Guidewire

A wire and coil technology applied to wires. Field, can solve problems such as residue, coil falling off, coil spring falling off, etc., to achieve the effect of improving the strength of fixed connection, firmly fixed connection, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

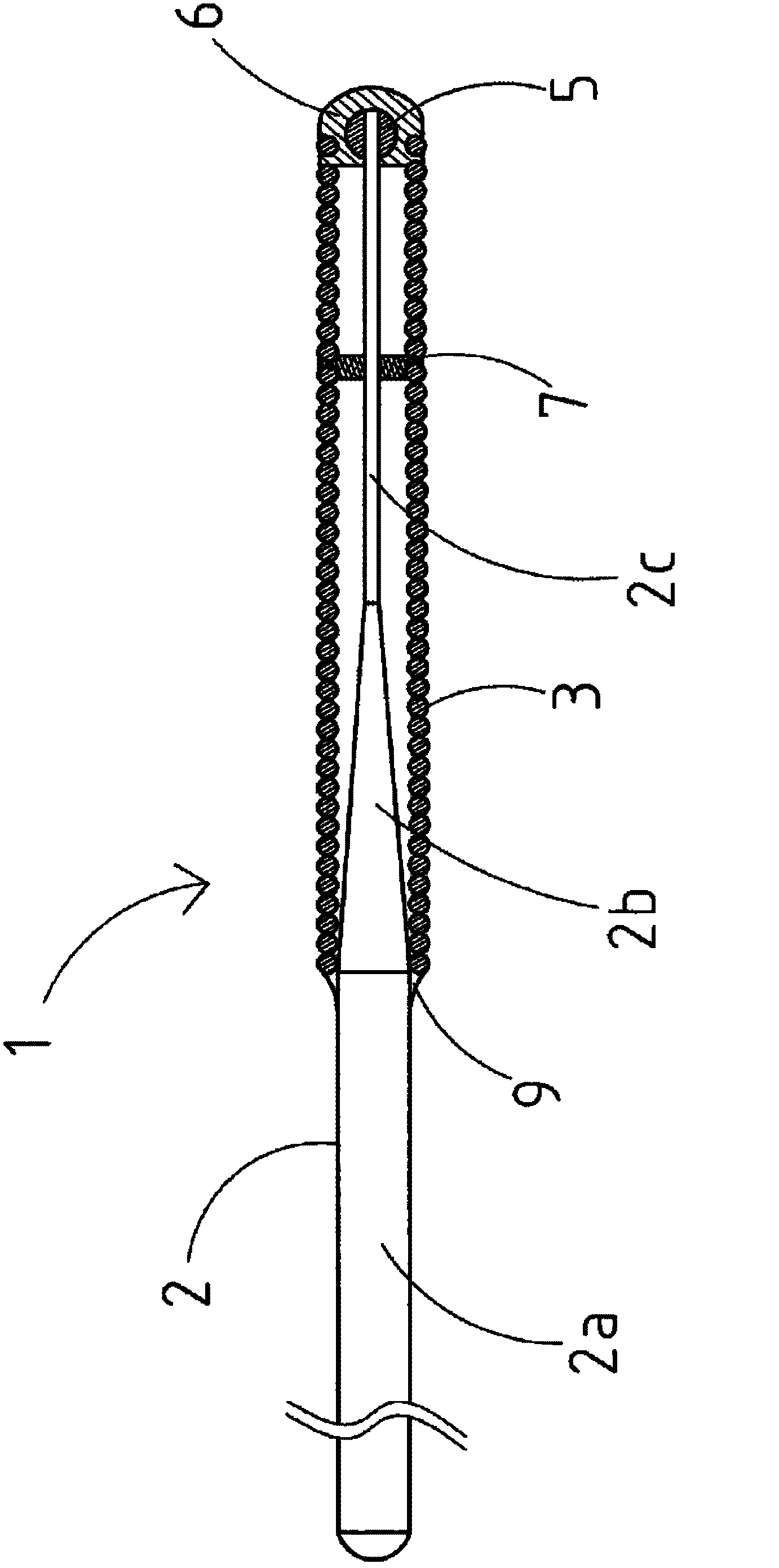

[0050] figure 1 It is an overall view showing the lead wire according to the first embodiment of the present invention.

[0051] For convenience of explanation, in figure 1 In the description, the left side is referred to as a "base end" and the right side is referred to as a "tip end".

[0052] Furthermore, for ease of understanding, the figure 1 The length direction of the lead wire 1 is shortened, and the overall size of the lead wire 1 is different from the actual one in order to schematically illustrate the whole.

[0053] exist figure 1 Among them, the lead wire 1 includes a mandrel 2 and a coil member 3 covering the front end of the mandrel 2 .

