Thin film type microphone array

A microphone array and film-type technology, which is applied in the field of microphones, can solve the problems that the volume of the device cannot be reduced and the cost performance needs to be improved, and achieve the effects of simple manufacturing process, light weight and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

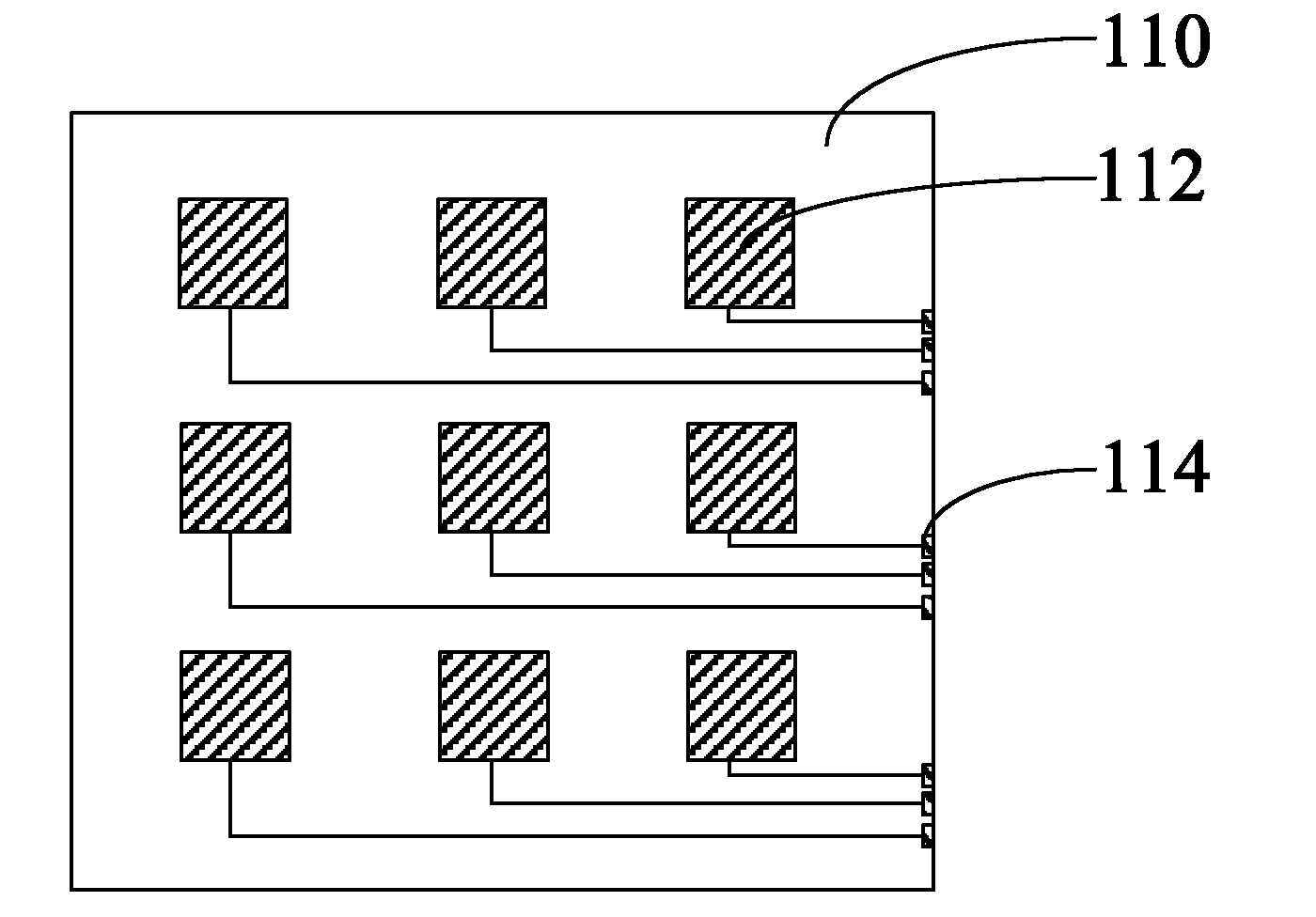

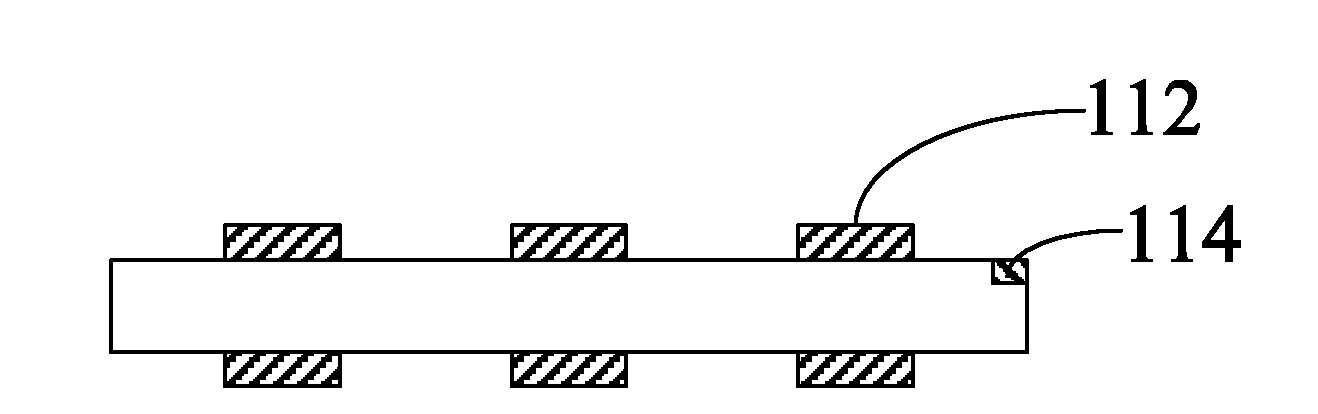

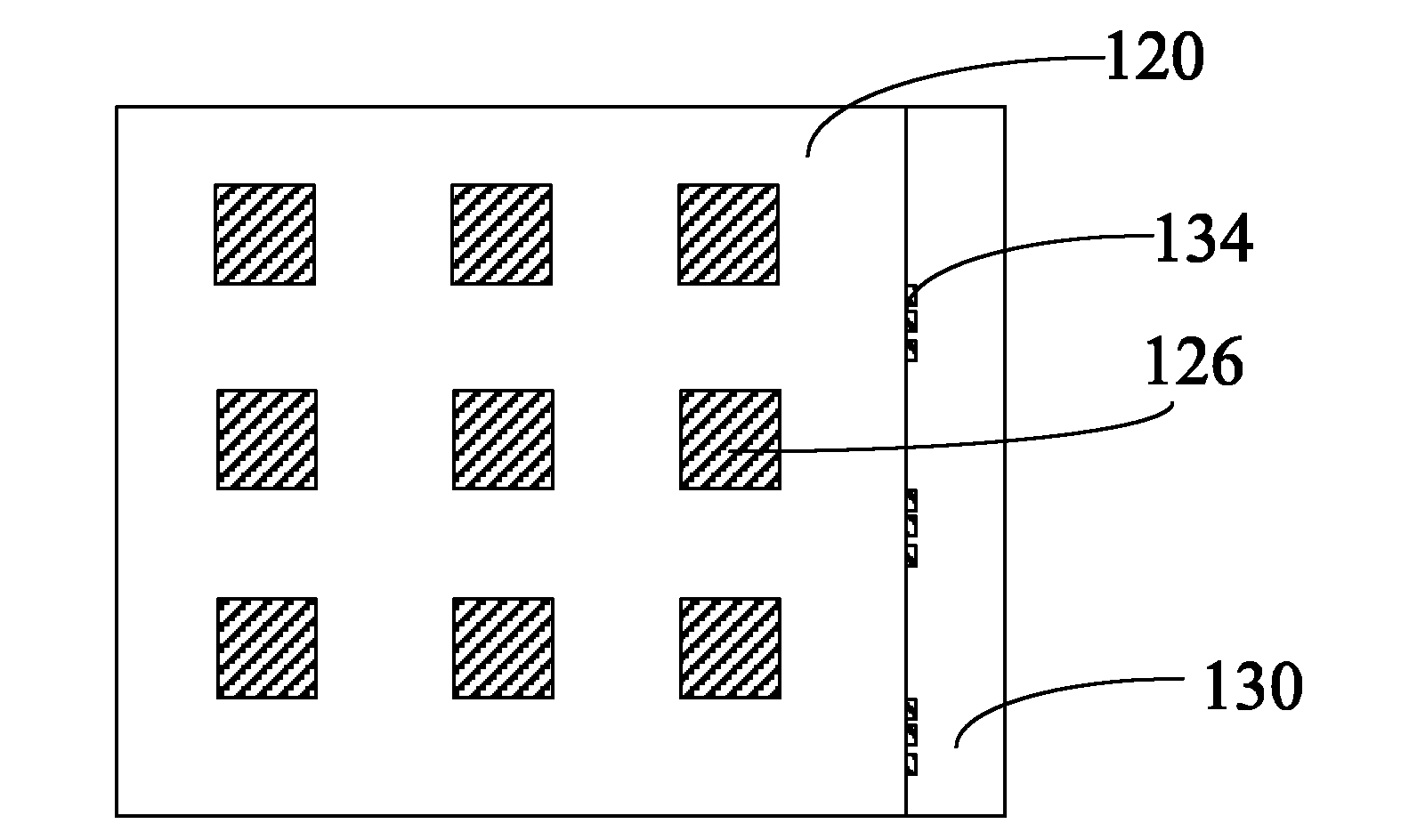

[0027] Please combine Figure 1-Figure 4 , the film-type microphone array in this embodiment includes a piezoelectric electret film 110 , a circuit board assembly 120 and a connector 130 .

[0028] The piezoelectric electret film 110 is a porous polymer film with a thickness ranging from tens to hundreds of microns. Such as figure 1 and figure 2 As shown, the piezoelectric electret film 110 in this embodiment is square, and 3×3 block electrodes are correspondingly arranged on both sides to form an electrode array 112 . Each pair of bulk electrodes corresponding to both sides and the piezoelectric electret film between them jointly form a piezoelectric microphone unit. This