Combine harvester

A combine harvester and fan technology, applied in agricultural machinery and implements, threshing equipment, agriculture, etc., can solve the problem that the separation device cannot be used for maximum effect, complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] When reading the following description, it should be understood that the terms longitudinal and transverse are relative to the normal direction of travel of the combine harvester. In other words, the term portrait is equivalent to the front-rear direction, and the term landscape is equivalent to the landscape or left-right direction. Also, the terms axial and radial are relative to a rotating body such as a shaft, wherein axial is equivalent to a direction along the axis of rotation and radial is equivalent to a direction perpendicular to the axis of rotation.

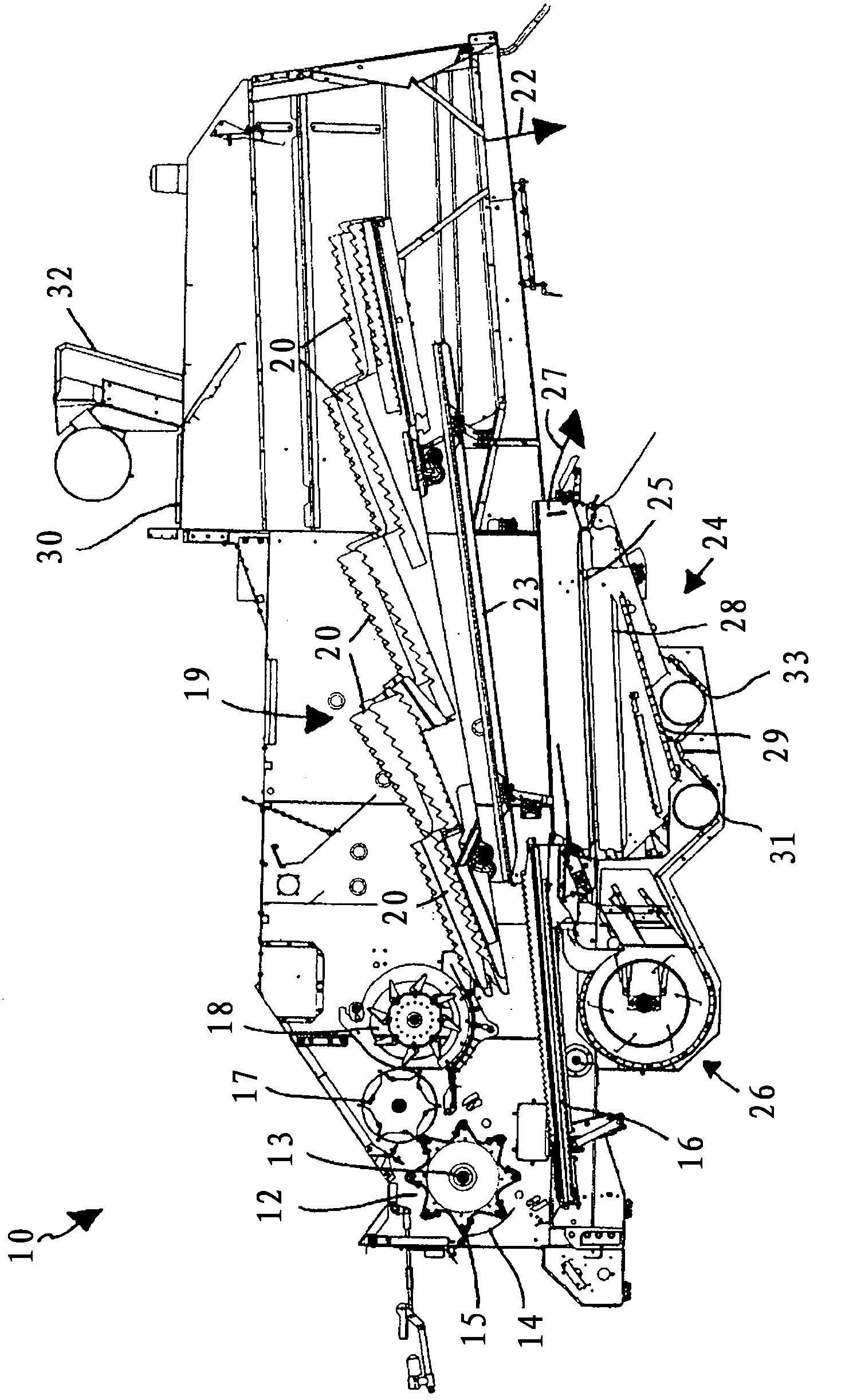

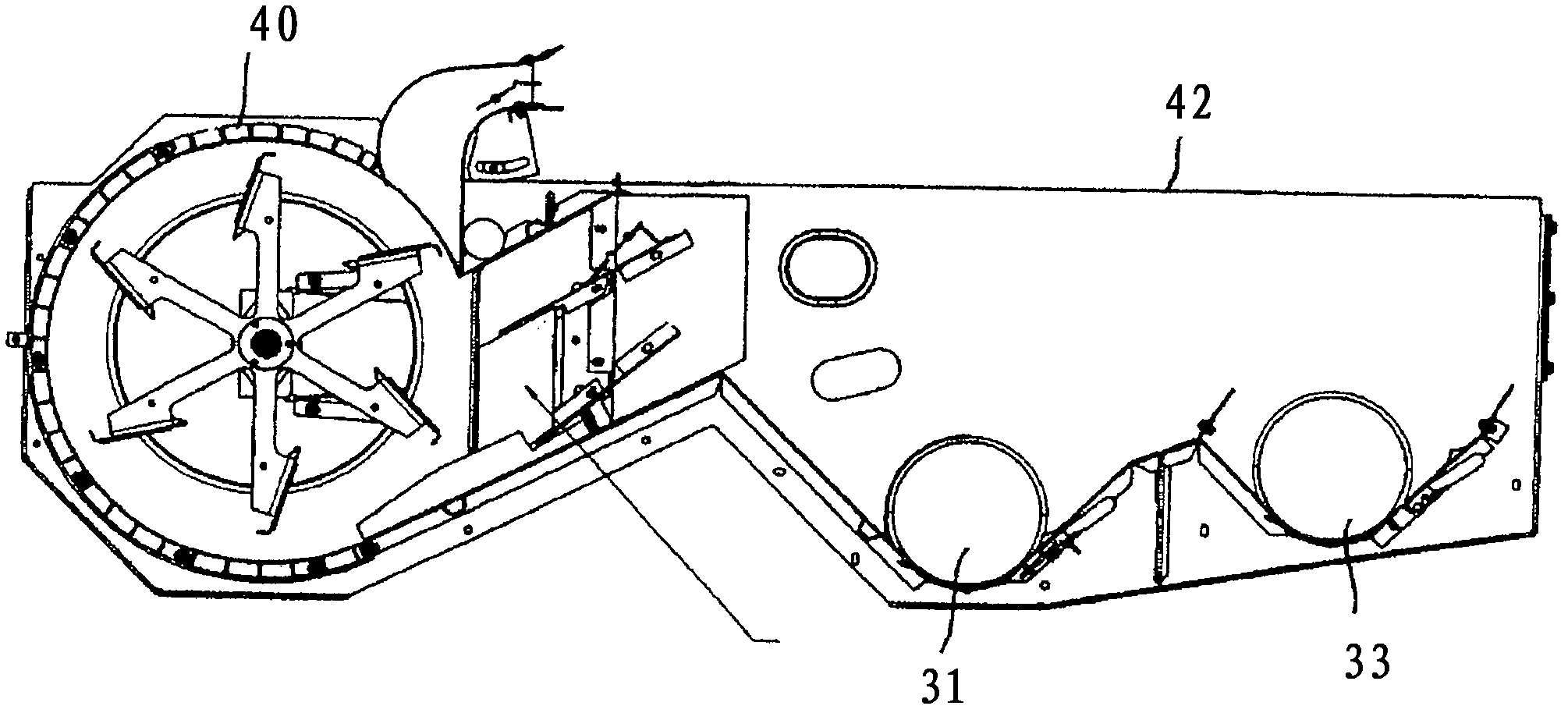

