A method for scribing a brittle material substrate

A technology for brittle material substrates and scoring lines, applied in stone processing tools, stone processing equipment, fine working devices, etc., can solve problems such as difficult-to-scratch grooves, glass substrates that cannot be used for scoring, and resin layer tearing. To achieve the effect of simplifying the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

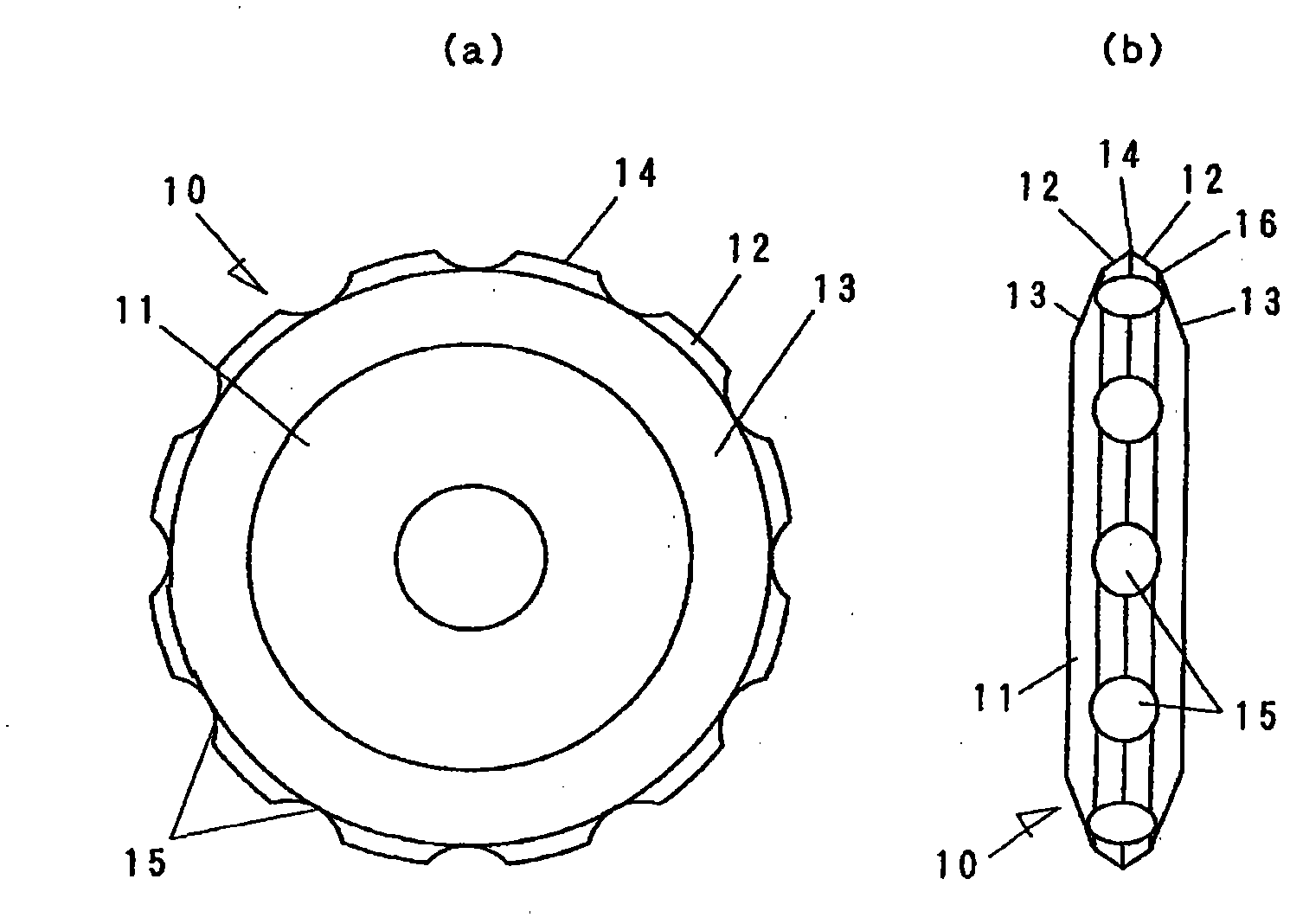

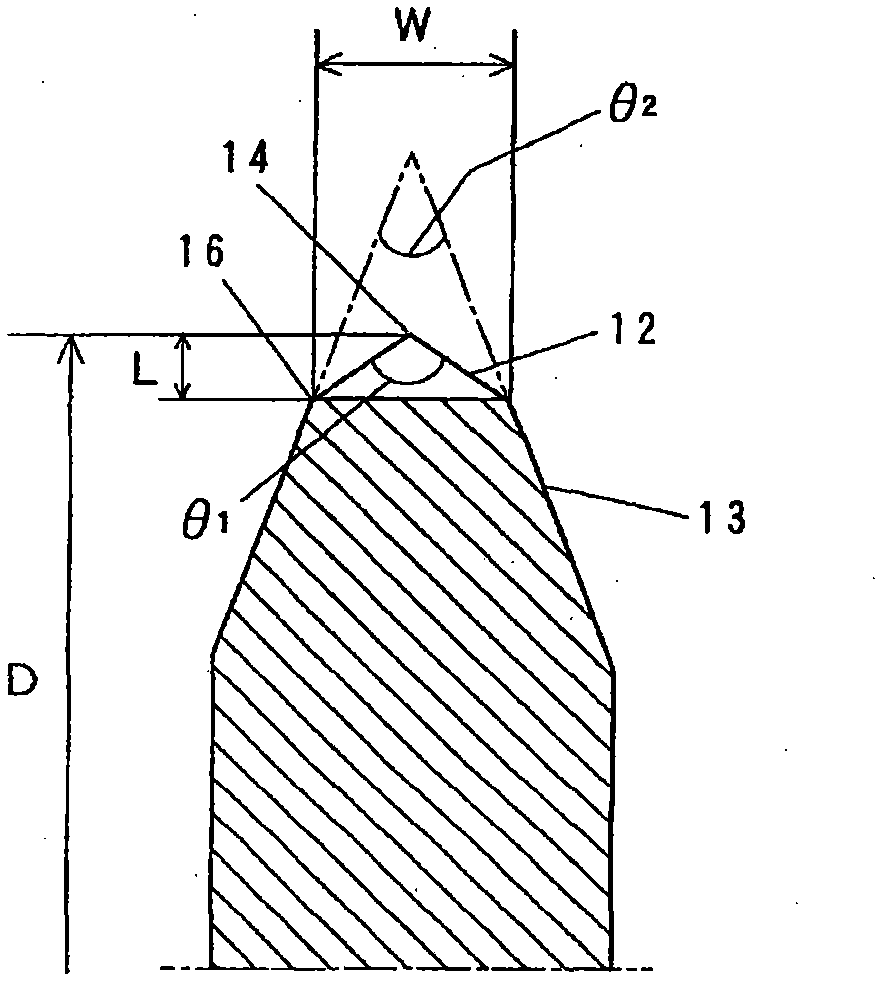

