Welding positioner with heating temperature control device

A technology of welding positioner and temperature control device, which is applied in the field of machinery to increase the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

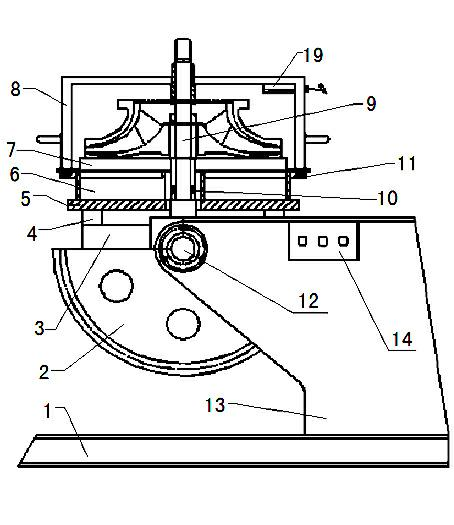

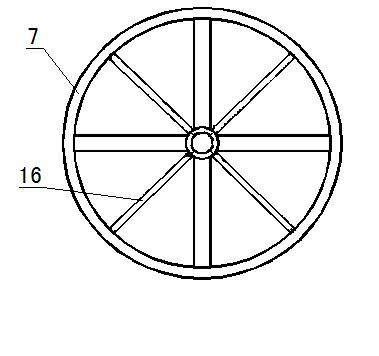

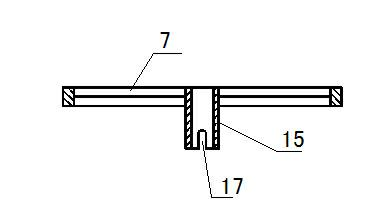

[0019] Such as figure 1 , 2 , 3, 4, 5, and 6, a welding positioner with a heating temperature control device, including a base 1, two brackets 13 installed on the base 1, and a half shaft 12 arranged on the bracket 13, installed The half-circle bull gear 2 meshing with the reducer gear between the half-shafts 12, said semi-circle bull gear 2 is fixedly installed with a reduction box 3, and above the reduction box 3 is fixedly installed a heating device tray 5, and above the heating device tray 5 A disc-shaped heating device 6 is fixedly installed, and a hole is opened in the center of the disc-shaped heating device 6, and a main shaft 9 meshing with a gear in the reduction box 3 is installed in the hole, and the main shaft 9 is movable between the disc-shaped heating device 6 There is a rotary table 7, and a heat preservation cover 8 with a gap is fixedly installed on the outside of the rotary table 7, and a thermocouple 19 is arranged inside the heat preservation cover 8; A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com