Regulation structure of swing arm and swing center for controlling stroke of sewing machine

A technology for controlling the stroke and adjusting the structure, which is applied in the direction of sewing machine components, cloth pressing mechanism, sewing equipment, etc., can solve problems such as unsatisfactory, unadjustable structure, uncertainty of presser foot stroke, etc., and achieve simple, convenient and fast assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

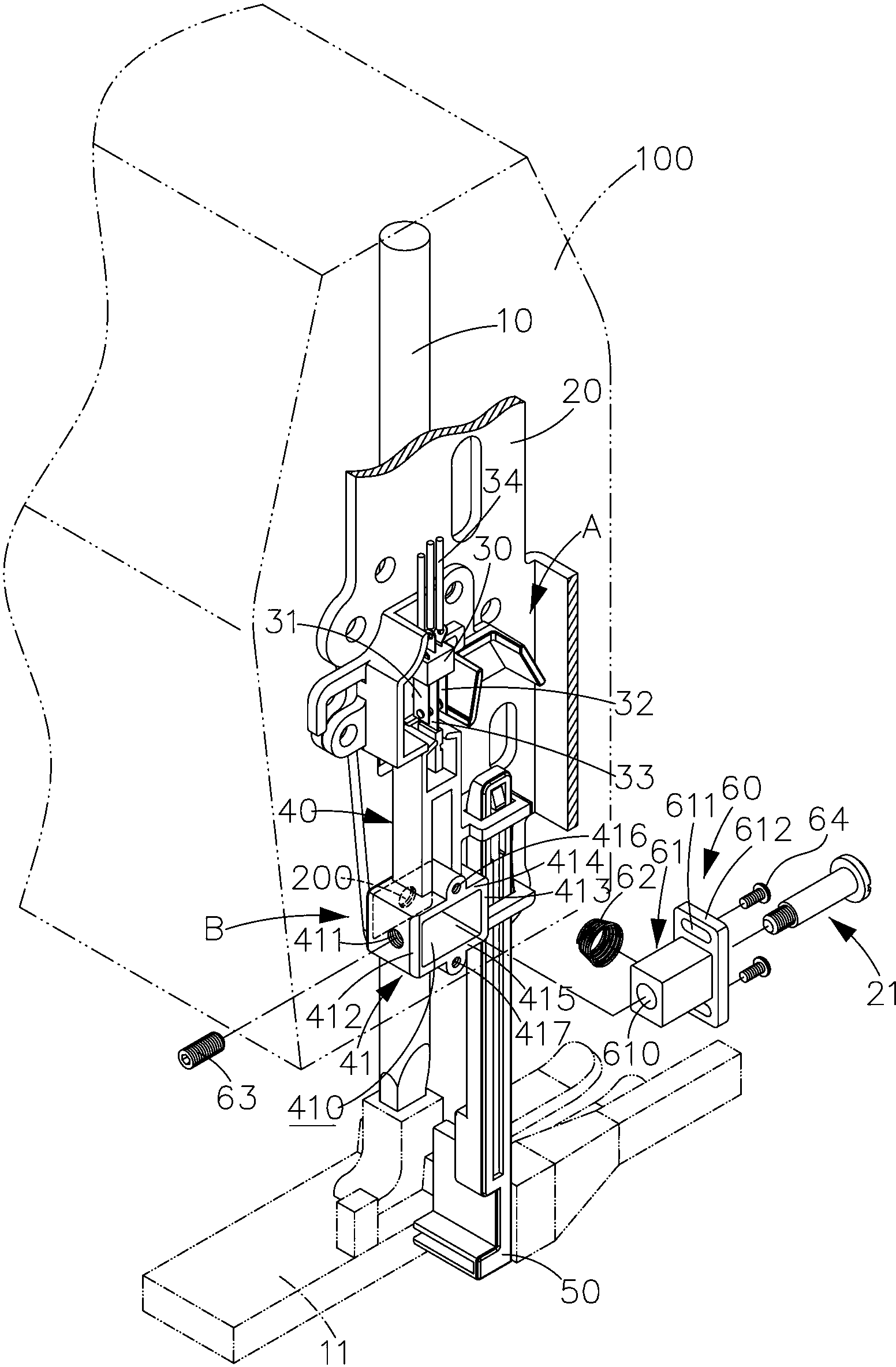

[0055] For the present invention to achieve the above-mentioned purpose, the technology, means and other effects adopted, hereby give a preferred feasible embodiment and cooperate with the drawings in detail as follows, believe that the above-mentioned purpose of the present invention, features and other advantages, should be obtained by it For an in-depth and specific understanding, the present invention is not the only embodiment, so please describe it here.

