Pin shaft connecting structure, assembling and disassembling methods thereof and tower crane

A technology of connection structure and installation method, applied in the directions of cranes, pivot connections, bolts, etc., can solve the problems of increasing transportation costs, increasing the transportation height of the boom, and inconvenient transportation of the boom, and achieves lower transportation height and lower transportation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

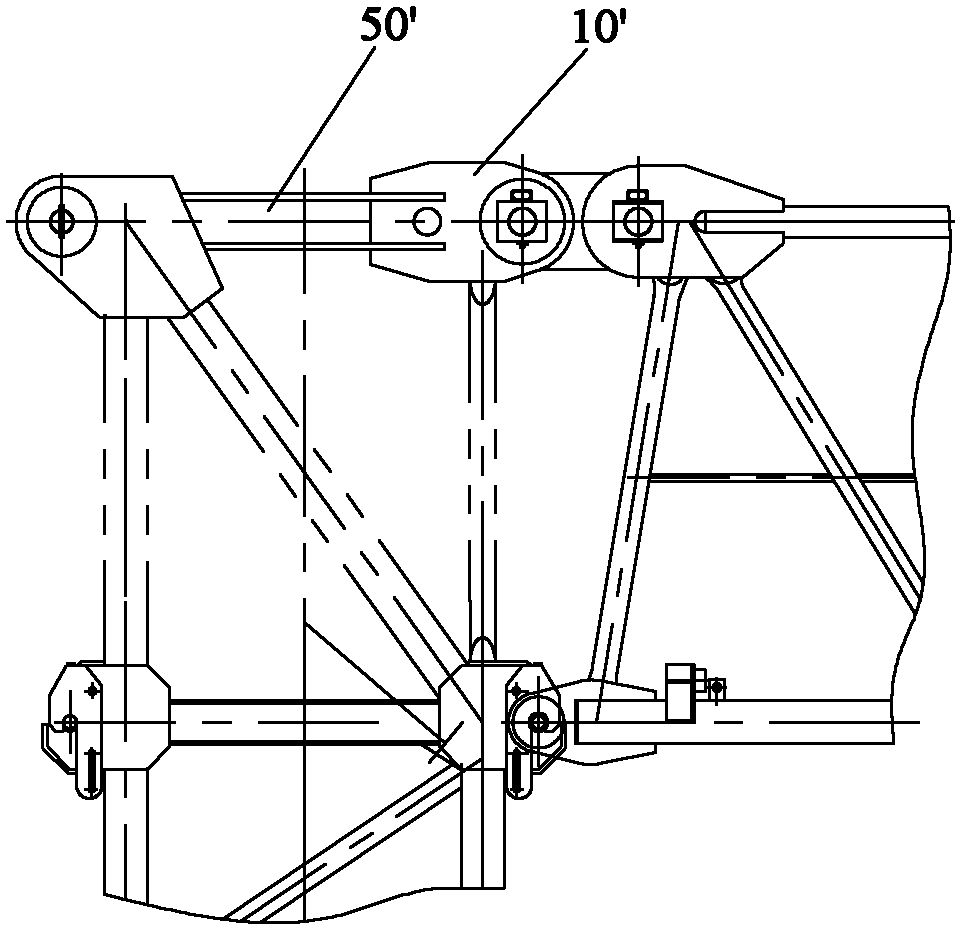

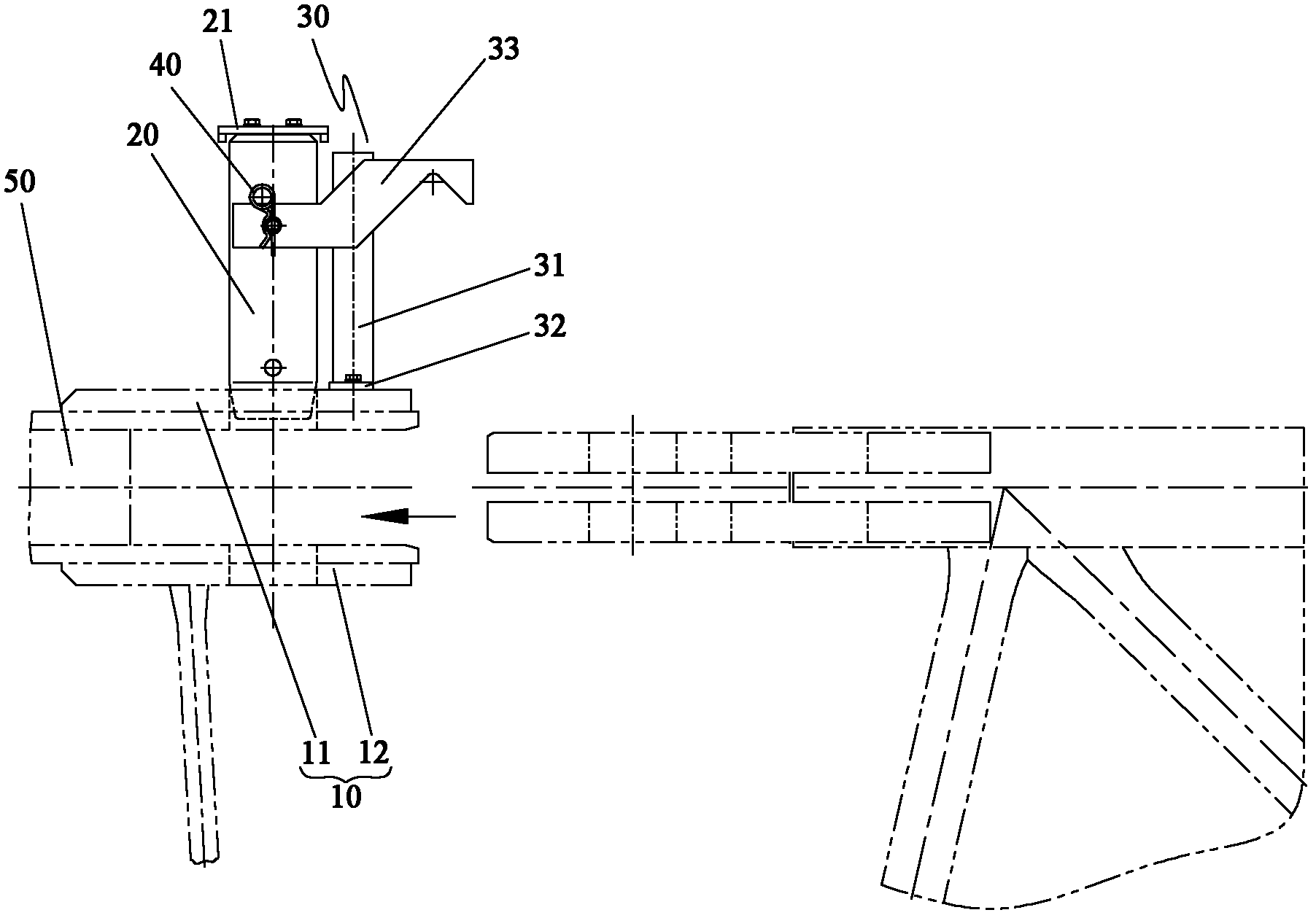

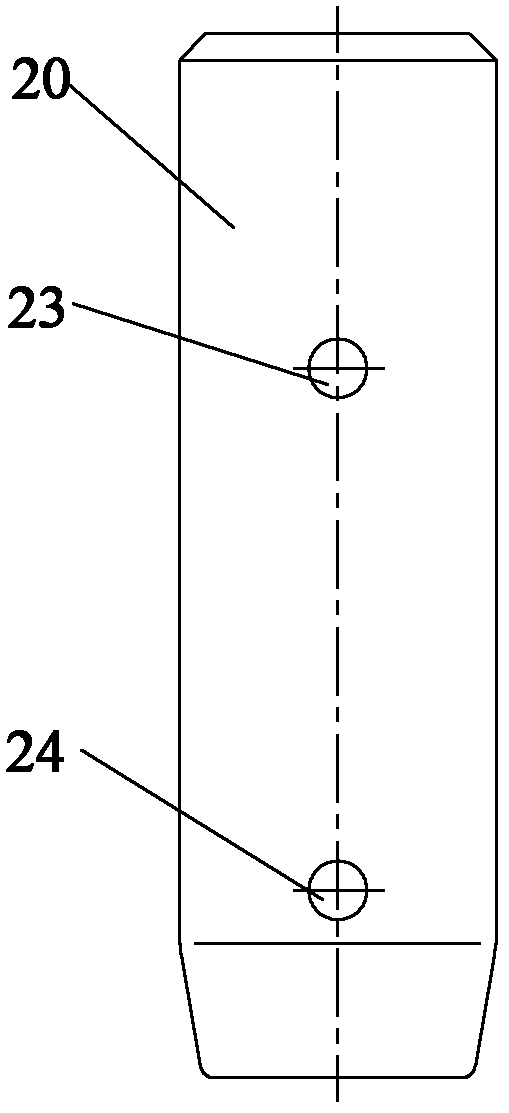

[0031] like Figure 2 to Figure 10 As shown, according to the embodiment of the present invention, the pin connection structure includes a pin connection lug 10 , a connection pin 20 , and a pin bracket 30 . The two pin-shaft connection lugs 10 are fixedly connected to the ends of the chord 50 and arranged relatively parallel. The two pin connecting lug plates 10 include an upper connecting plate 11 arranged above and a lower connecting plate 12 arranged below. Both the upper connecting plate 11 and the lower connecting plate 12 are fixedly connected to the chord 50 horizontally and horizontally. The upper connecting plate 11 and the lower connecting plate 12 are oppositely provided with pin connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com