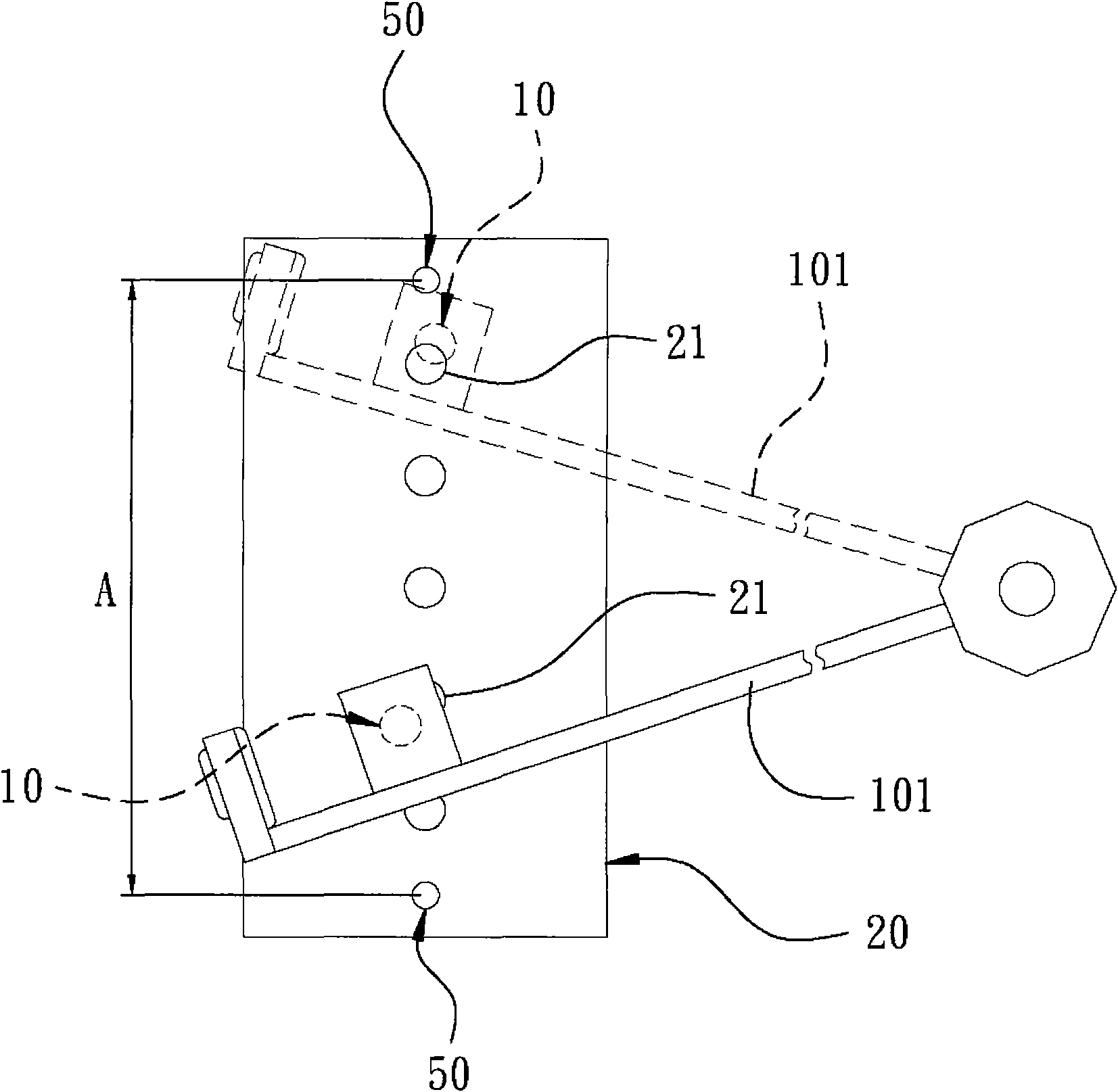

[0022] First, see figure 1 and figure 2 Shown is the schematic diagram of the present invention in the unbroken state of the weft yarn and the schematic diagram of the broken state of the weft yarn; the present invention includes:

[0023] An induction source 10, in the embodiment of the present invention, the induction source 10 is a permanent magnet, and is installed on a yarn-drawing bar 101 of a shuttle boat 100, and can move with the deflection of the yarn-drawing bar 101, and In the present invention, the shuttle boat 100 is respectively provided with a weft yarn guide rod 102 and a weft yarn bobbin 103, and the weft yarn guide rod 101 can swing between the weft yarn guide rod 102 and the weft yarn bobbin 103, and generally has a first state And a second state, and the first state is the position where the yarn drawing rod 101 is close to the weft yarn guide rod 102 (that is, the yarn drawing rod 101 is pulled by the weft yarn 1031 on the weft yarn bobbin 103), the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com