embodiment includes 9 piezoelectric microphone units. The piezoelectric electret film 110 is provided with an electrode connection terminal 114 at the edge that is electrically connected to each bulk electrode on one side.

[0029] The porous polymer film deposits positive and negative charges on the u...

Embodiment 2

[0038] Such as Figure 6 and Figure 7 As shown, the film-type microphone array of this embodiment includes a piezoelectric electret film 210 and a circuit board assembly 220 .

[0039] The piezoelectric electret film 210 is a porous polymer film with a thickness ranging from tens to hundreds of microns. The piezoelectric electret film 210 in this embodiment is square, and 3×3 block electrodes are correspondingly arranged on both sides to form an electrode array 212 . Each pair of bulk electrodes corresponding to both sides and the piezoelectric electret film between them jointly form a microphone unit. This embodiment includes 9 microphone units. The piezoelectric electret film 210 is provided with a first electrode connection end 214 and a second electrode connection end 216 at the edge, which are electrically connected to the electrodes on both sides.

[0040] The circuit board assembly 220 of this embodiment is fixed on the blank area of the piezoelectric electret fi...

Embodiment 3

[0043] Such as Figure 8 and Figure 9 As shown, the film-type microphone array of this embodiment includes a piezoelectric electret film 310 , a circuit board assembly 320 and a connector 330 .

[0044] The piezoelectric electret film 310 is a porous polymer film with a thickness ranging from tens to hundreds of microns. The piezoelectric electret film 310 in this embodiment is square, and 3×3 block electrodes are correspondingly arranged on both sides to form an electrode array 312 . Each pair of bulk electrodes corresponding to both sides and the piezoelectric electret film between them jointly form a microphone unit. This embodiment includes 9 microphone units. The piezoelectric electret film 310 is provided with a first electrode connection end 314 and a second electrode connection end 316 at the edge, which are electrically connected to the electrodes on both sides.

[0045] The circuit board assembly 320 is provided with a microphone circuit (not shown in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com