Grounding wire hook for overhead transmission line power cut overhaul

A technology of overhead transmission lines and grounding wires, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of loss of grounding function, reducing the scope and time of power outages, and achieving the effects of improving safety, reasonable structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

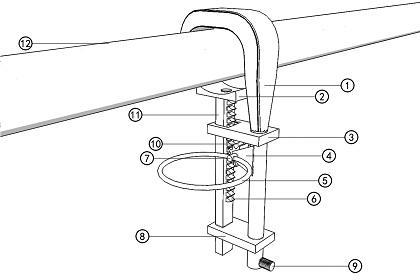

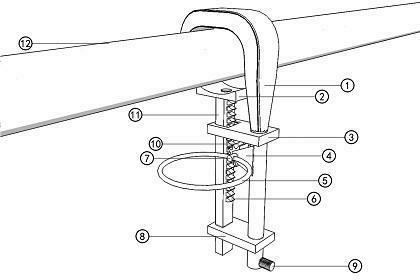

[0011] From figure 1 It can be seen from the figure: a grounding wire hook for power failure maintenance of overhead transmission lines (referred to as the grounding wire hook), which is characterized in that: the grounding wire hook for power failure maintenance of overhead transmission lines is mainly composed of a hook body 1, a lower pressure plate 2, and an upper fixing plate 3. Ear plate 4, operating ring 5, rack 6, gear shaft 7, lower fixing plate 8, grounding stake 9 and gear 10. The upper part of the hook body 1 is an arc-shaped hook section extending to the left. The cross-section of the section can be rectangular or flat, and the bottom of the hook body 1 is a cylindrical section, and the cylindrical section of the hook body 1 is fixedly installed in the circular through hole on the right part of the upper fixing plate 3 and the lower fixing plate 8 and its lower end section Stretch out lower fixed plate 8 downwards, on the cylindrical section of hook body 1, corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com