A trajectory planning method for air-spraying irregular curved pipe inner wall thickness coating trajectory

A technology of air spraying and trajectory planning, applied in the direction of spraying devices, can solve the problems of low spraying efficiency, poor flexibility, and large overall size, and achieve the effect of overcoming structural design problems, improving horizontal uniformity, and ensuring vertical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

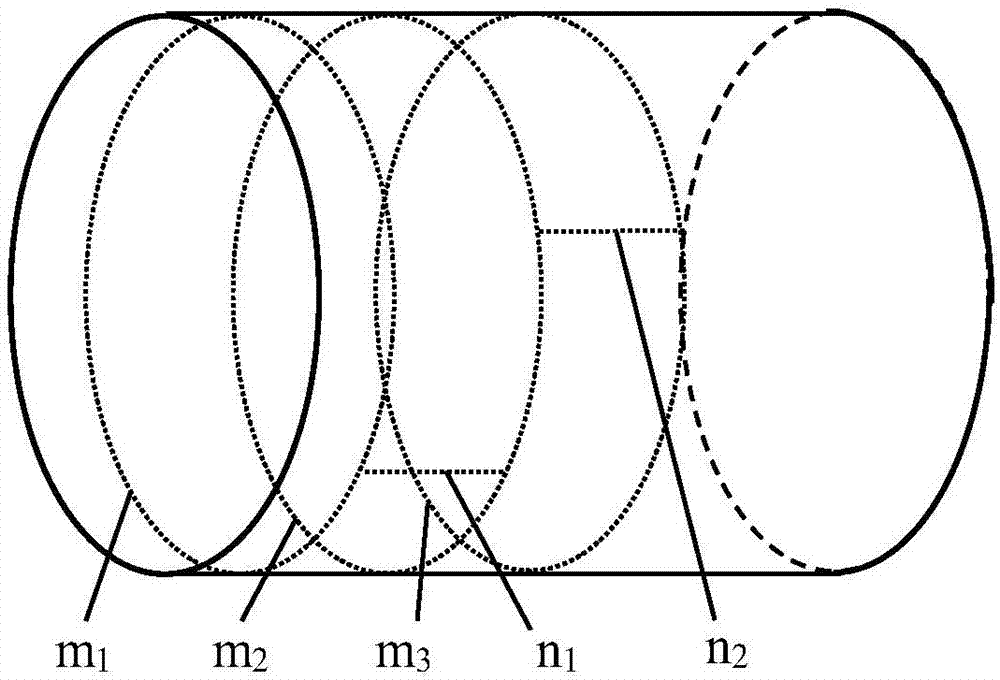

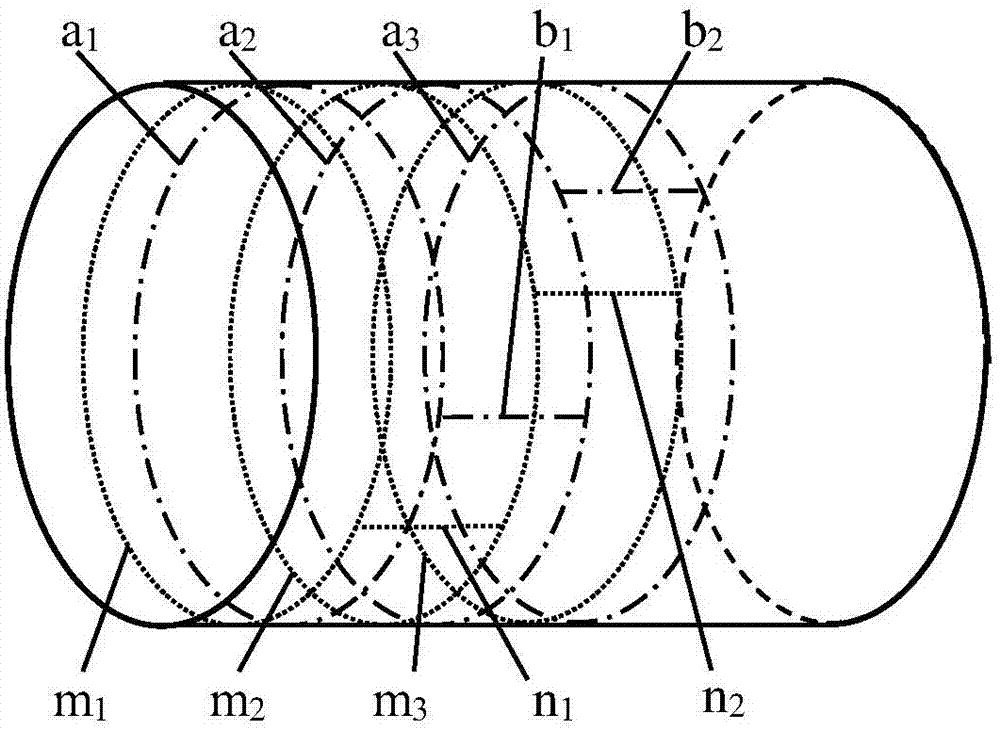

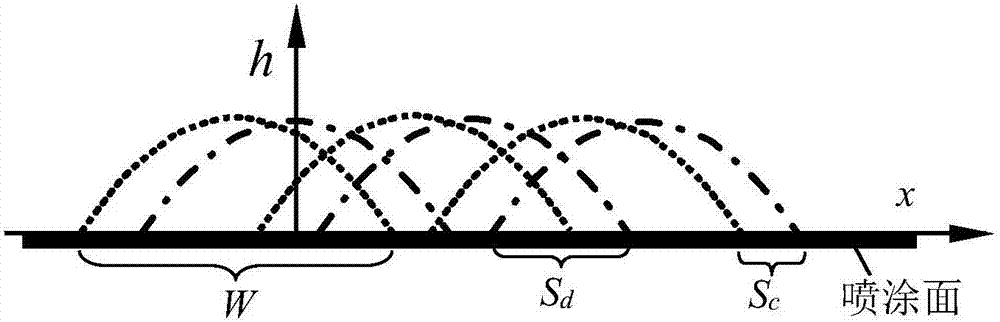

[0034]The air spray coating trajectory planning method for irregularly curved pipe inner wall thickness is used to plan and determine the spraying operation trajectory of the spray gun of the spraying robot on the inner wall of the irregularly curved pipe, and in order to facilitate the simplification of the structure design of the spraying robot, Taking into account the improvement of the uniformity of the sprayed thick coating, the following planning ideas are adopted: First, the misalignment spraying method with optimized lap width and misalignment distance is used to plan and determine the spraying path, and the horizontal intermittent trajectory spraying method does not require the spray gun of the spraying robot When spraying, it always rotates continuously in a single direction, so there is no need fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com