concrete spraying manipulator

A concrete spraying and manipulator technology, applied in manipulators, program-controlled manipulators, earth-moving drilling, etc., can solve the problems of limited construction conditions, difficult turning of wheeled chassis, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

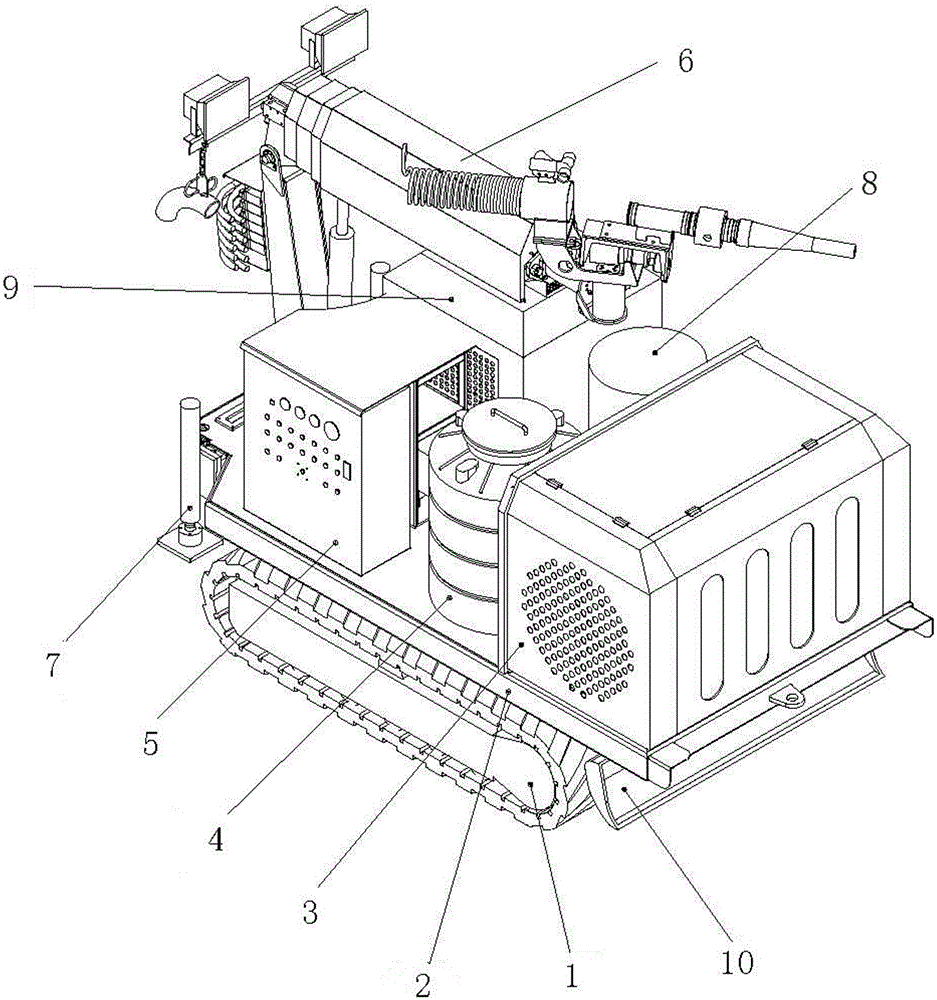

[0023] like figure 1 As shown, the present invention is a concrete spraying manipulator, which only has the function of concrete spraying, but does not have the function of concrete pumping, that is, the equipment of the present invention does not have a concrete pump. When concrete needs to be transported, the present invention can be combined with concrete pumps, Combined with concrete pump truck, continuous wet spraying operation is carried out after external power supply and external compressed air are connected. If appropriate, users can choose existing concrete delivery pumps for concrete delivery during construction. If the existing concrete delivery pump is not suitable, when purchasing a new concrete delivery pump, the appropriate delivery pump can be selected according to the injection flow required for actual construction, which makes the configuration more reasonable and, of course, more economical.

