Public exhaust passage

A technology for exhaust ducts and air intakes, applied in vertical pipes, building components, buildings, etc., can solve the problems of expensive freight, heavy weight, difficult waterproofing, etc., to ensure permanent use, ensure exhaust efficiency, The effect of easy waterproof treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

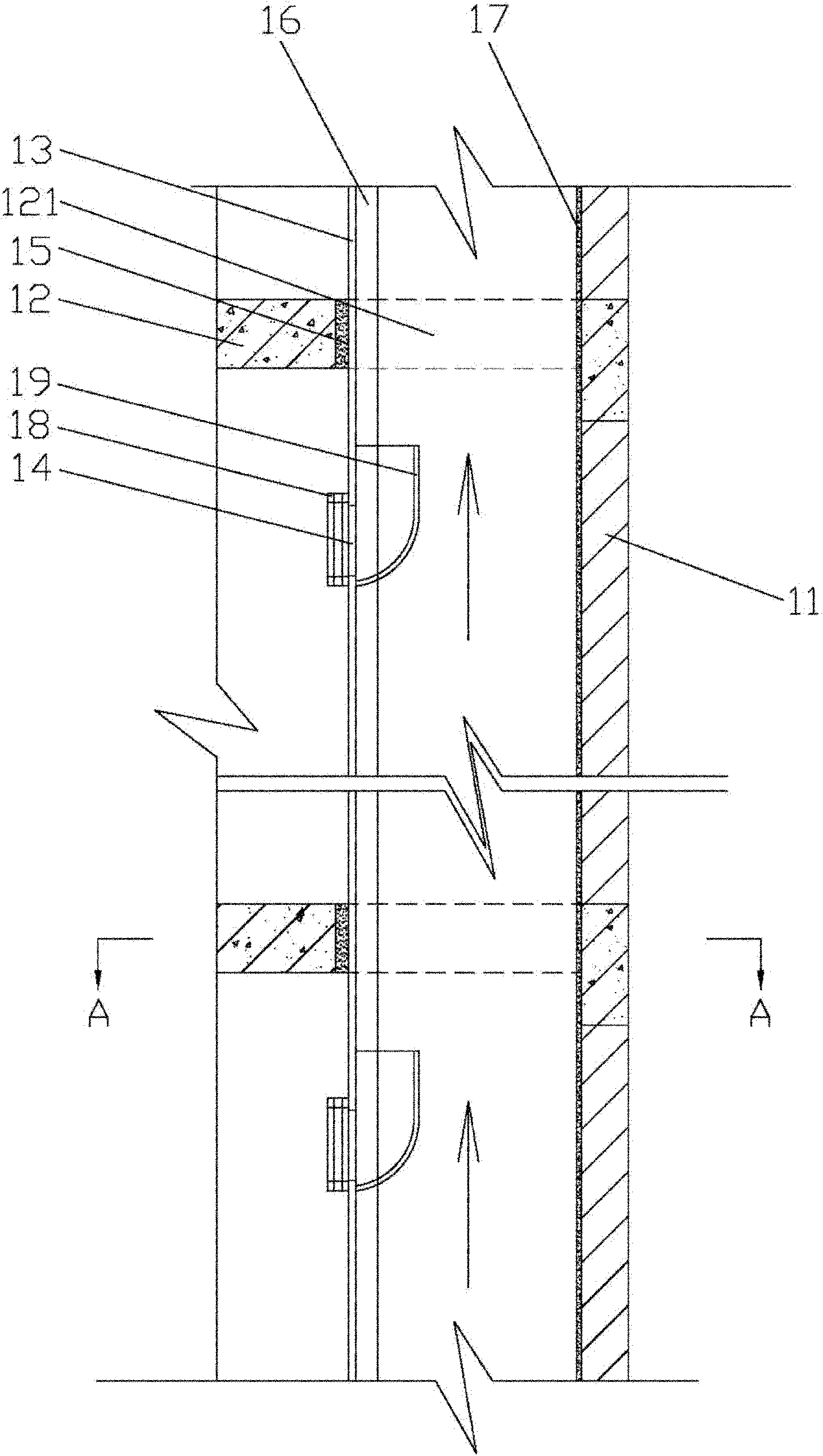

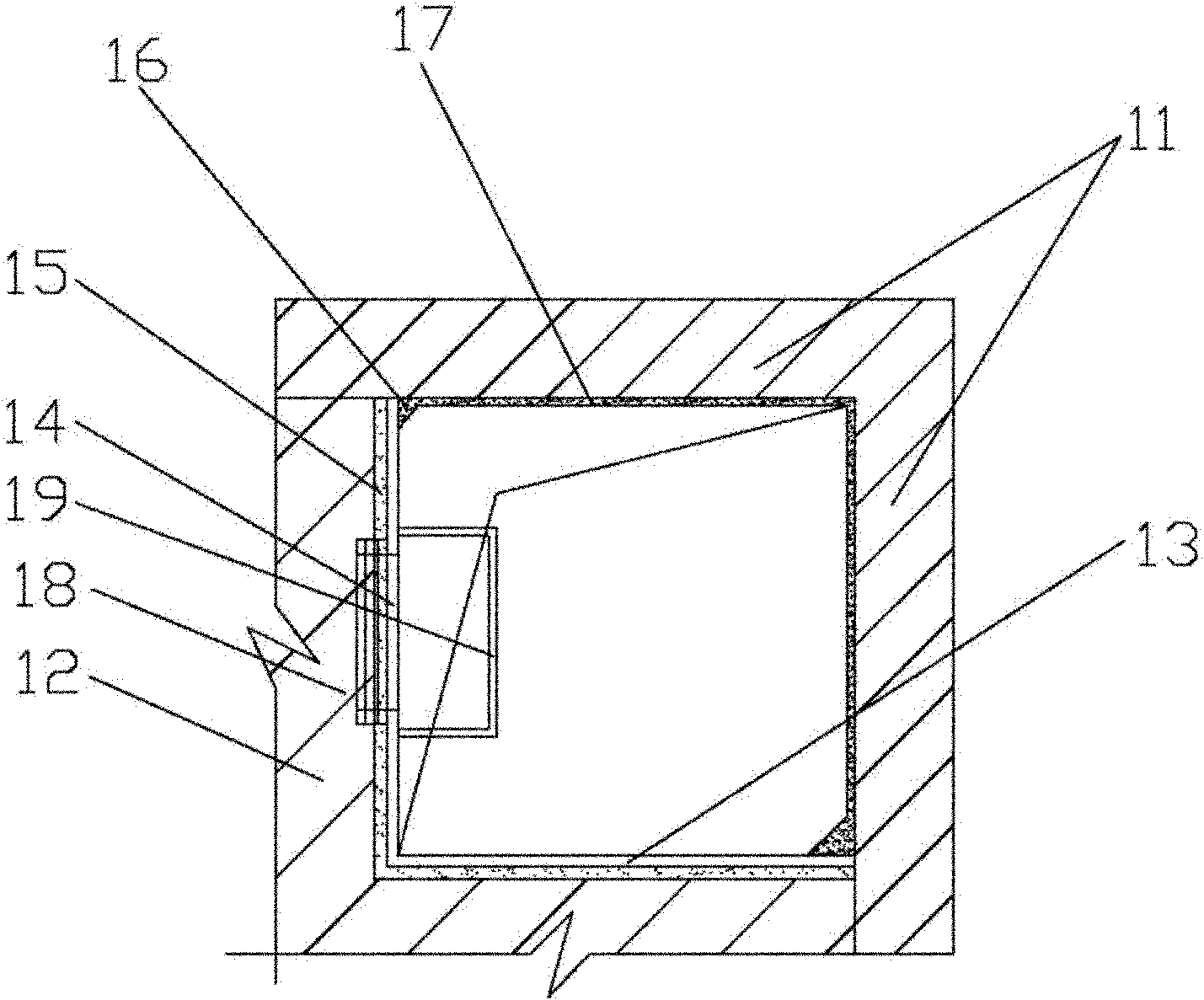

[0033] Such as figure 1 and figure 2 As shown, the common exhaust duct provided by the first embodiment is installed at the inner corner 11 of the room, and an opening 121 is opened at the inner corner 11 of each floor 12, and the L-shaped thin-walled structure 13 encloses the opening 121 and the inner corner 11 walls form a common exhaust duct, and several air inlets 14 are provided on the common exhaust duct. Check valves 18 are installed at 14 places of the air inlet, and an upward guiding pipe 19 with an opening is arranged on the inner side of the air inlet 14.

[0034] In this embodiment, the L-shaped thin-walled structure 13 passes through the hole 121, and the gap between the L-shaped thin-walled structure 13 and the floor 12 is filled with cement mortar 15, which ensures effective sealing between the upper and lower floors and the firm and reliable installation of the L-shaped thin-walled structure .

[0035] In this embodiment, a check valve 18 is installed at the...