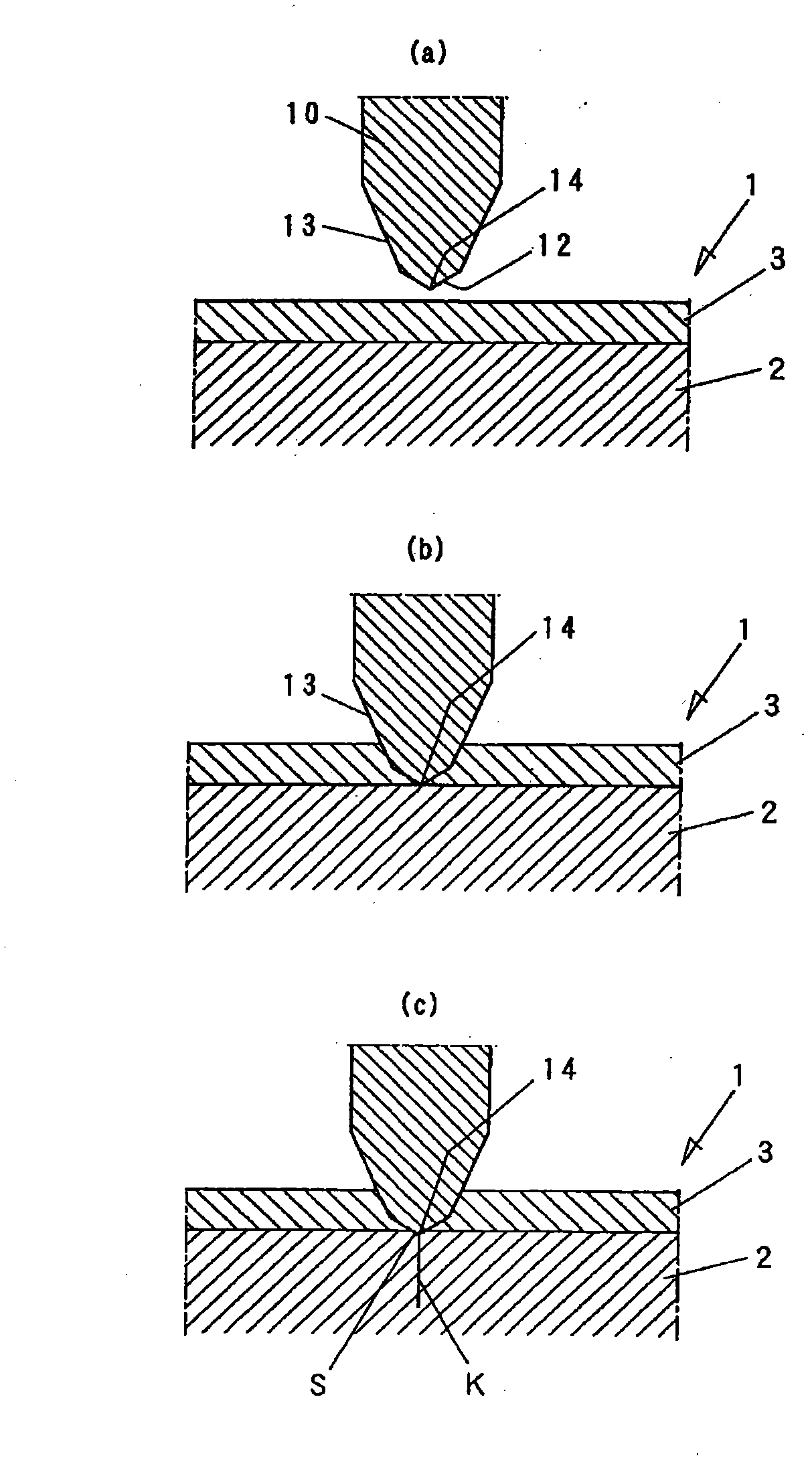

[0040] Hereinafter, the scribing method of the glass plate of the present invention will be described in detail based on the drawings.

[0041] Here, as the substrate for scribing in the present invention, a thick colored glass plate for building materials having a resin layer on the surface will be described as an object. This colored glass plate 1, such as image 3 As shown, a thin resin layer 3 having a thickness of approximately 0.1 mm (as long as it is 0.05 mm to 0.2 mm) is provided on a glass material 2 having a thickness of 4 to 15 mm. The resin layer 3 includes a coating layer for imparting color or a protective resin film attached to it.

[0042] In addition, although horizontal cracks on the surface of the substrate for building materials are a problem, since the plate thickness is thick, the end face can be polished after being broken, so there is no need to care too much about the end face strength. Therefore, the difference in the end face strength required for the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com