Multi-path high-accuracy hydraulic loading/unloading servo control system suitable for model test

A servo control system and model test technology, applied in the field of geotechnical engineering, can solve the problems of unsatisfactory loading and unloading accuracy and long-term pressure holding effect, and can not realize step-by-step unloading, so as to save money, reduce construction costs, and increase pressure holding. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

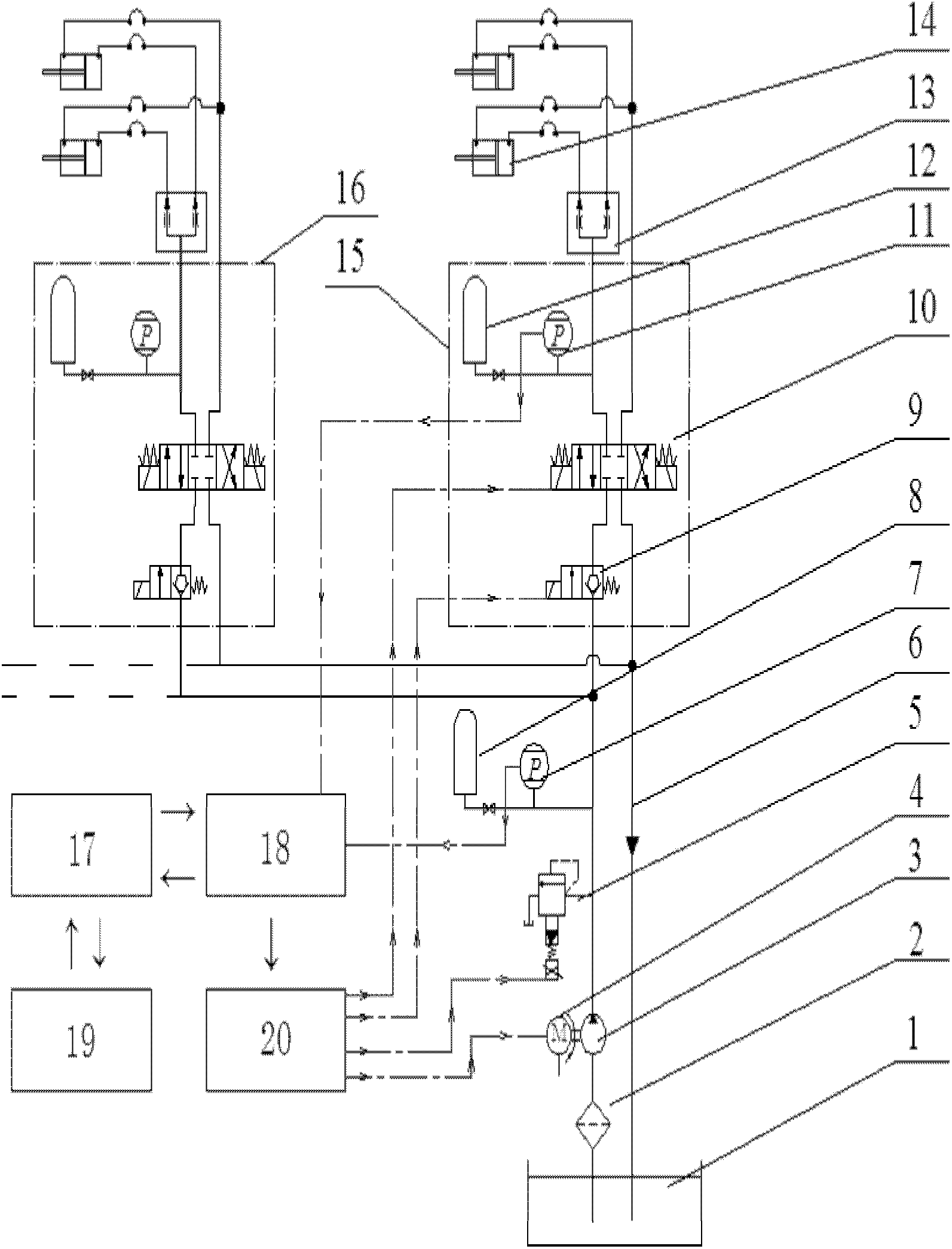

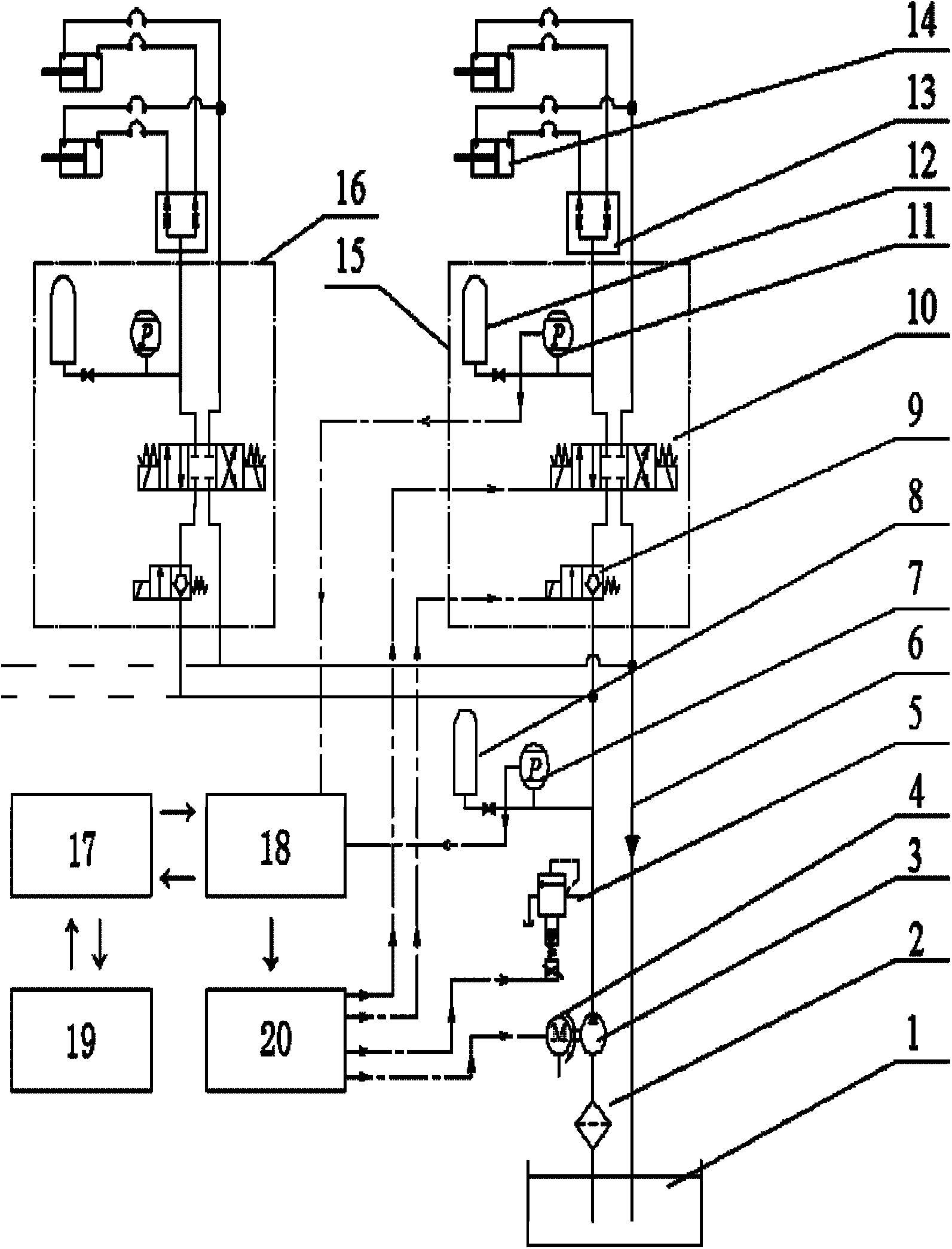

[0032] A multi-channel high-precision hydraulic loading and unloading servo control system suitable for model tests, including a hydraulic station, a loading and unloading control system, a total oil circuit, an oil distribution circuit, and an oil distribution circuit including the first oil circuit 15 and the second oil circuit 16 , the hydraulic station is connected to the total oil circuit, the total oil circuit and the first oil circuit 15, the second oil circuit 16 is connected by the connecting pipeline 8, the first oil circuit 15, the second oil circuit 16 and the diverter valve 13 and double The action oil cylinder 14 is connected, and the loading and unloading control system is respectively connected with the control hydraulic station, the total oil circuit and the first oil circuit 15, and the second oil circuit 16. The loading and unloading c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com