an exhaust pipe

A technology for exhaust pipes and exhaust outlets, which is applied in the direction of exhaust devices, machines/engines, mechanical equipment, etc., and can solve the problems of corrosion of exhaust pipes, reduced exhaust efficiency of exhaust pipes, and easy inhalation or flushing of accumulated water Problems in the exhaust tube, etc., to achieve the effect of prolonging the service life, ensuring normal use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

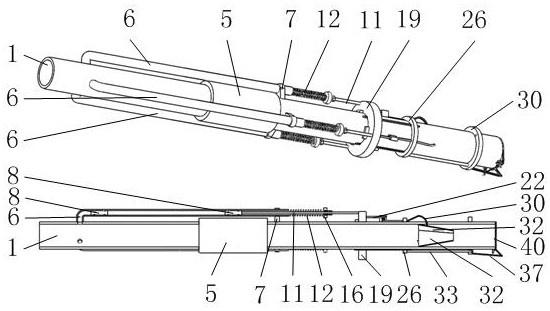

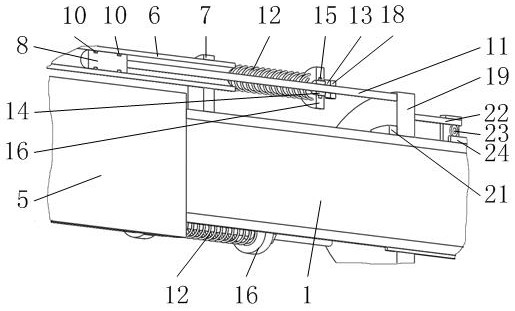

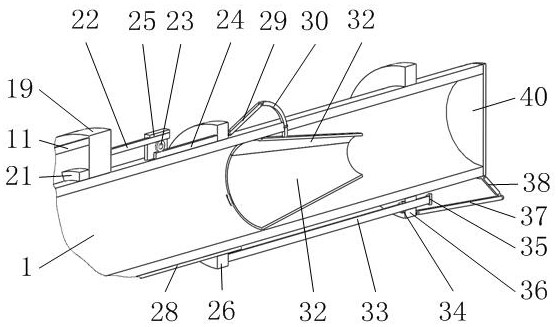

[0030] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0031] Such as figure 1 , 2 , 3, it includes exhaust cylinder 1, muffler 5, pressure divider 6, slide plug 8, screw 11, spring A12, ring sleeve C19, limit block A21, ring sleeve D26, connecting rod A29, arc Rod 30, cone plate 32, guide rod 33, ring sleeve E36, connecting rod B37, swing bar 38, swing shaft 39, cover plate 40, spring B44, wherein as figure 1 As shown, the exhaust cylinder 1 equipped with the muffler 5 is evenly installed in the circumferential direction with three pressure divider pipes 6 communicating with the end of the exhaust cylinder 1 close to the engine, and the three pressure divider pipes 6 are parallel to the exhaust cylinder 1; Two sliding plugs 8 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com