Virtual three-dimensional (3D) linkage display dispatching system for coal mining face

A dispatching system and working face technology, applied in mining equipment, mine roof support, earthwork drilling, etc., can solve the problems of small viewing angle, difficult working face dispatching, poor camera adaptability, etc., to achieve wide viewing angle, good depth of field, and improved The effect of dispatch command ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

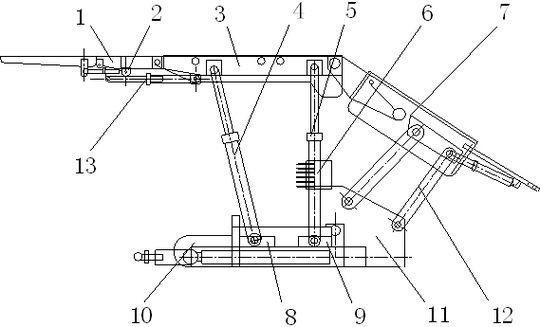

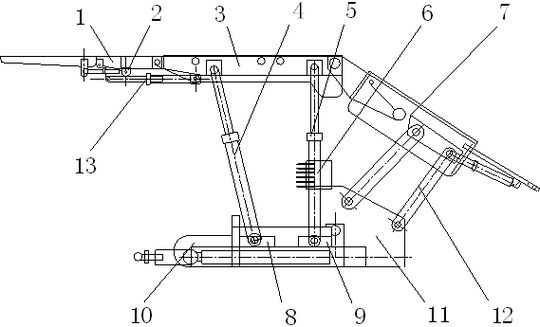

[0013] Embodiment 1: The virtual 3D linkage display scheduling system includes: front beam 1, front beam sensor 2, main beam 3, first support cylinder 4, second support cylinder 5, control box 6, rear push beam 7, first sensor 8. Second sensor 9, walking chassis 10, rear seat 11, rear seat support 12 and front beam cylinder 13;

[0014] The front beam 1, the main beam 3 and the rear push beam 7 are sequentially connected, the front beam sensor 2 and the front beam cylinder 13 are connected to the bottom surface of the front beam 1; the first support cylinder 4 is connected between the main beam 3 and the walking chassis 10 and the second support cylinder 5, the first sensor 8 and the second sensor 9 are respectively connected to the bottom surface of the first support cylinder 4 and the second support cylinder 5, and the control box 6 is connected to the middle part of the second support cylinder 5; The rear portion of chassis 10 is connected with rear seat 11, and is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com