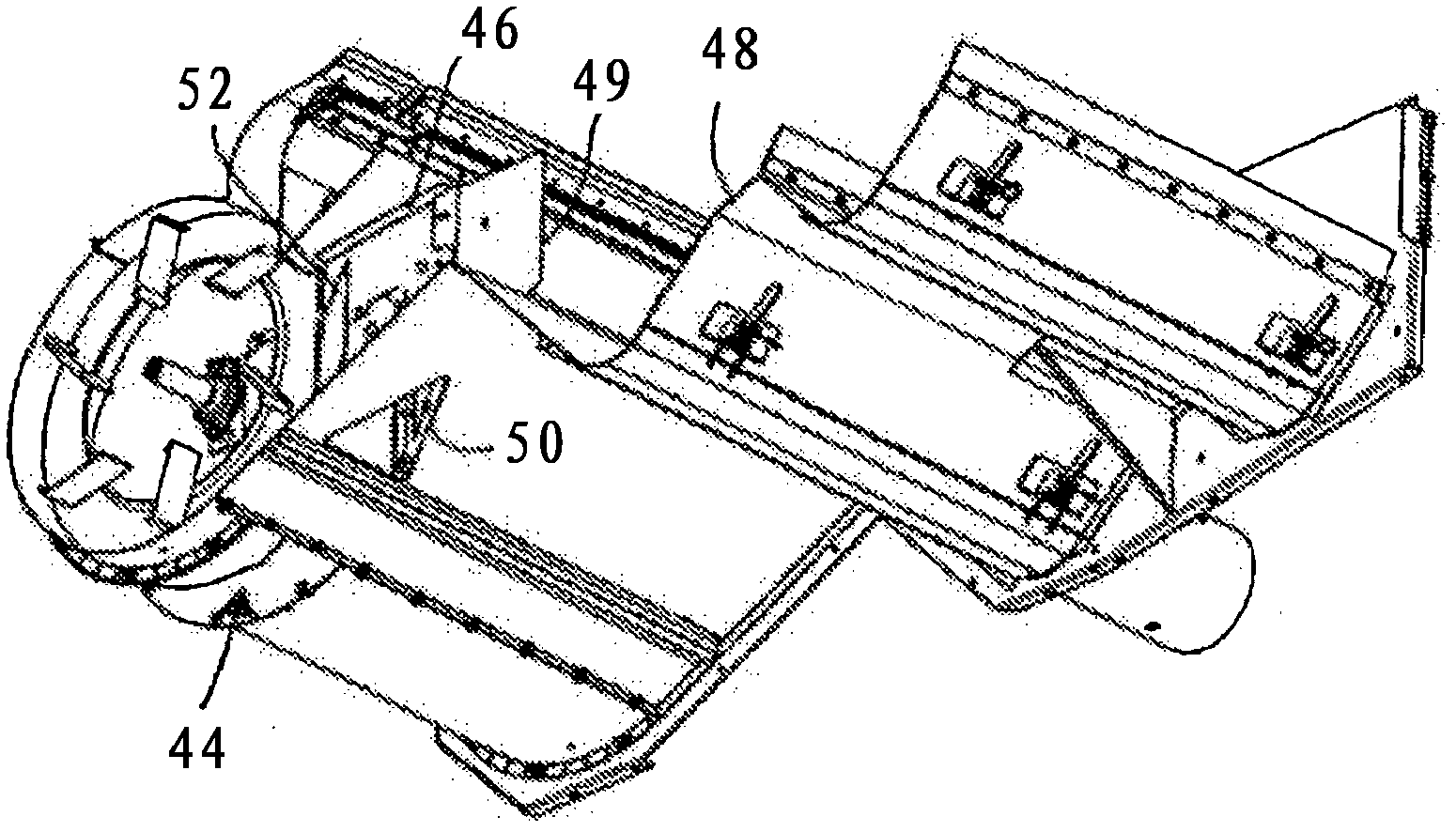

[0024] refer to figure 1 , combine harvester 10 includes a header (not shown) that cuts crops as harvester 10 drives across a field. The crop is conveyed by elevators (also not shown) to the threshing drum (generally indicated at 12). The threshing drum 12 rotates on a transverse axis 13 within a drum shell 14 . Breakaway bars 15 cause the grain to be threshed from the heads of each plant and a portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com