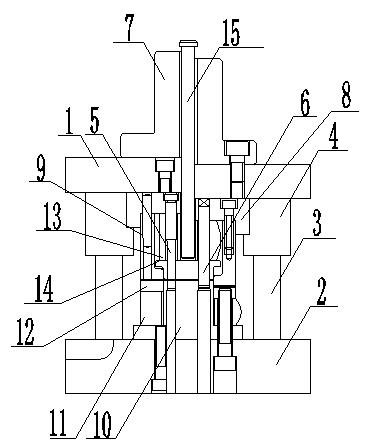

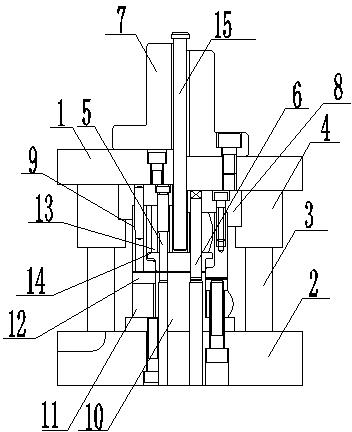

Sheet-shaped plates compound die

A composite mold and plate technology, applied in the field of composite molds, can solve problems such as low positioning accuracy, low safety in use, and high labor intensity, and achieve the effects of reducing labor intensity, improving quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] When processing the connecting piece, the upper mold base 1 is connected and positioned with the punch press through the mold handle 7, the lower mold base 2 is installed on the working table of the punch press, the supporting plate 12 and the supporting material rubber 11 support the connecting piece, and the upper mold 9 When working with the lower die body 10, the guide post 3 and the guide sleeve 4 are guided up and down, thereby cutting the shape of the connecting piece. The inner elliptical hole of the sheet, after completion, the connecting sheet completed by punching and shearing is taken out by the cooperation of the discharge rubber 13, the discharge plate 14 and the shoulder push rod 15.

Embodiment 2

[0017] When processing the stop gasket, the upper mold base 1 is connected to the punch press through the handle 7 for positioning, the lower mold base 2 is installed on the working table of the punch press, and the support plate 12 and the support rubber 11 support the stop gasket , when the upper mold 9 and the lower mold body 10 are working, the guide post 3 and the guide sleeve 4 are guided up and down, thereby cutting the shape of the stop gasket, and at the same time, the first punch 5 and the second punch 6 punch the stop Two identical inner circular holes of the gasket are completed by the discharge rubber 13, the discharge plate 14 and the shoulder push rod 15 to cooperate to take out the stop gasket completed by punching and shearing.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap