Perforated Microsilicon Microphone

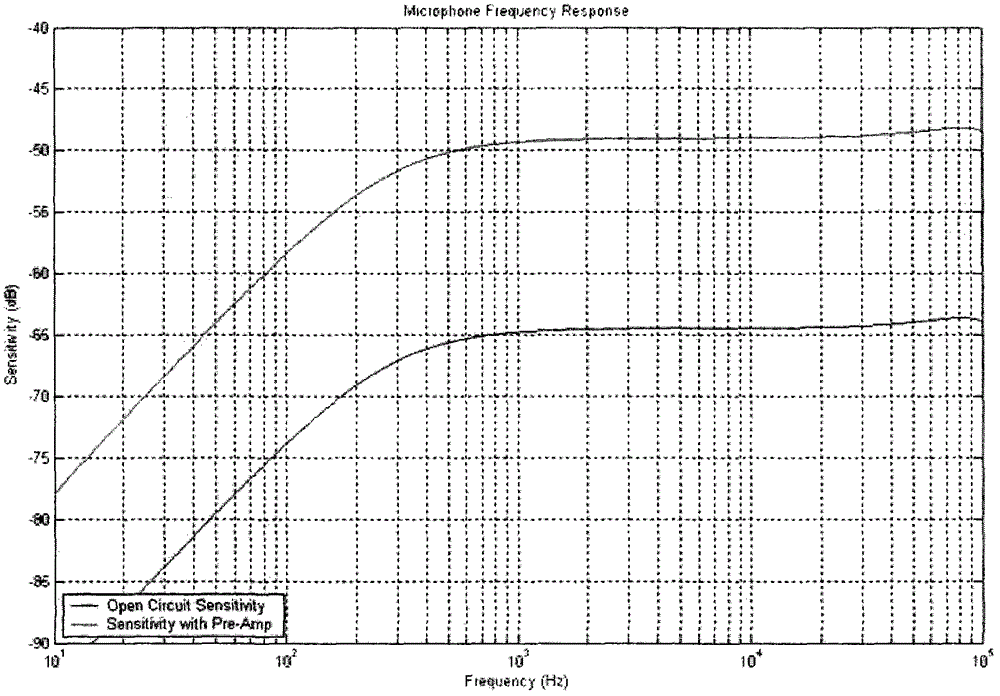

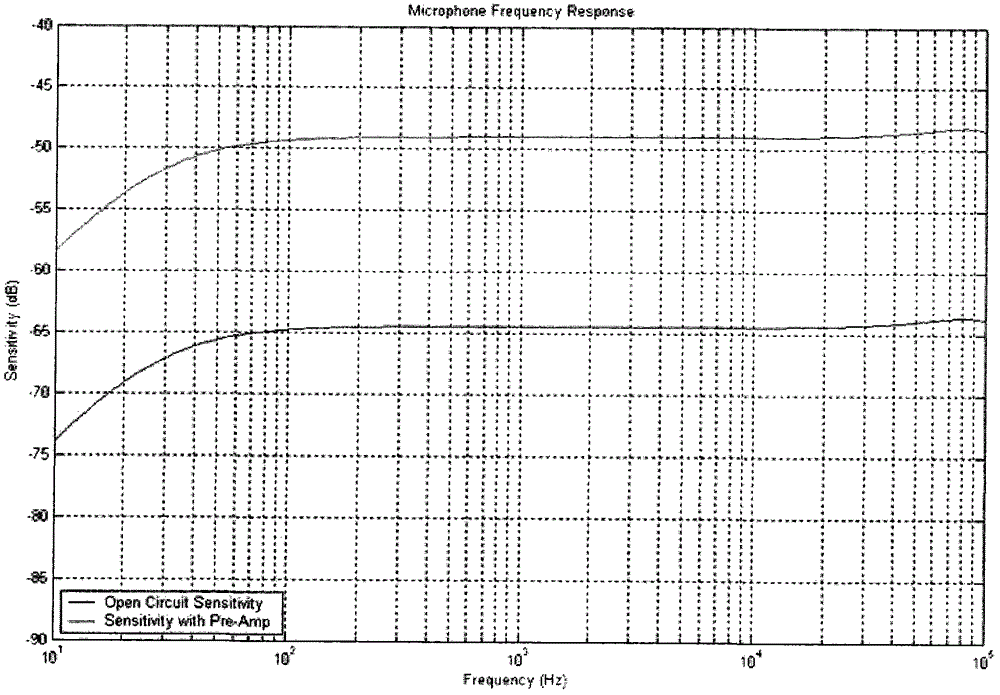

A silicon microphone, miniature technology, used in sensor parts, sensors, electrostatic transducer microphones, etc., can solve the problems of reducing the signal-to-noise ratio of the microphone, reducing the original sensitivity of the microphone, etc., to achieve high signal-to-noise ratio, wide and flat The effect of frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

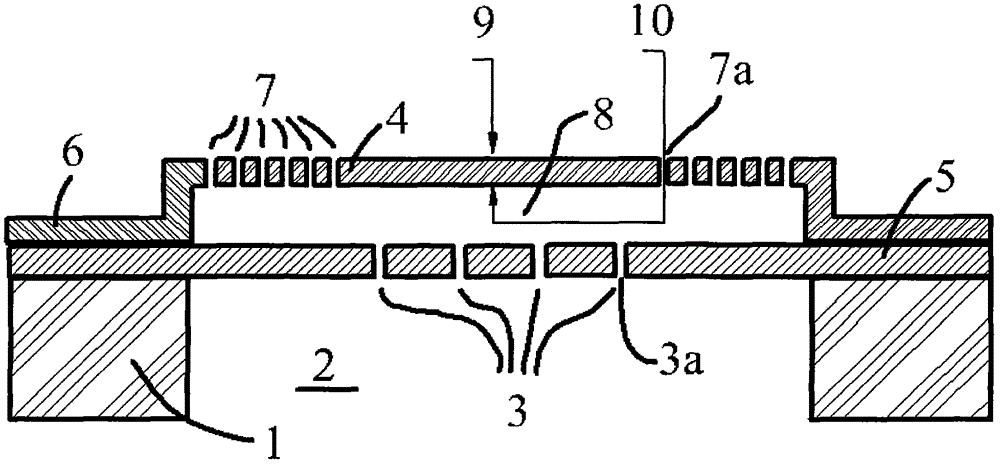

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0039]For a silicon condenser microphone, its sensitivity is mainly related to the control of the internal stress of the diaphragm; when the size of the diaphragm is fixed, its mechanical sensitivity is inversely proportional to the internal stress in the diaphragm. A diaphragm is most mechanically sensitive when free to move like a piston in a plane perpendicular to its own plane. On the other hand, a certain degree of internal stress needs to be maintained in the diaphragm so that its resonant frequency is far away from the frequency range in which it operates, thus exhibiting a flat frequency response in the audio frequency range. In addition, the separator needs to be made harder from the viewpoint of mechanical strength. This seems to contradict the proposed requirement that silicon condenser microphones need to have a method of tightly controlling their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com