A water storage and distribution system having a water tank by pass

A water tank and water distribution technology, which is applied in transportation and packaging, railway car body parts, sanitary equipment, etc., can solve problems such as inability to serve and affect the comfort of railway passenger passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

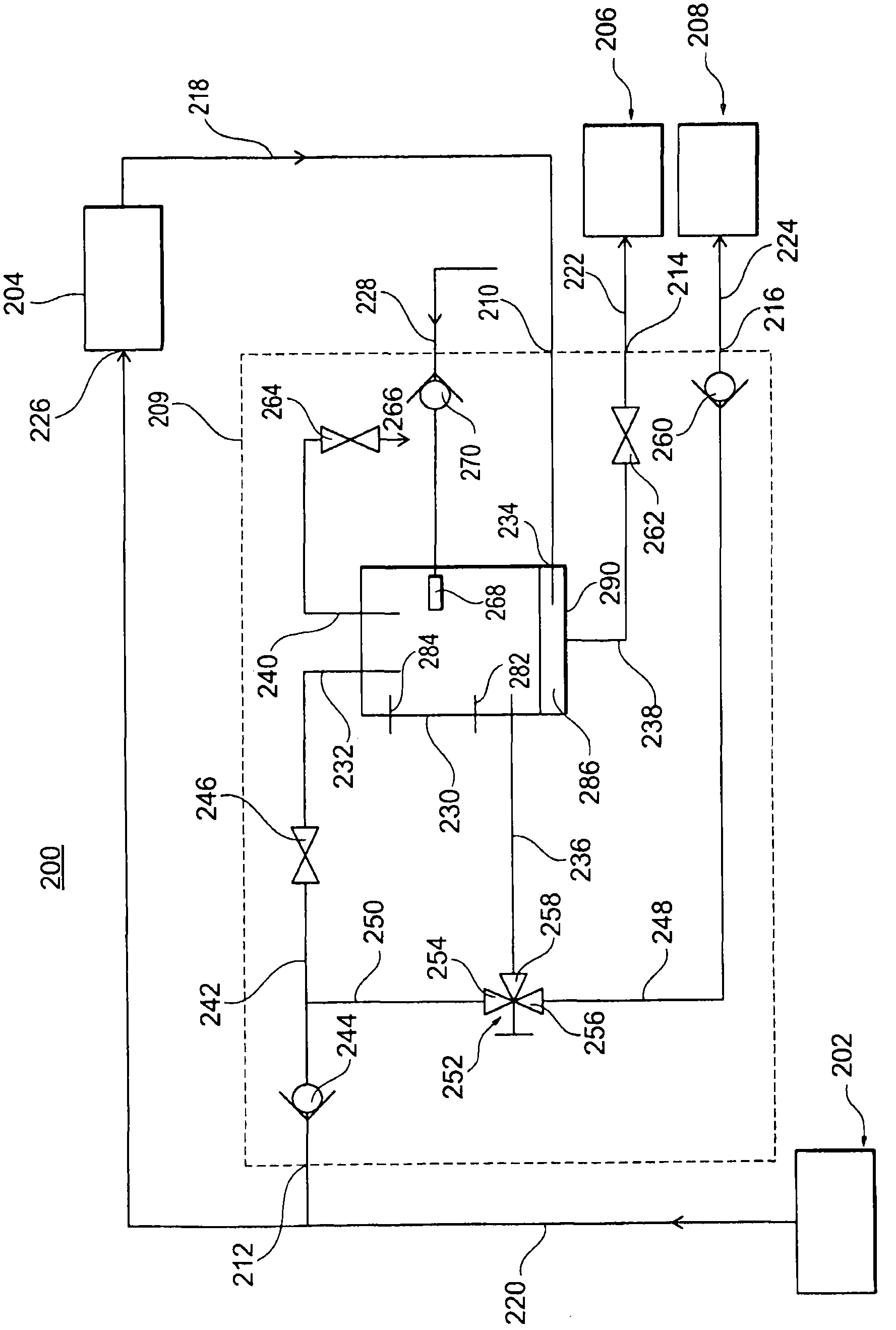

[0033] figure 2 Shown is a sanitary fixture 200 according to the invention. The sanitary fixture 200 is mounted on a vehicle such as a railway passenger car. The main components of the sanitation fixture 200 are clean water tank 202 , basin 204 , dirty water tank 206 , toilet 208 , and a water storage and distribution system, ie a toilet water recovery system 209 . The toilet water recovery system 209 has a toilet water input unit 210 , a purified water input unit 212 , a sewage output unit 214 , and a flush water output unit 216 . The toilet water input 210 is connected to a drain 218 of the basin 204 . The clean water input part 212 is connected to the water outlet 220 of the clean water tank 202 . The sewage output 214 is connected to the water inlet 222 of the sewage tank 206 . The flush water output 216 is connected to a water inlet 224 of the toilet 208 . The clean water faucet 226 on the water basin 204 is connected to the water outlet 220 on the clean water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com