Method for improving piezoelectric response of polymer materials

A technology of polymer materials and polymer films, applied in applications, flat products, household appliances, etc., to achieve the effect of small modulus, low density, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

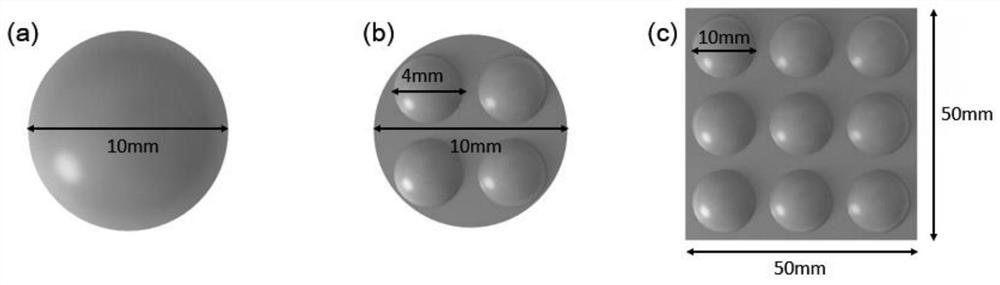

[0041] The present invention has no special limitation on the preparation method of the polymer film, and any method known to those skilled in the art will suffice. In the present invention, a flat polymer film can be prepared by a film casting process, and then the film can be prepared into an arched structure with a certain radius of curvature or a triangular structure with different heights under a certain temperature and pressure using a mold. In the present invention, either one non-planar structure or multiple non-planar structures can be produced.

