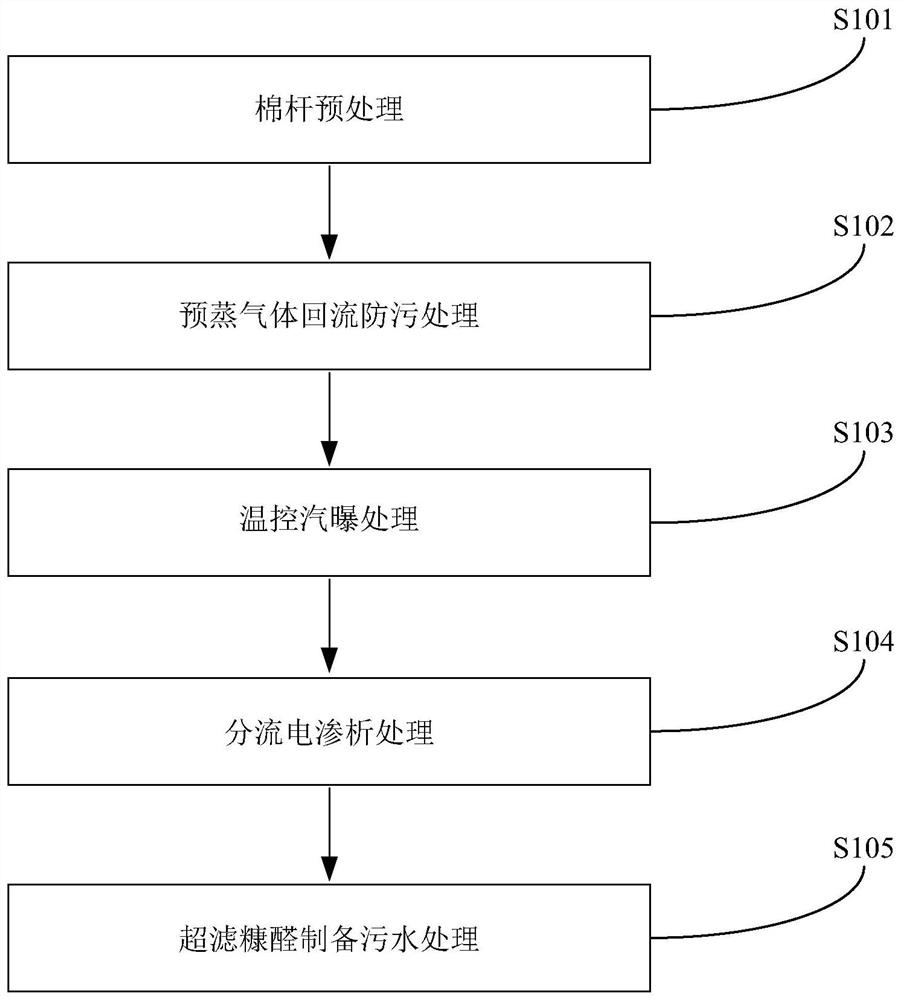

Method for preparing furfural by extracting xylose through steam explosion of cotton stalks and fully utilizing furfural

A technology of furfural and cotton stalks, which is applied in the field of extraction of xylose by steam explosion from cotton stalks to prepare furfural and its full utilization. Control, ensure exhaust efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