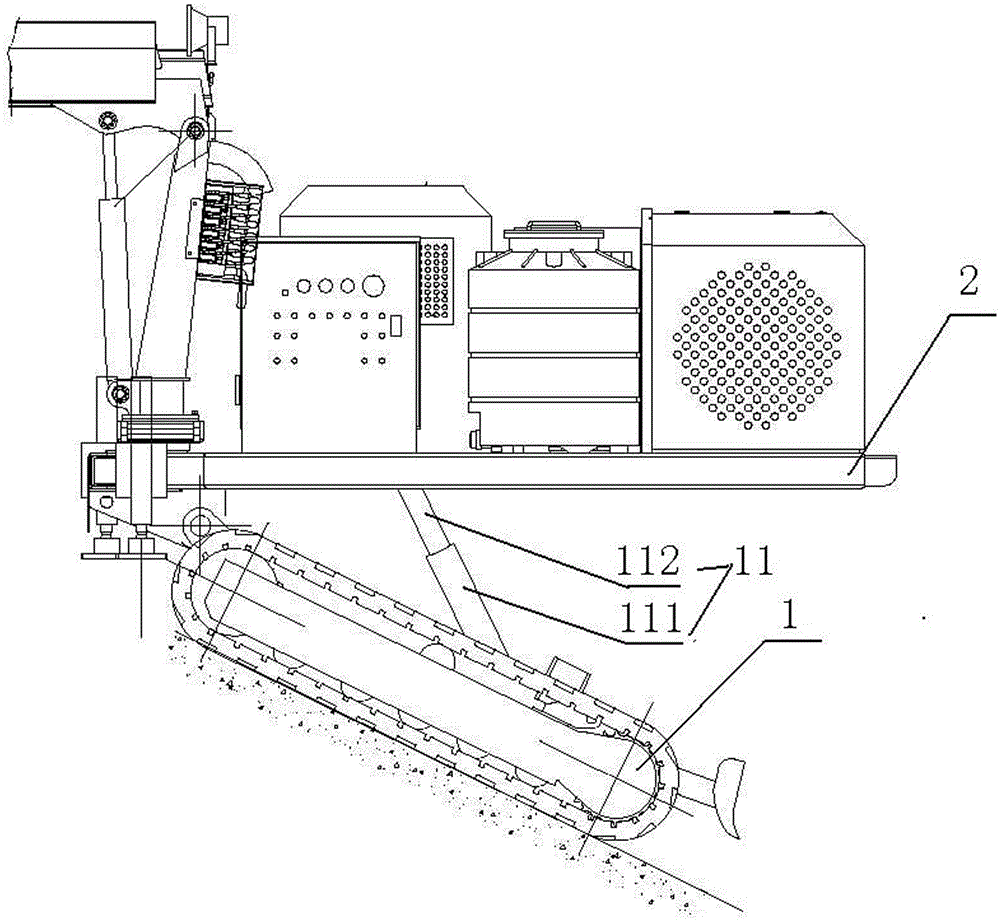

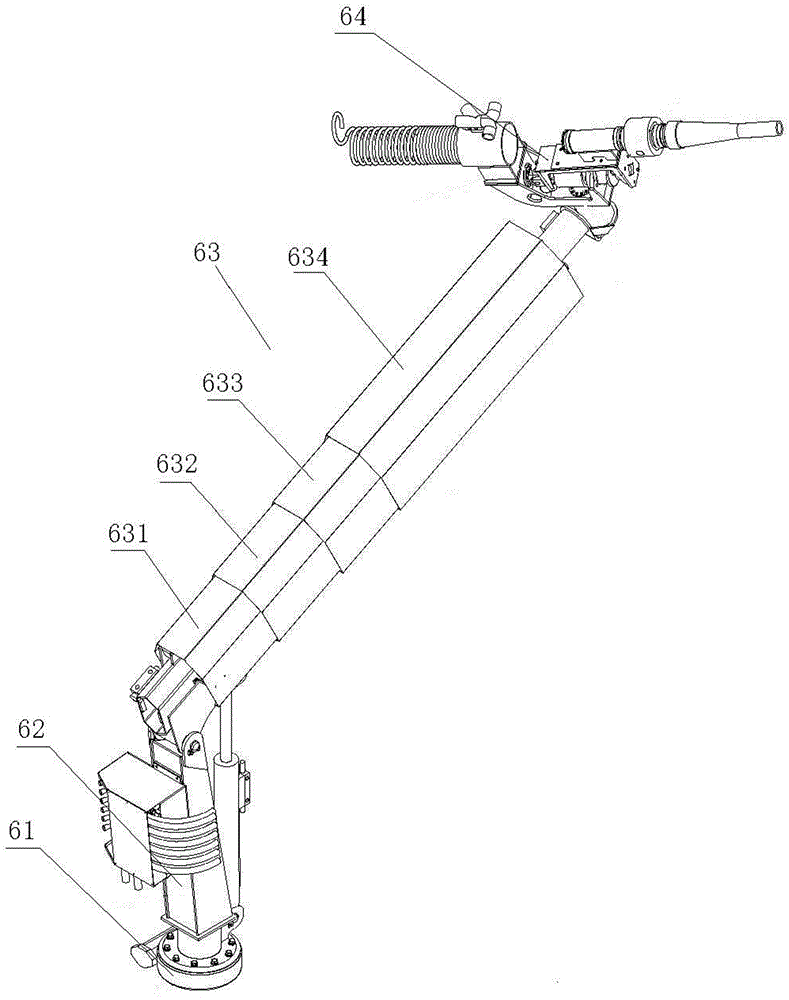

[0024] The concrete injection manipulator of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com