Kite wind power generation system

A wind power generation system and kite technology, which is applied to wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of poor control stability, poor power quality, and high power generation costs, and achieve the effect of simple and easy cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

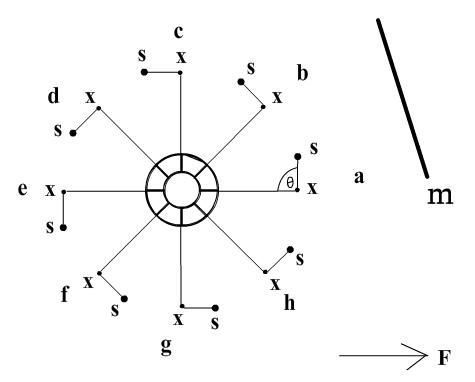

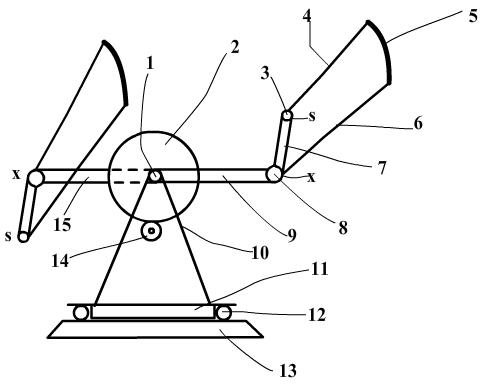

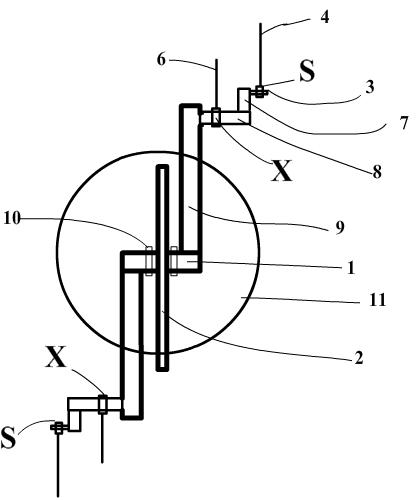

[0026] Example 1 The kite wind power generation device with the turntable placed vertically

[0027] This example is described in conjunction with accompanying drawings 2, 3 and 4. Accompanying drawing 2 is a side view of the turntable placed vertically, and accompanying drawing 3 is a top view of the device. In the accompanying drawing 2, the turntable is composed of a swing arm 9 and a swing arm 15 surrounding the central shaft 1. The swing arm 9 and the swing arm 15 are respectively located on both sides of the gear 2. The angle between the two swing arms is 180 degrees. The turntable and the gear Supported by feet 10, it is installed on a horizontal platform 11 that can rotate 360 degrees, and the rotating platform is installed on a base 13. At the end of the swing arm, a rear control line mooring shaft 8 is installed. On the head of the shaft 8, a support arm 7 with an angle greater than 90 degrees with the swing arm is installed. At the end of the support arm 7, The...

example

[0031] Example 3 The kite wind power generation device with the turntable placed horizontally

[0032] This example is illustrated in conjunction with Figure 6. In Fig. 6, the turntable is composed of four swivel arms 68 surrounding the central rotating shaft 61 of the turntable. The inner ends of the swivel arms are installed on the shaft 61. The four swivel arms are all on the same plane of the horizontal plane, and the four swivel arms equally divide a circle. Axle 61 is installed on the support 610, and gear 69 is equipped with at the bottom of the rotating shaft, by which the power of the rotating disk is transmitted to the working mechanical generator 611 to generate electricity. On the outer end of each swing arm 68, the rear control line mooring shaft 63 is installed, and above the 63, the support arm 66 with an angle of 90 to 180 degrees with the swing arm is installed. On the outer end of 66, a front The control line is tied to the shaft 64, the front control line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com