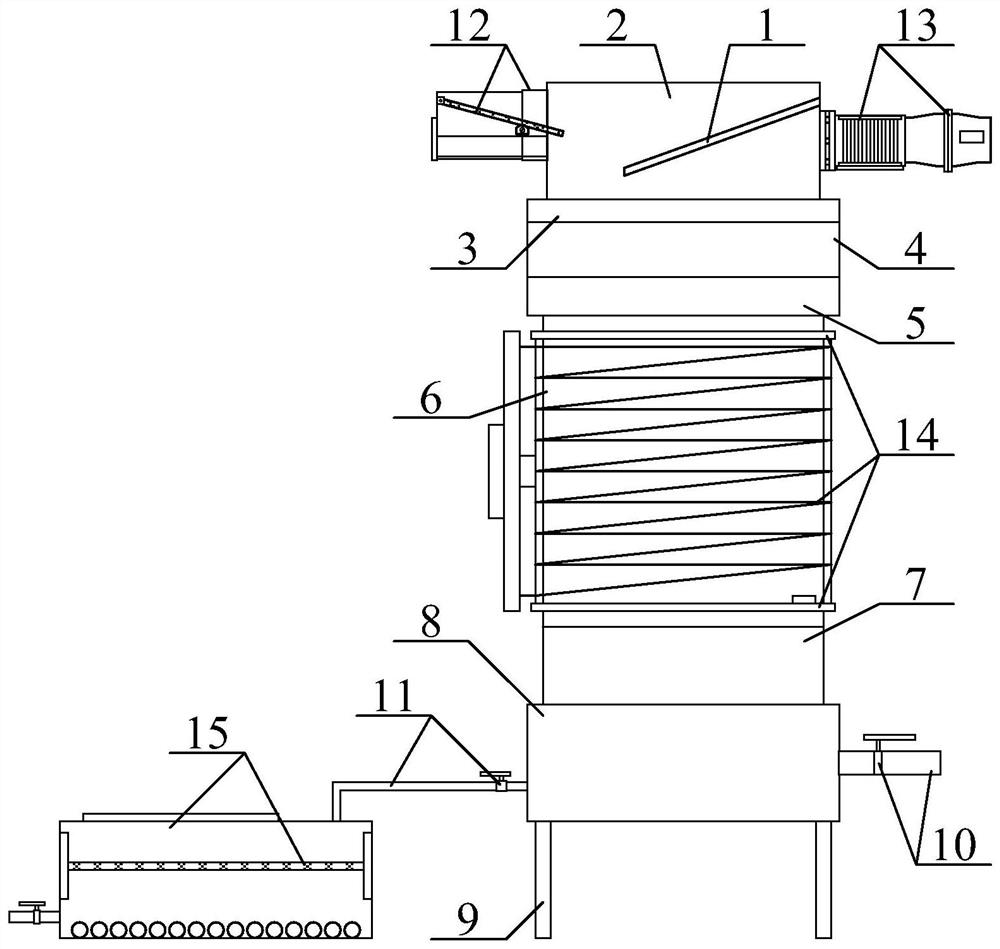

[0030] The present invention will be further described below in conjunction with accompanying drawing:

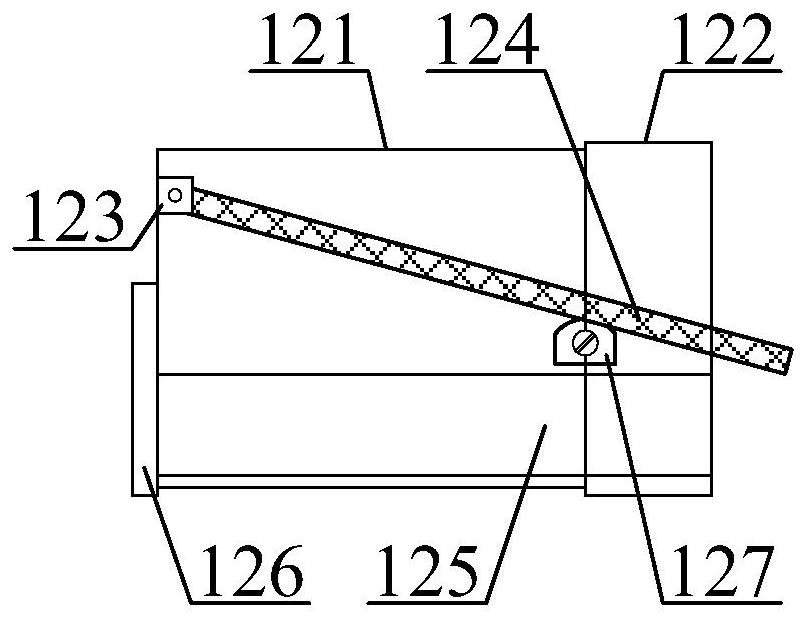

[0031] In the picture:

[0032] as attached figure 2 to attach Image 6 shown

[0033] A device for preparing furfural by extracting xylose by steam explosion of cotton stalks, comprising a separator 1, a feed box 2, a spiral steamer 3, a steam aerator 4, a pulp washer 5, a furfural splitting tower 6, a furfural rectification tower 7, furfural Storage tank 8, supporting legs 9, discharge valve 10, sewage pipe with valve 11, cotton stalk filter miscellaneous import box structure 12, furfural preparation gas anti-pollution treatment fan structure 13, temperature-controlled heating insulation cylinder structure 14 and waste water anti-pollution discharge Processing box structure 15, the upper right end of the partition plate 1 is bolted to the inner upper right wall of the feed box 2; the outlet of the lower part of the feed box 2 is bolted to the upper inlet of the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com