A Control Method for Preventing Excessive Adjustment of Boiler Coal Feeding During Load Variation

A control method and variable load technology, applied in the direction of adjusting fuel supply, combustion method, and combustion control, etc., can solve the problems of insufficient boiler coal quantity, unseen boiler load control system scheme, affecting unit stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

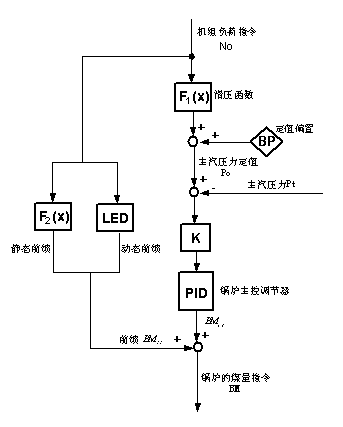

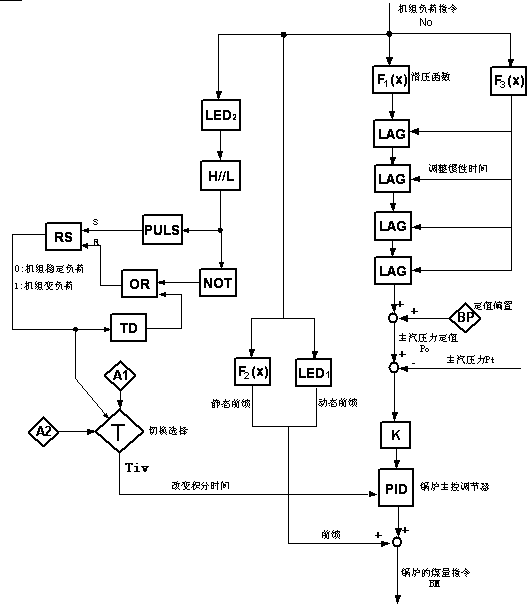

[0036] The present invention will be described below with reference to the accompanying drawings.

[0037] A control method invented to prevent excessive adjustment of boiler coal supply in the process of variable load is realized through the following technical solutions:

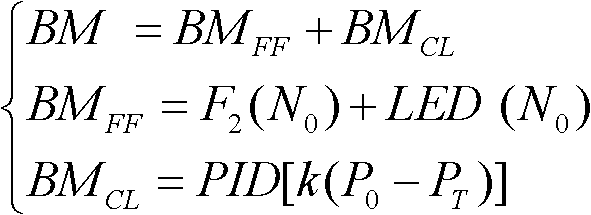

[0038] The set value of the main steam pressure of the unit is:

[0039] P 0 =LAG(LAG(LAG(LAG(F 1 (N 0 )))))+BP

[0040] In the formula, N 0 is the load command of the thermal power unit; P 0 It is the set value of the main steam pressure of the unit; BP is the manual adjustment offset of the set value of the main steam pressure; F 1 (g) is a preset sliding pressure function, which can be set according to the load command N of the unit 0 to calculate the set value of the main steam pressure; LAG is an inertia link with variable parameters, and its transfer function expression is:

[0041] LAG ( s ) = 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com