High-speed motor

A technology of high-speed motors and vacuum machines, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problem that the motor speed cannot be increased, and achieve the effect of weakening the cracking phenomenon of the inner and outer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

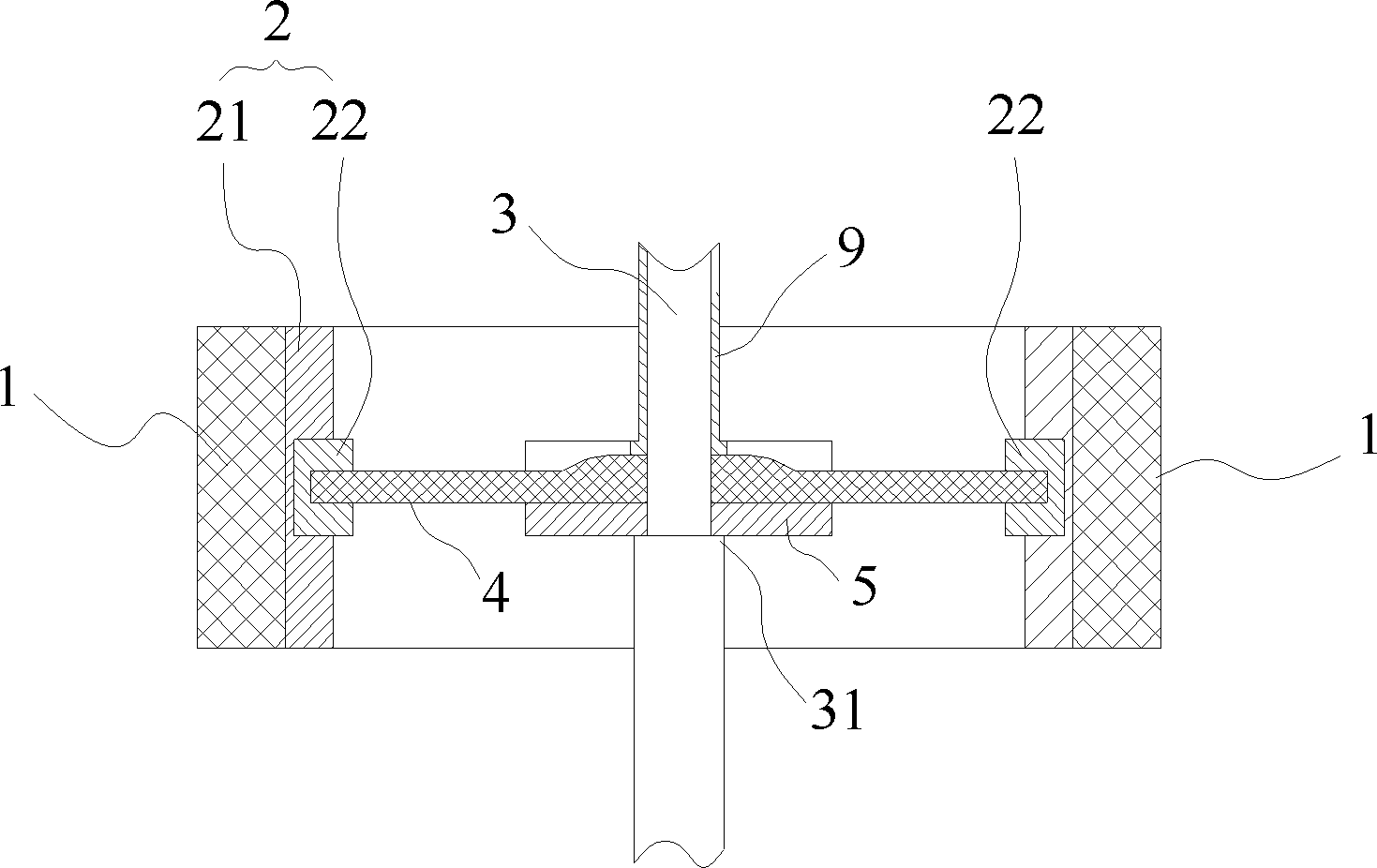

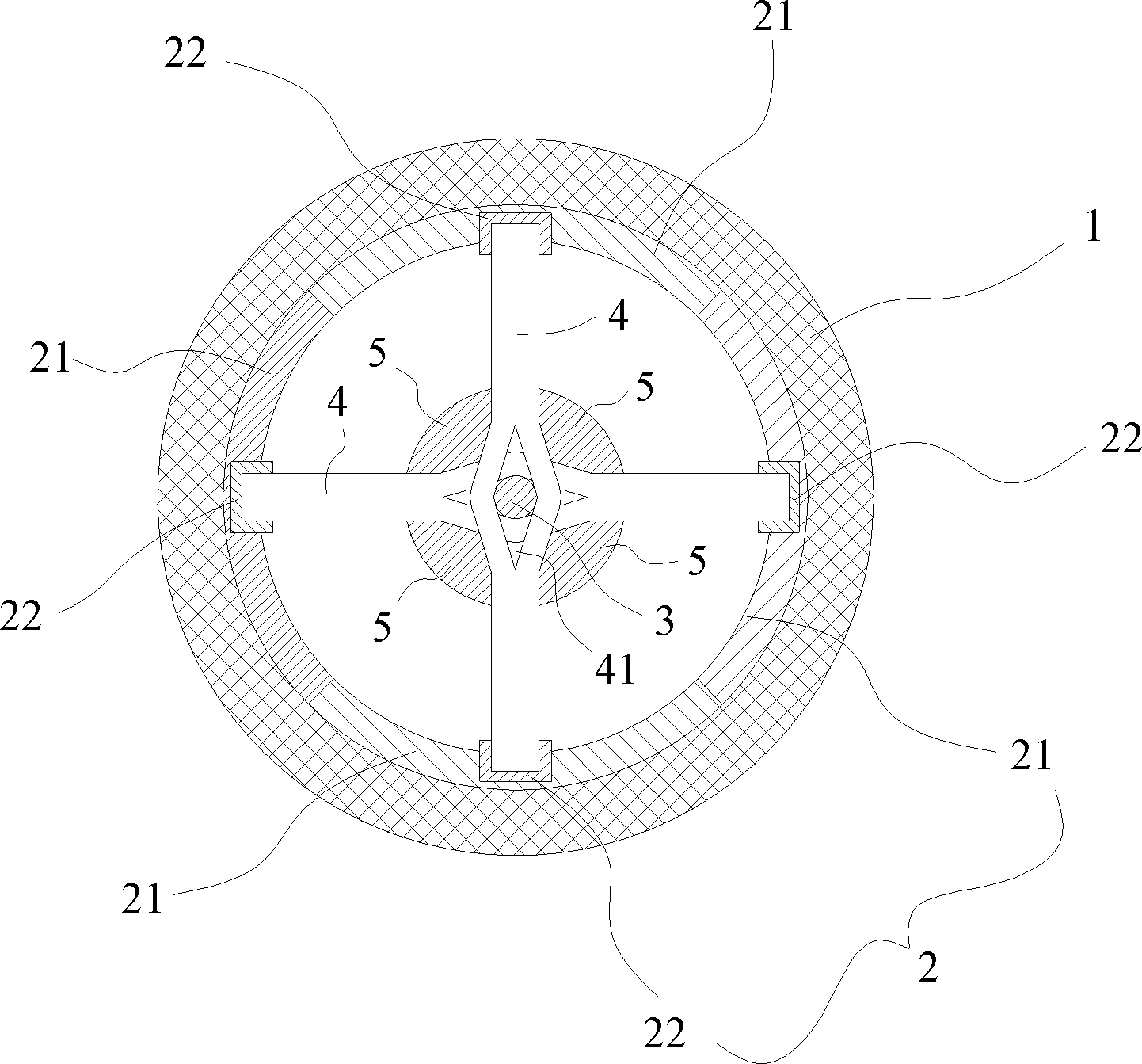

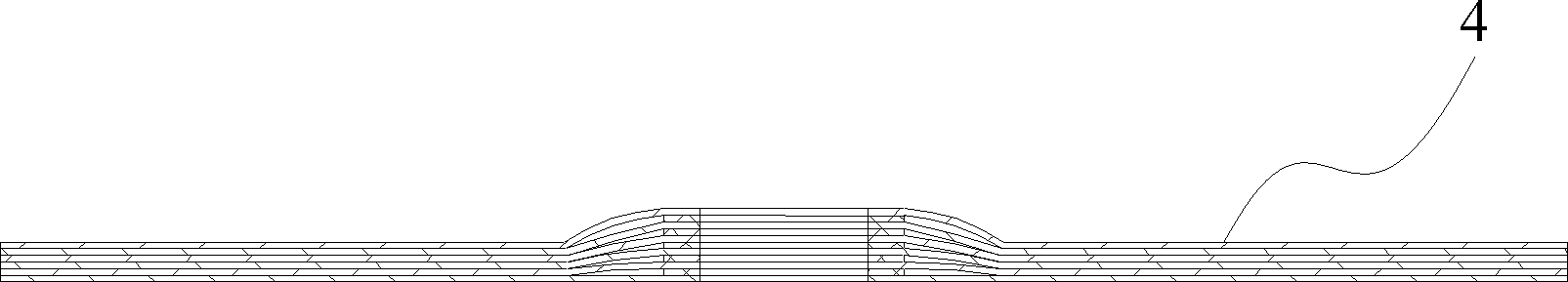

[0036] refer to figure 1 , figure 2, The rotor of the high-speed motor of the present invention includes: a cylinder 1 , a hub 2 set in the cylinder 1 , a shaft bar 4 connected to the hub 2 and a rotating shaft 3 . The cylinder 1 is made of high-strength fiber composite material, the hub 2 is made of metal, and the cylinder 1 is sleeved on the outer wall of the hub 2 to help the hub 2 bear centrifugal force. The hub 2 is assembled by a plurality of circular arc plates 21, and an axle sleeve 22 is arranged on the inner wall of each arc plate 21. The axle bars 4 are connected to the rotating shaft 3 and distributed radially along the hub 2. The freedom of each axle bar 4 The ends are respectively inserted in the shaft sleeves 22 of the circular arc plates 21 and are interference-fitted with the shaft sleeves 22 in the radial direction of the hub 2 .

[0037] The shaft sleeve 22 can be protrudingly arranged on the inner wall of the arc plate 21 , and can also be embedded in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com