[0054]The mandrel 2 includes a large diameter portion 2a, a tapered portion 2b located at the front end of the large diameter portion 2a and decreasing in outer diameter toward the front end, and a small diameter portion 2c located at the front end of the tapered portion 2b.

[0055] A swollen portion 5 is provided on the ...

no. 2 approach

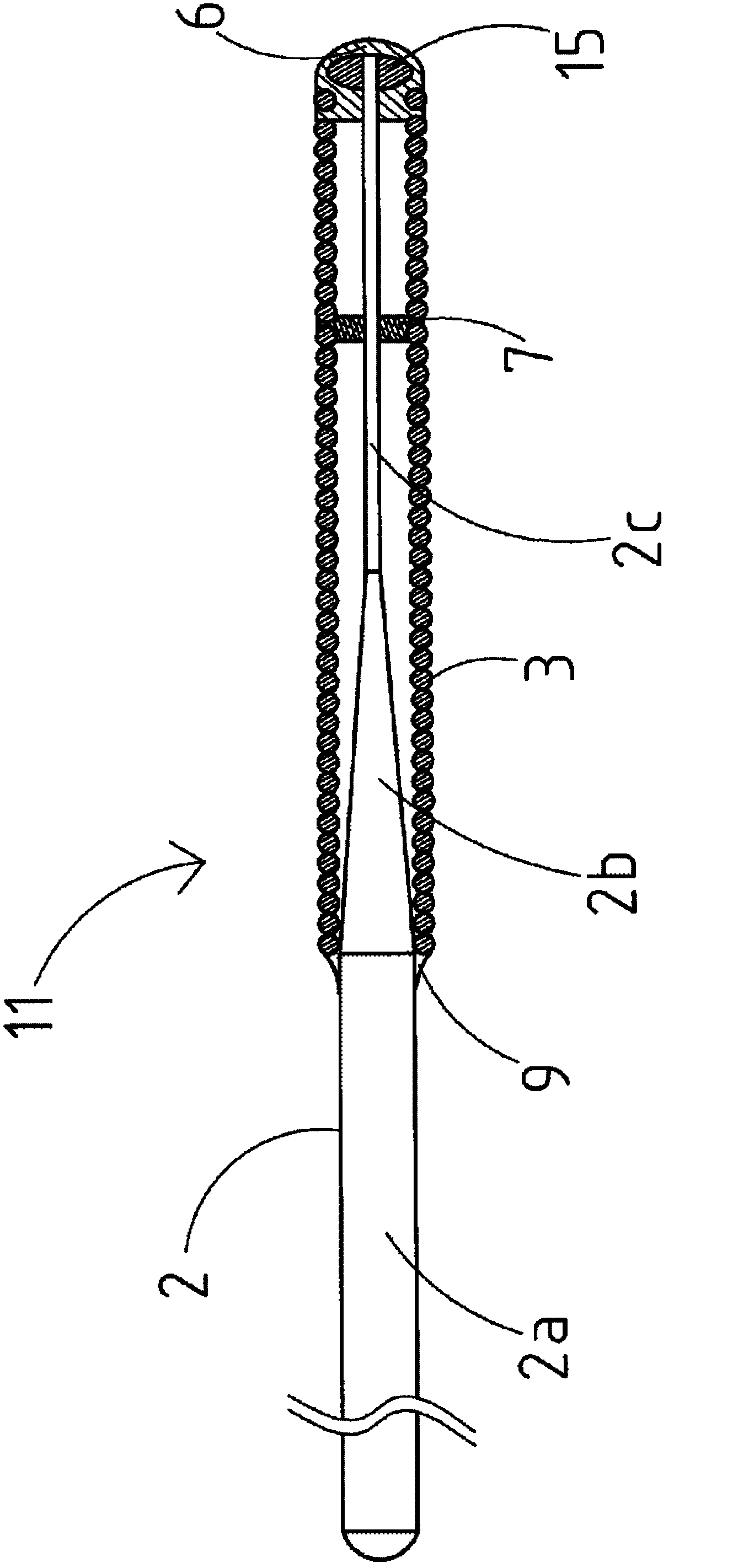

[0098] Next, use figure 2 , the lead wire 11 of the second embodiment will be described focusing on the differences from the first embodiment. In the drawings, the same parts as those of the first embodiment are given the same reference numerals.

[0099] In addition, for ease of understanding, figure 2 Here, the length direction of the lead wire 11 is shortened, and in order to schematically illustrate the entirety of the lead wire 11 , the overall size of the lead wire 11 is different from the actual one.

[0100] exist figure 2 Among them, the wire 11 has the same basic structure as the wire 1 , except that the outer diameter of the bulge 15 is larger than the inner diameter of the coil of the coil member 3 .

