Concrete beam reverse loading test device

A technology of reverse loading and testing device, applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of inconvenient measurement of crack width and unfavorable experimental data, and achieve convenient and accurate loading control, arbitrary movement, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

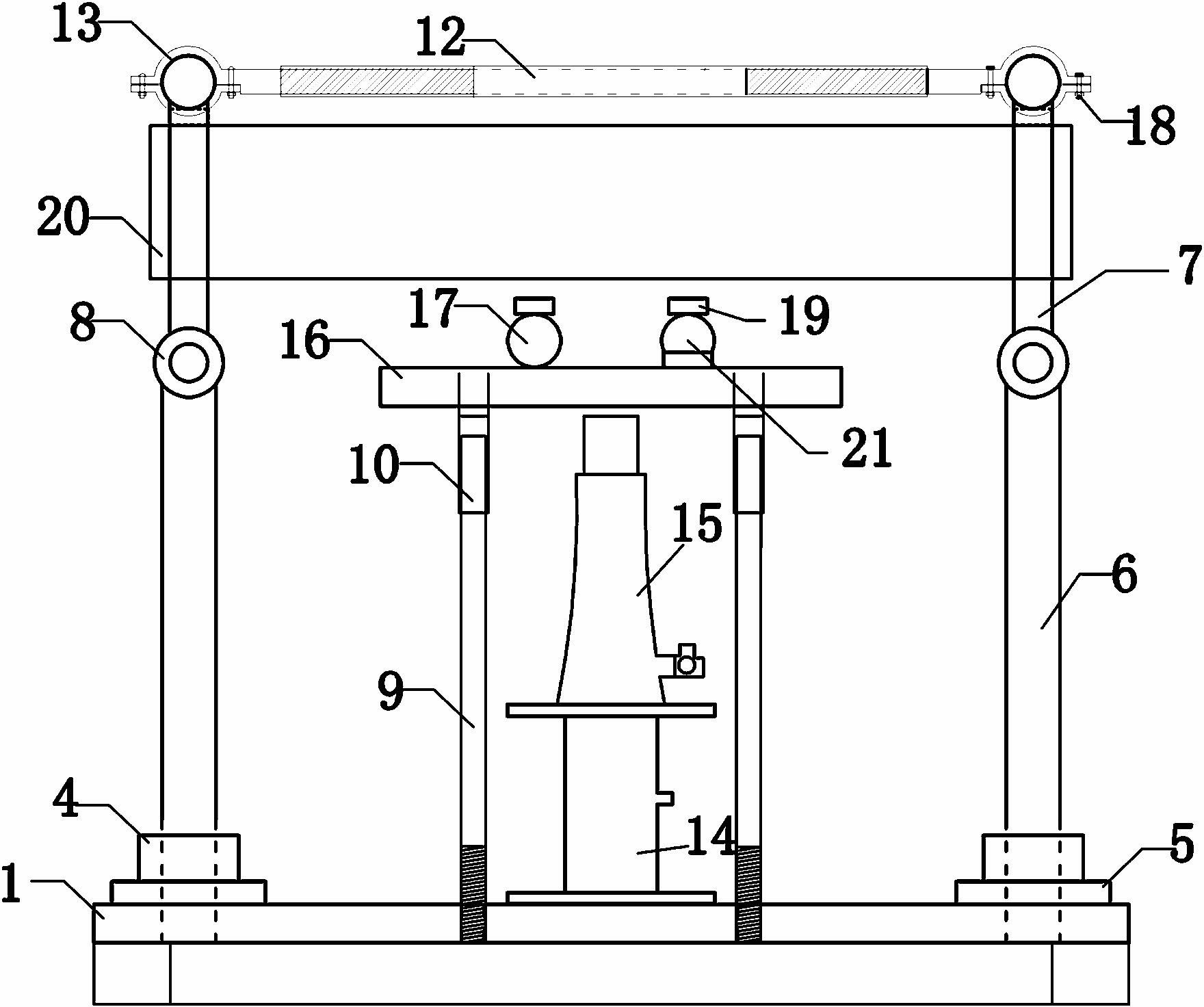

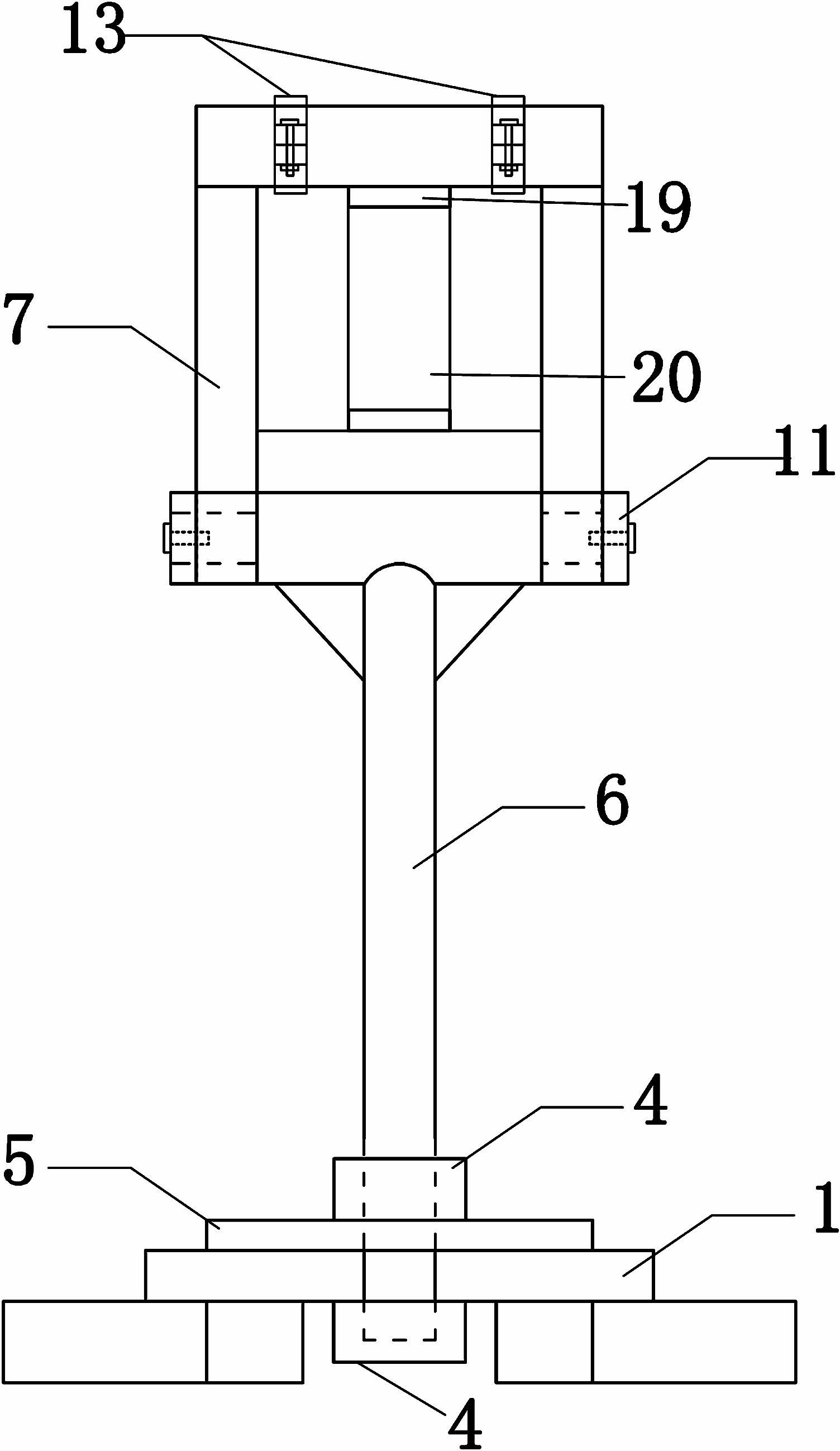

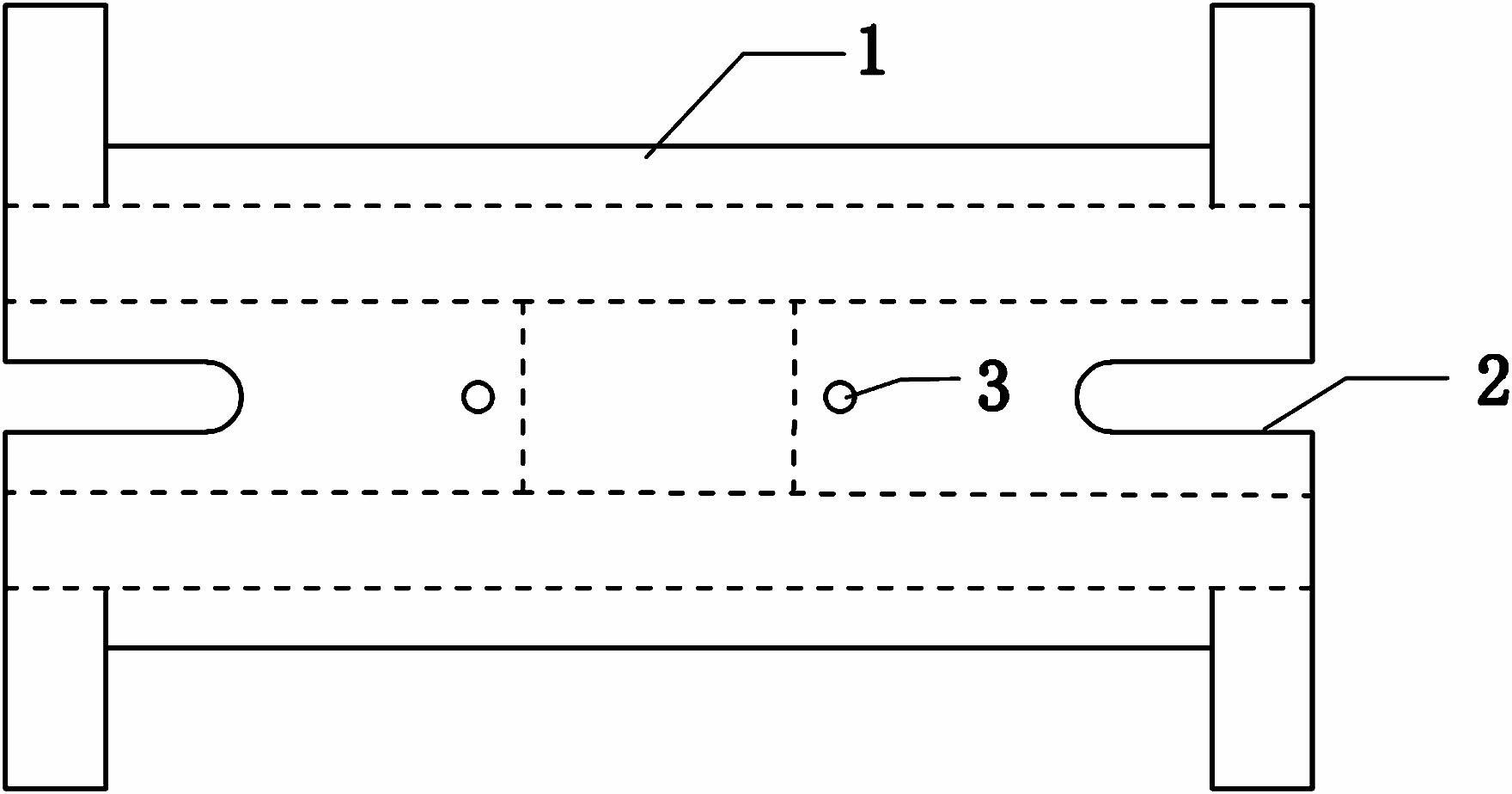

[0021] like figure 1 , image 3 Among them, a concrete beam reverse loading test device includes a base 1, chute 2 is provided at both ends of the base 1, and the support rod 6 is installed in the chute 2 through a nut 4; The nut 4 below is located in the "Ω"-shaped concave part. A reinforced backing plate 5 is also provided under the upper nut 4 to ensure that the support rod 6 is reliably stressed.

[0022] The support rod 6 is connected with the support frame 7, and the two support frames 7 are connected by a transverse tie rod 12;

[0023] like figure 1 Among them, a support rod 9 is provided on the inner side of the chute 2 on the base 1, and the support rod 9 is connected with the fixing hole 3 on the base 1 through threads, so that the height of the support rod 9 can be adjusted to suit different test pieces 20.

[0024] The support rod 9 is movably connected with the distribution beam 16 . In a preferred solution, a support groove 10 is provided at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com