High-temperature liquid metal magnetic force driving pump

A magnetic drive pump and liquid metal technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of high temperature demagnetization, service reliability and life limitation, to increase the maximum pressure head, increase the maximum flow rate, save costs and effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

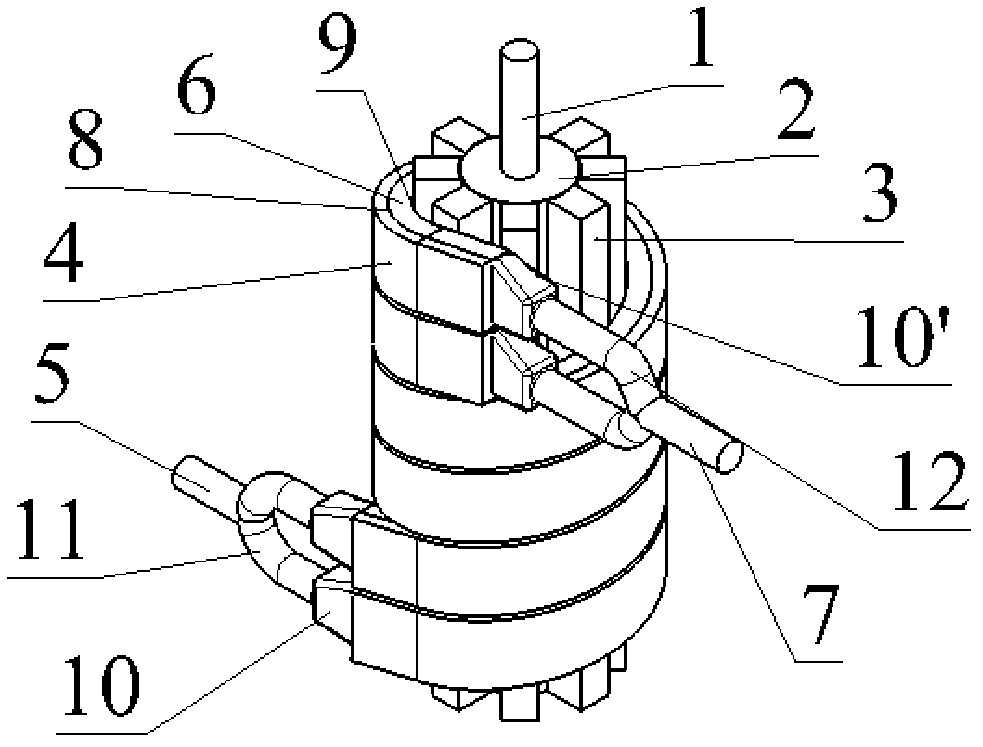

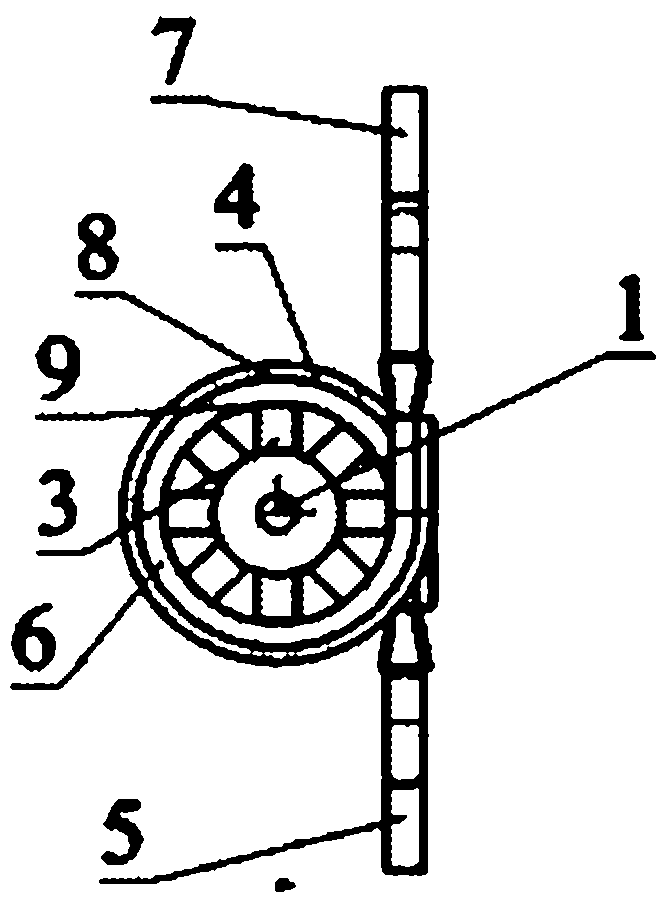

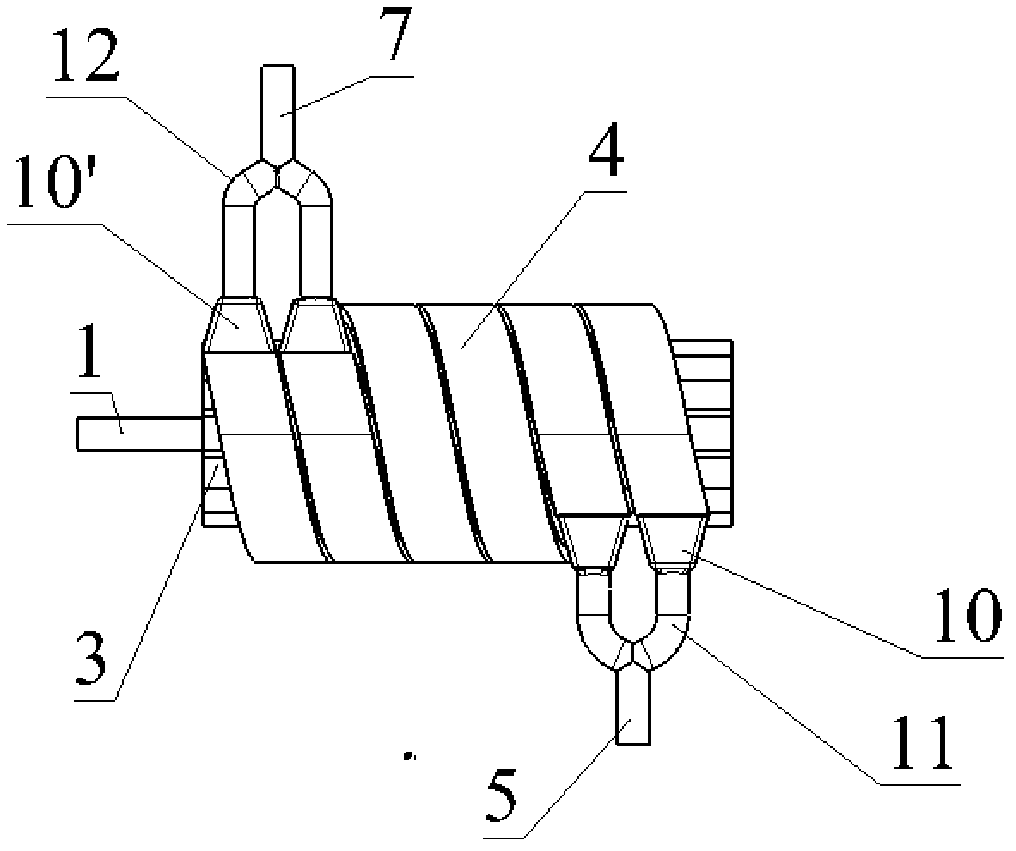

[0018] Such as figure 1 , 2 , 3, the embodiment of the present invention includes: a rotating motor and a pump body, the pump body includes a wound rotor 3, a pump channel flow channel 6 (using a flat shape), a pump body inlet section 5, a pump body outlet section 7, an inlet transition Section 10, outlet transition section 10', inlet runner 11 and outlet runner 12. The wound rotor with the mainstream current is installed on the weighing cylinder 2 connected with the shaft 1 of the squirrel-cage rotating motor. Eight magnetic poles 3 are installed on the wound rotor, and the magnetic poles are provided with copper conductors. When the conductor is excited, the direct current direction of the adjacent magnetic poles 3 is opposite, so that the polarities of the adjacent magnetic poles 3 are opposite, forming the effect of N and S poles arranged alternately; when the liquid metal at high temperature (>300°C) enters through the inlet section 5 of the pump body, it bifurcates int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com