Cultivation soil treatment device for agricultural cotton planting

A processing device and cultivation soil technology, which is applied in the field of cultivation soil processing devices for agricultural cotton planting, can solve the problems of inapplicability to large-scale promotion, troublesome cultivation soil treatment, complicated process, etc., and achieves easy cultivation and transplantation, simple structure, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

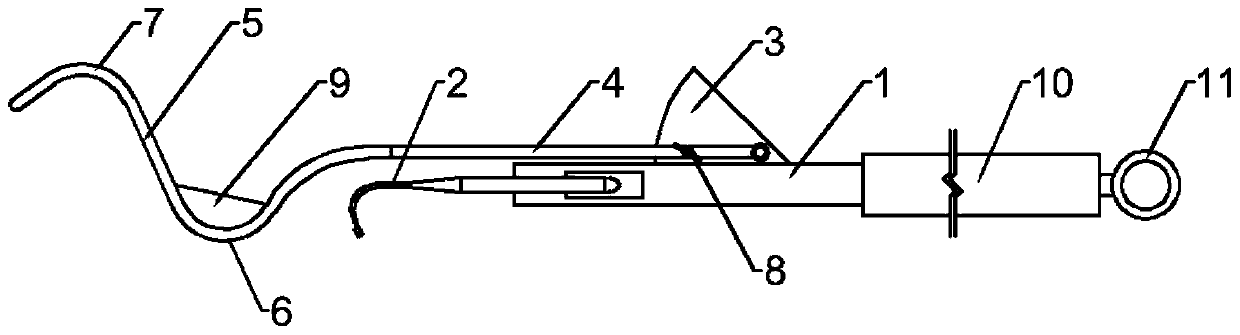

[0023] Example 1: Please refer to Figure 1-3 , a cultivation soil treatment device for agricultural cotton planting, comprising a fixed rod 1, a plurality of scraper teeth 2 are fixedly connected to the left end of the fixed rod 1, and the distance between the scraper teeth 2 is 2-8cm. When in use, the device is held by hand and used The scraping teeth 2 scrape impurities on the cotton cultivation soil, and this process is consistent with the traditional rake removal process;

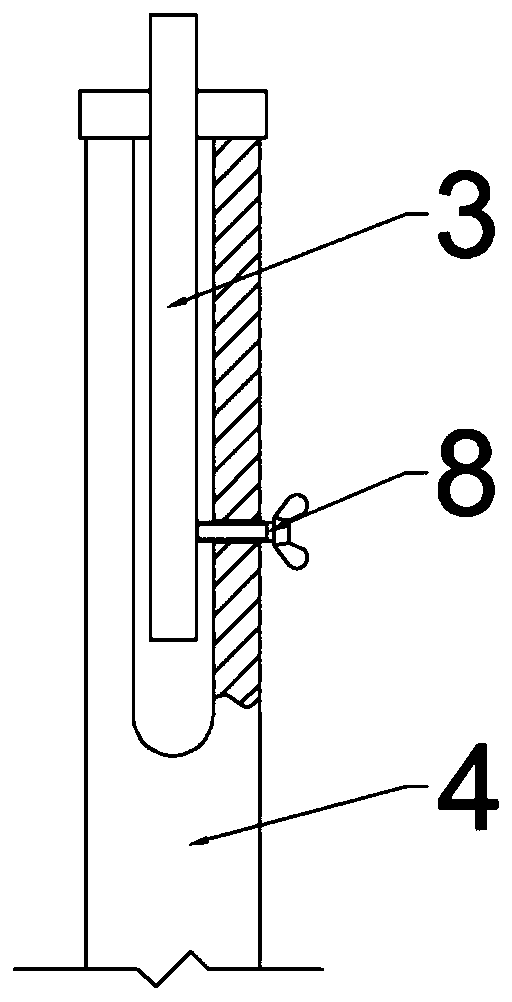

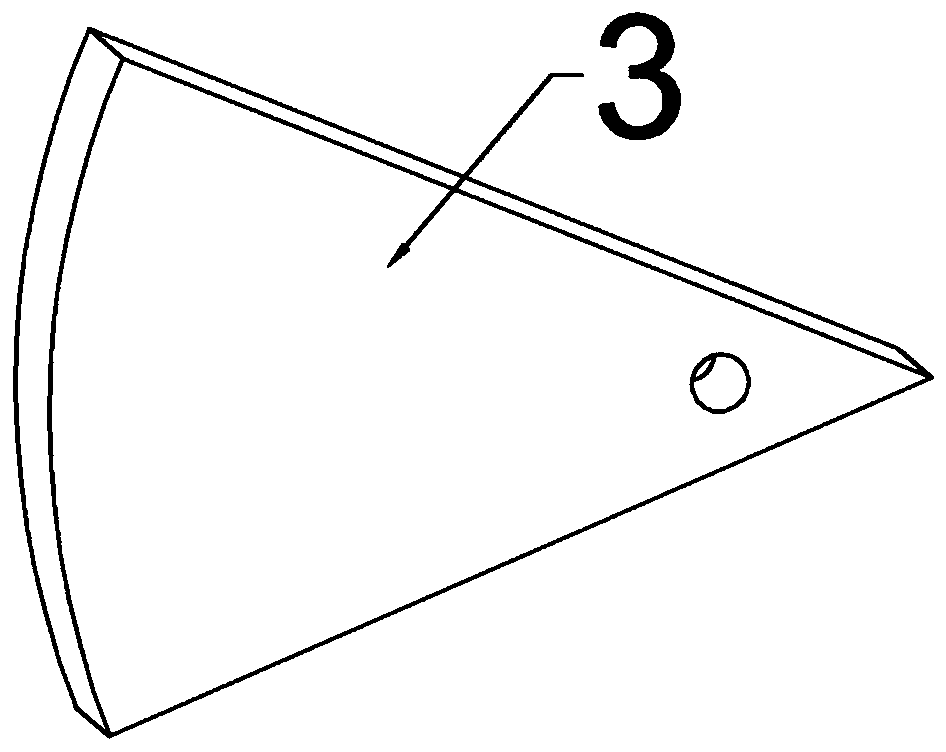

[0024] A fan-shaped vertical plate 3 is fixedly connected to the top of the fixed rod 1, and a swing rod 4 is connected to the outside of the fan-shaped vertical plate 3 for rotation. The left end of the swing rod 4 is fixedly connected to a special-shaped scraper 5. The second scraping part 7, when the fixed rod 1 and the swing rod 4 are in a horizontal state, the first scraping part 6 is located under the scraping teeth 2, the first scraping part 6 is in the shape of a downward arc convex, and the se...

Embodiment 2

[0034] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the front and rear sides of the first scraper 6 are fixedly connected with a side baffle 9, one end surface of the side baffle 9 is in a horizontal state, and the side baffle 9 is the highest The width is 8cm. By arranging side baffles 9 at the end of the first scraper 6, heavy objects can be placed above the first scraper 6, thereby adjusting the downforce of the first scraper 6 during the leveling process. The cultivation soil will be flattened at the flat speed, and the pressurized weight can be selected according to actual needs.

[0035] The working principle of the present invention is: when in use, hold the device by hand and use the scraper teeth 2 to scrape the cotton cultivation soil. This process is consistent with the traditional rake removal process, and the butterfly bolt can be rotated during the removal process. 8, so that the butterfly bolt 8 is disengaged from the fan-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com