[0101] Since the outer diameter of the bulging portion 15 of the lead wire 11 is larger than the coil inner diameter of the coil member 3, the coil member 3 can be further prevented from falling off the mandrel 2, thereby further improving the safety of the lea...

no. 3 approach

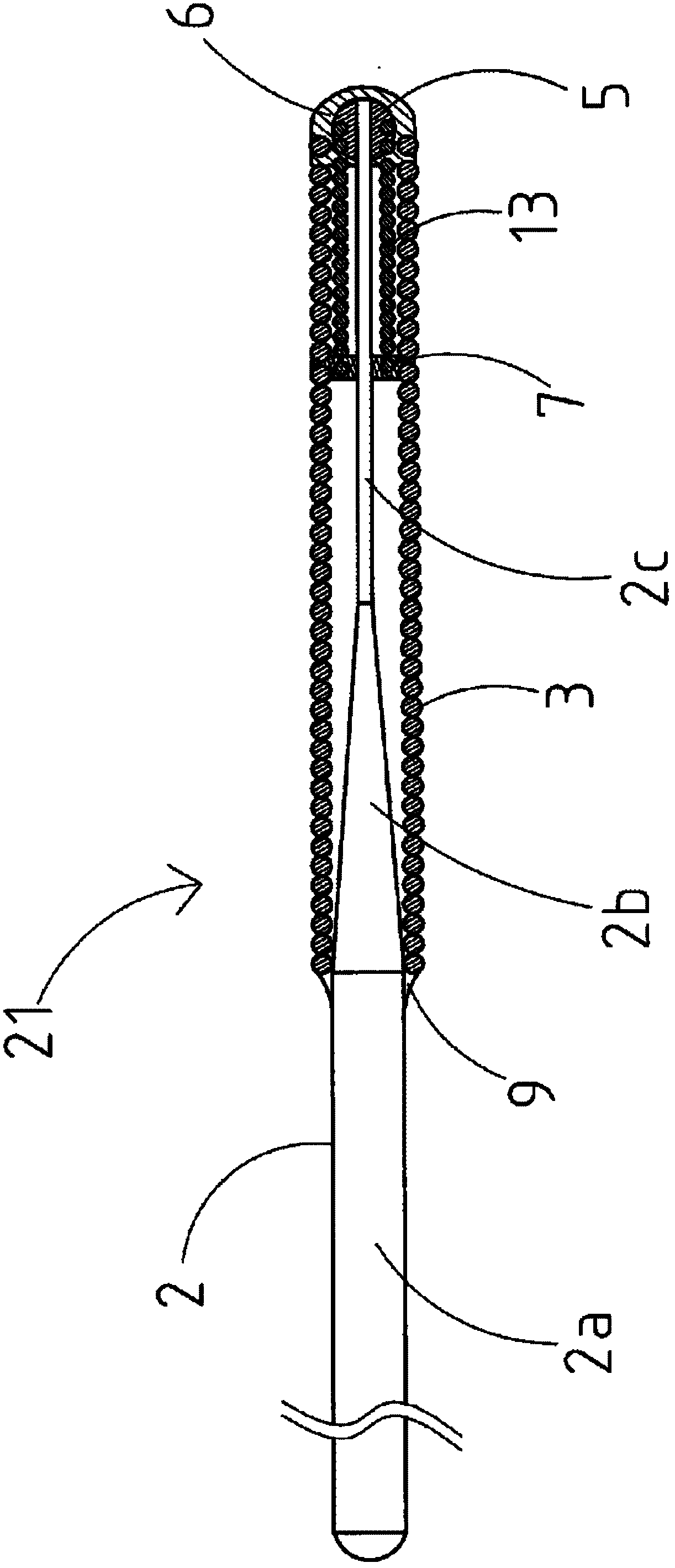

[0105] Next, use image 3 , the lead wire 21 of the third embodiment will be described focusing on the differences from the first embodiment. In the drawings, the same parts as those of the first embodiment are given the same reference numerals.

[0106] In addition, for ease of understanding, image 3 The length direction of the lead wire 21 is shortened, and in order to schematically illustrate the entirety of the lead wire 21, the overall size of the lead wire 21 is different from the actual one.

[0107] exist image 3 Among them, the lead wire 21 includes: a mandrel 2; a coil member 3 covering the front end of the mandrel 2; The distal end of the small-diameter portion 2c of The front end of the coil member 3 is fixedly connected to the front end of the mandrel 2 and the front end of the inner coil member 13 through the fixed connection portion 6 so that the fixed connection portion 6 covers the bulge portion 5 . Further, the proximal end of the coil member 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com