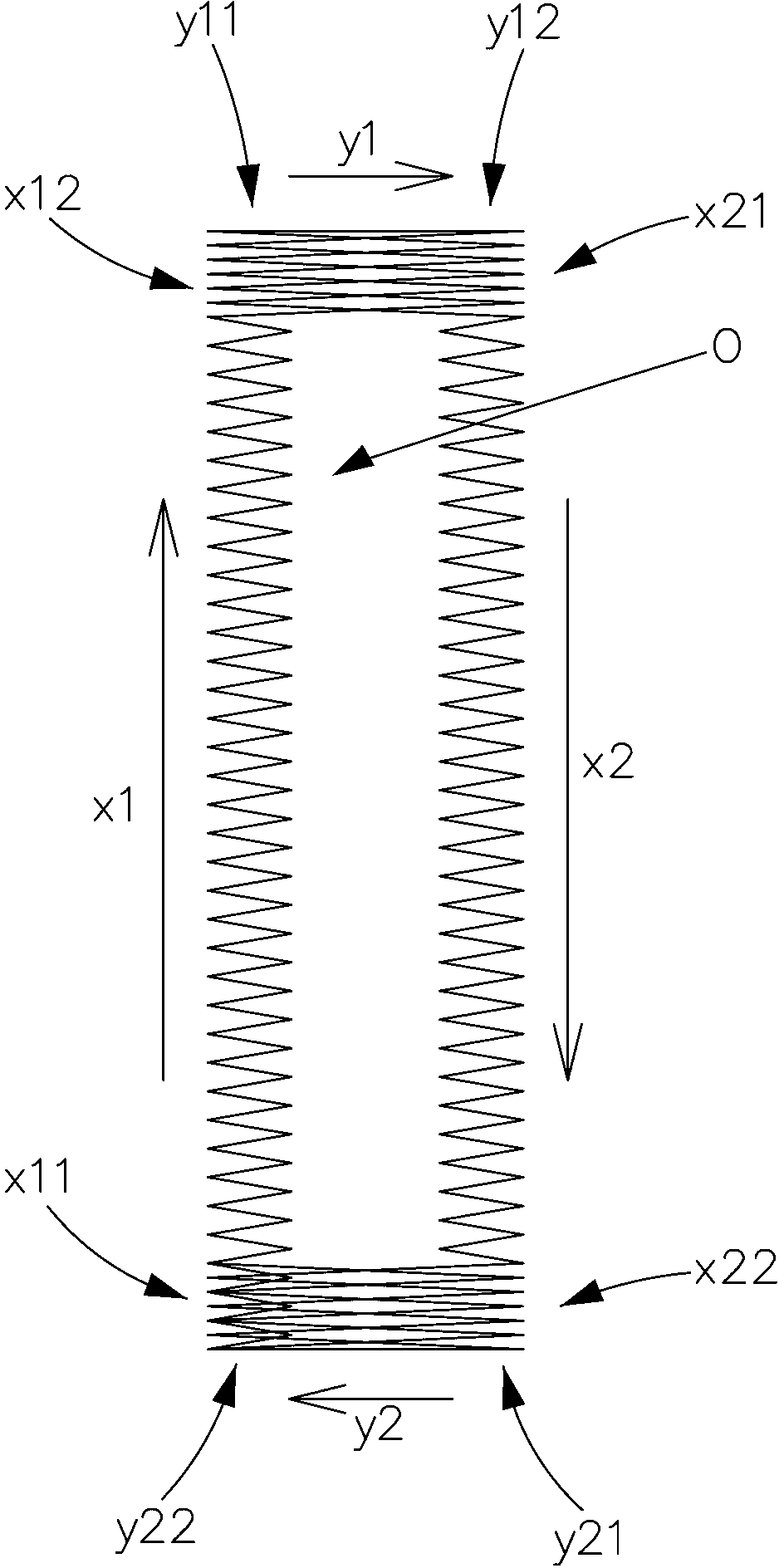

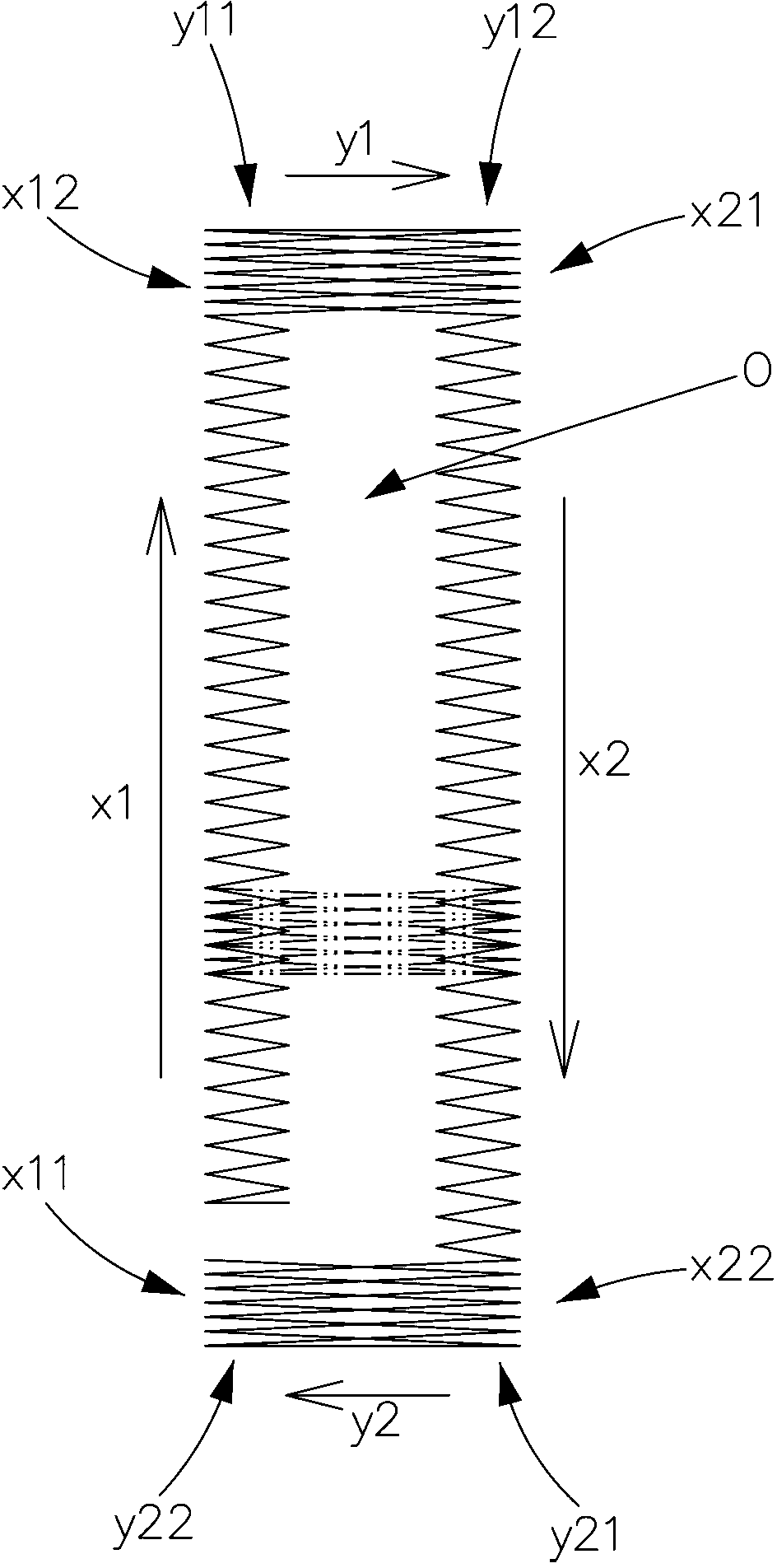

[0056] The structure of the present invention is shown in Fig. 2- Figure 5 As shown, a fixed frame 20 bent from a plate-shaped structure is provided at the free end of the sewing machine cantilever 100 near the presser foot rod 10, and a stroke sensing device A is provided on the fixed frame 20. The stroke sensing device A It includes a sensor 30, a swing arm group B that changes its position with the movement of the presser foot 11 provided at the bottom of the presser foot bar 10, and the swing arm group B has a sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com