Measuring method and device for deviation of shape of sealing head of pressure container

A deviation measurement and pressure vessel technology, applied in the field of pressure vessel head shape deviation measurement, can solve problems such as inconvenience, inability to intuitively and accurately reflect the head shape deviation, etc., and achieve reasonable structure, reliable scientific means, and novel conception. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

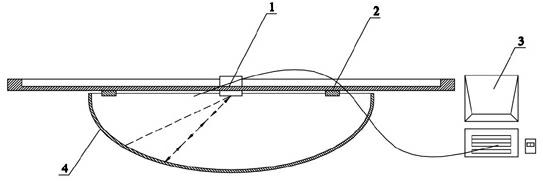

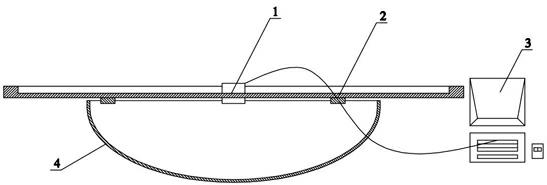

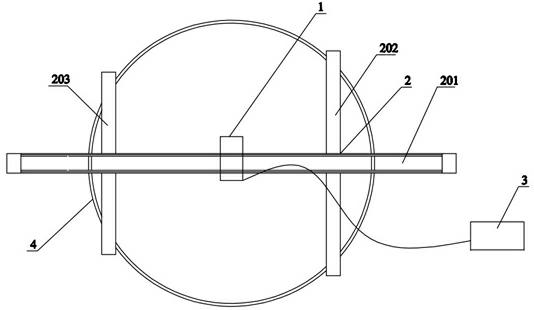

[0026] Pressure vessel head shape deviation measurement method, based on the laser distance sensor and angle sensor to obtain the two-dimensional polar coordinate value of the target point. After the rectangular coordinate value conversion and the least square fitting process, the drawing is implemented, and it is determined by comparing with the standard shape of the head The shape deviation is automatically judged whether it is qualified or not, which specifically includes the following steps:

[0027] 1) Calculate and determine the center position of the circular section of the connection port of the head, and place the laser distance sensor and angle sensor at this center position;

[0028] 2) Adjust the laser distance sensor so that the measurement target point is the inner surface position of the circular section of the connection port described in step 1), use the edge position of the head as the starting point of measurement, and calibrate the starting angle of the angle sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com