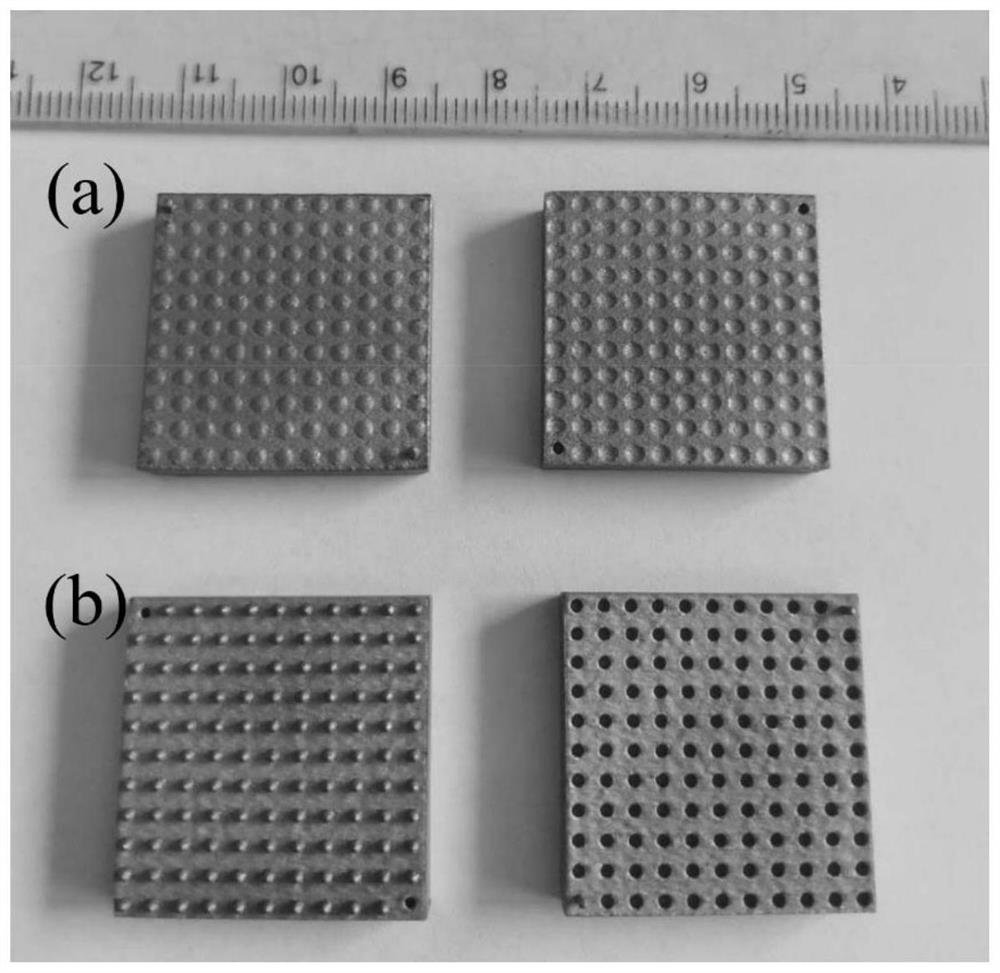

[0042] see image 3 , image 3 Photographs of molds for the preparation of non-planar polymer films provided for the present invention. Wherein, when preparing a non-planar polymer film, the polymer film material is cast into a mold, and the two parts of the mold are extruded to obtain a non-planar polymer film.

[0043] exist image 3 Among them, the mold provided by (a) can be prepared to obtain a polymer film with mul...

Embodiment 1

[0063] Dissolve P(VDF-TrFE) powders of different masses (0.3g, 0.56g, 0.95g) in a certain volume (10mL) of dimethylformamide solvent, and stir until a clear and transparent liquid is obtained, where the polymer can be controlled The mass-to-volume ratio of powder and solvent prepares a series of films with different thicknesses (wherein, a solution with a concentration of 0.3g / 10mL prepares a film with a thickness of 23 μm, a solution with a concentration of 0.56g / 10mL prepares a film with a thickness of 43 μm, and a solution with a concentration of 0.95g / 10mL solution to prepare a thin film with a thickness of 73 μm). The solution was poured on a glass plate in an oven and evaporated to dryness at 90°C. The evaporated film was peeled off from the glass and either used directly or subjected to heat treatment at 140 °C for 5 hours to obtain higher crystallinity. The resulting film can be cut into different sizes with a knife as required. Put the film into the mold, place the ...

Embodiment 2

[0069] According to the preparation method in Example 1, a polymer flat film with a thickness of 23 μm was obtained. Pass the above film through a mold to prepare an arched film with a radius of curvature of 10 mm.

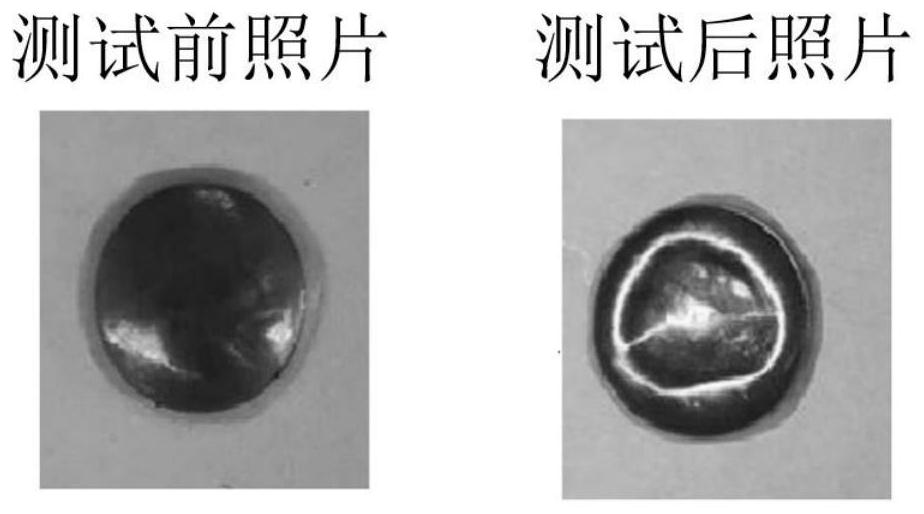

[0070] In order to test the electrical properties, gold electrodes were prepared on the upper and lower sides of the film, and the film was polarized under DC voltage before the test. According to the polarization conditions (polarization electric field, temperature and time) given in Table 2, the polymer The film is polarized, and according to Figure 4 test method for testing.

[0071] On the upper and lower sides of the arched membrane, the upper and lower surface forces are applied to the membrane by two flat metal hard plates, so that the arched membrane has a wrinkled structure and stress concentration. The obtained piezoelectric responses of the arched film under different polarization conditions are shown in Table 2. It can be seen that the greater the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com