Unvulcanized tire retaining device

A holding device, unvulcanized technology, applied in tires, packaging, transportation and packaging, etc., can solve problems such as breakage, adhesion, and blockage of polyethylene sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

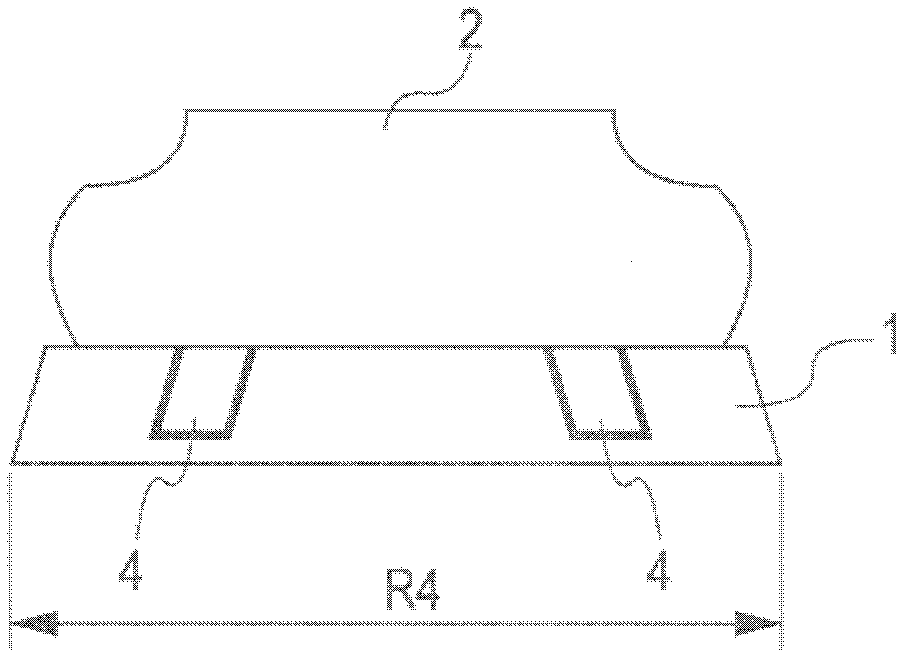

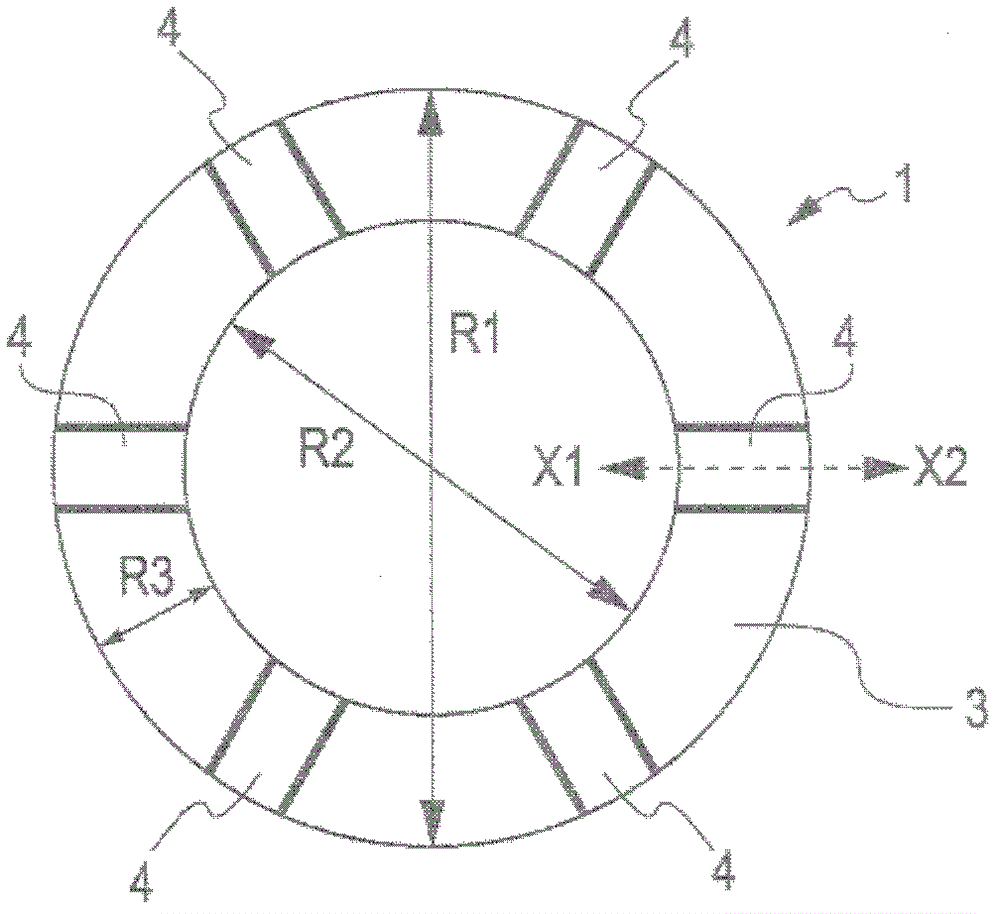

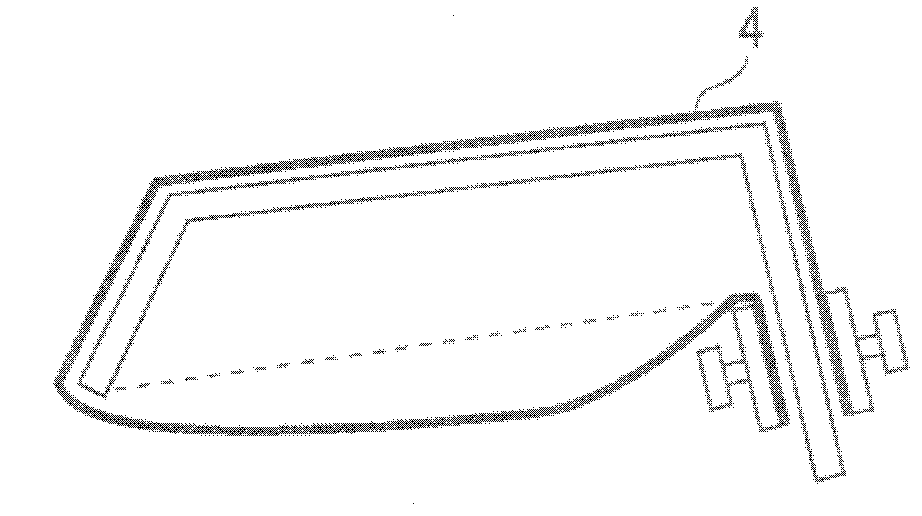

[0061] Next, an exemplary tire holding device of an embodiment of the present invention will be described. The exemplary holding device is Figure 1A An example of a holding device 1 is shown. In these examples, the holding device 1 is made of FRP (Fiber Reinforced Plastic), an epoxy resin mixed with glass fibers. In the holding device 1, the tire holding portion 3—the area for receiving the unvulcanized tire 2—has an outer diameter R1 of 670 mm and an inner diameter R2 of 540 mm (see Figure 1B ).

[0062] Therefore, the tire holding portion 3 has a radial length R3 of 65 mm. The outer shape R4 of the base surface of the holding device 1 (see Figure 1A ) is 730mm. These dimensions are measured in a state where the covering material 4 is not installed.

[0063] These embodiments and the 3 conventional examples as shown in Table 1 were obtained by using holding means with these dimensions and materials and by changing the material of the covering material 4 and the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com