Embodiment 2

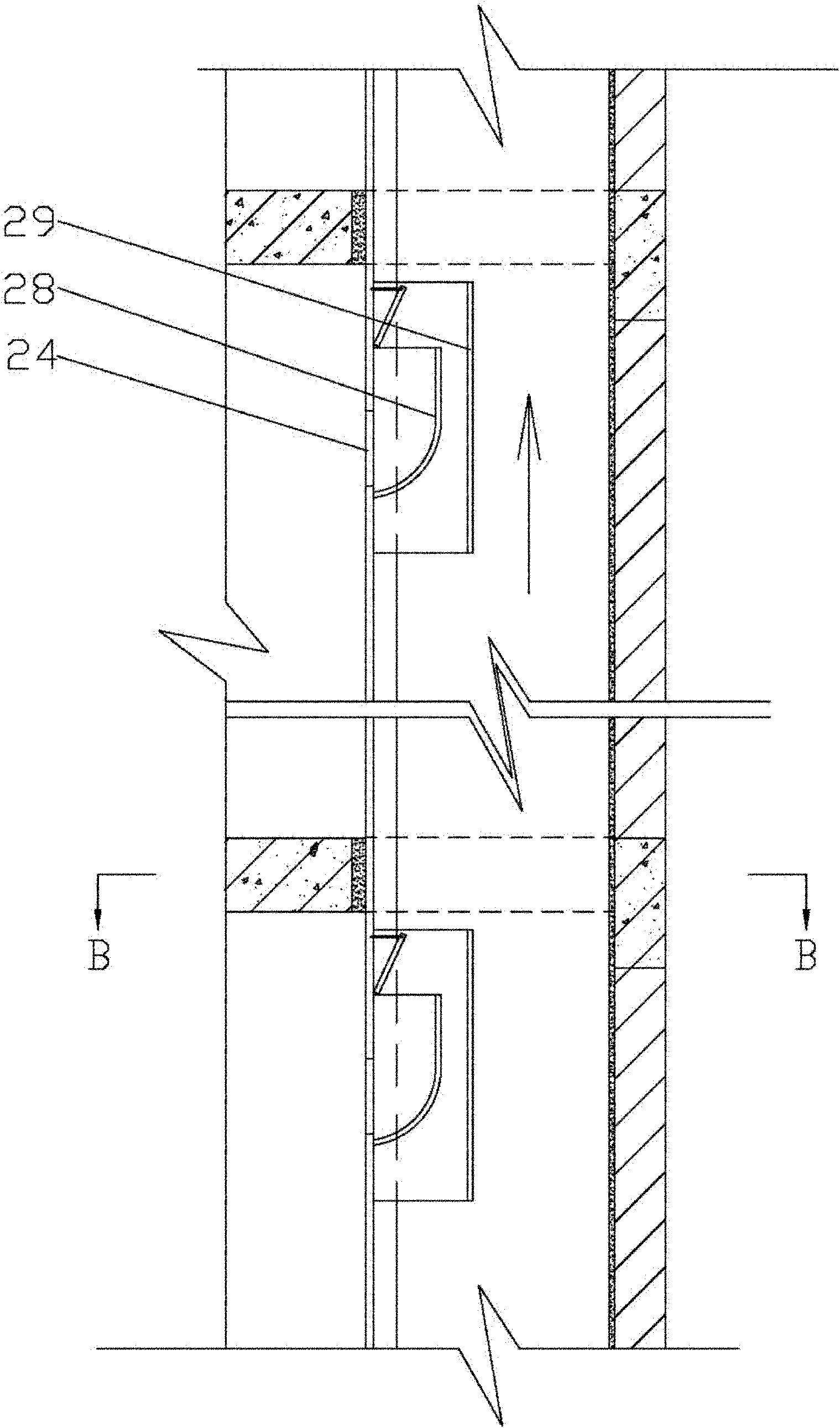

[0044] Such as image 3 and Figure 4 As shown, compared with Embodiment 1, the difference of Embodiment 2 is that a fire damper 28 and a Venturi plate 29 are installed inside the air inlet 24, thereby ensuring that when a fire occurs, the fire damper 28 operates and the passage is cut off. Prevent fire from spreading. The Venturi plate 29 improves the pressure-changing air extraction function of the common exhaust duct system, so that the exhaust gas can be discharged more smoothly. The similarities will not be repeated here.

Embodiment 3

[0046] Such as Figure 5 and Figure 6 As shown, the common exhaust duct provided by the third embodiment is installed at the inner corner 31 of the room, and an opening 321 is opened at the inner corner 31 of each floor 32, and an L-shaped thin-walled structure 33 is installed between each floor 32 , the L-shaped thin-walled structure 33 encloses the wall of the hole 321 and the inner corner 31 to form a common exhaust duct, and the common exhaust duct is provided with a number of air inlets 34, and a fire damper 36 is installed at the air inlet 34.

[0047] In this embodiment, the L-shaped thin-walled structure 33 is installed on the floor 32, that is, the L-shaped thin-walled structure 33 does not need to pass through the opening 321. This installation method solves the self-supporting problem of the L-shaped thin-walled structure 33, that is, the floor 32 The self-weight of the L-shaped thin-walled structure 33 can be supported.

[0048] In this embodiment, the L-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com