Asphalt mixture viscoelastic property test method based on wheel load instrument

A technology of asphalt mixture and test method, which is applied in the direction of testing material strength by applying stable tension/compression, and testing material strength by applying repeated force/pulsation force, so as to achieve accurate and reliable viscoelastic performance, operability and applicability strong effect

Inactive Publication Date: 2012-08-08

CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

View PDF1 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that at the same time that LWT is widely used in the world, it is a good way to use resources rationally and save costs by using its own characteristics and advantages to develop new and effective test methods.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

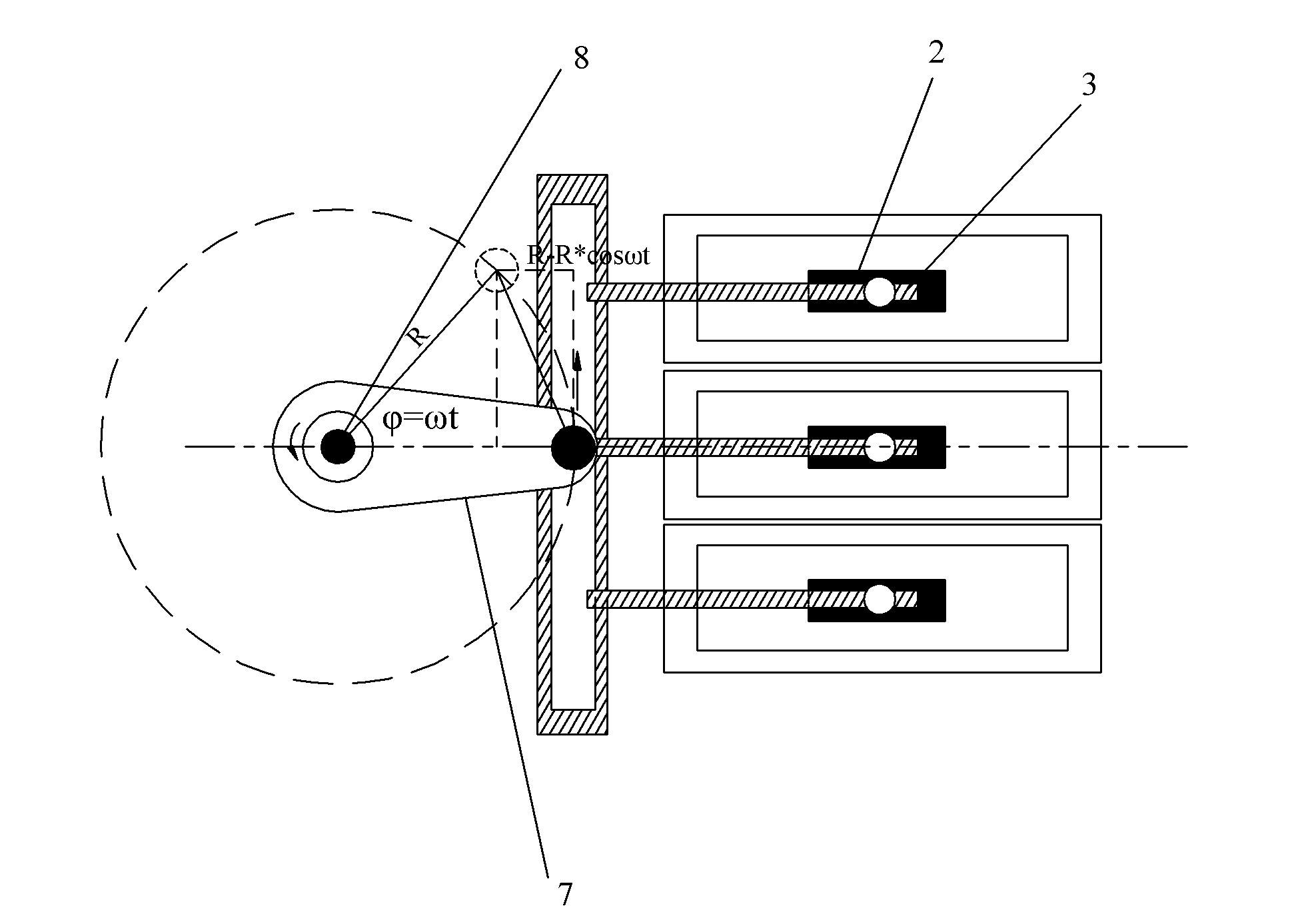

[0036] This embodiment takes the LWT wheel-loaded system based on APA (Asphalt Pavement Analyzer) as an example, and uses the test method of the present invention to carry out viscoelastic performance tests on several different asphalt mixtures.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

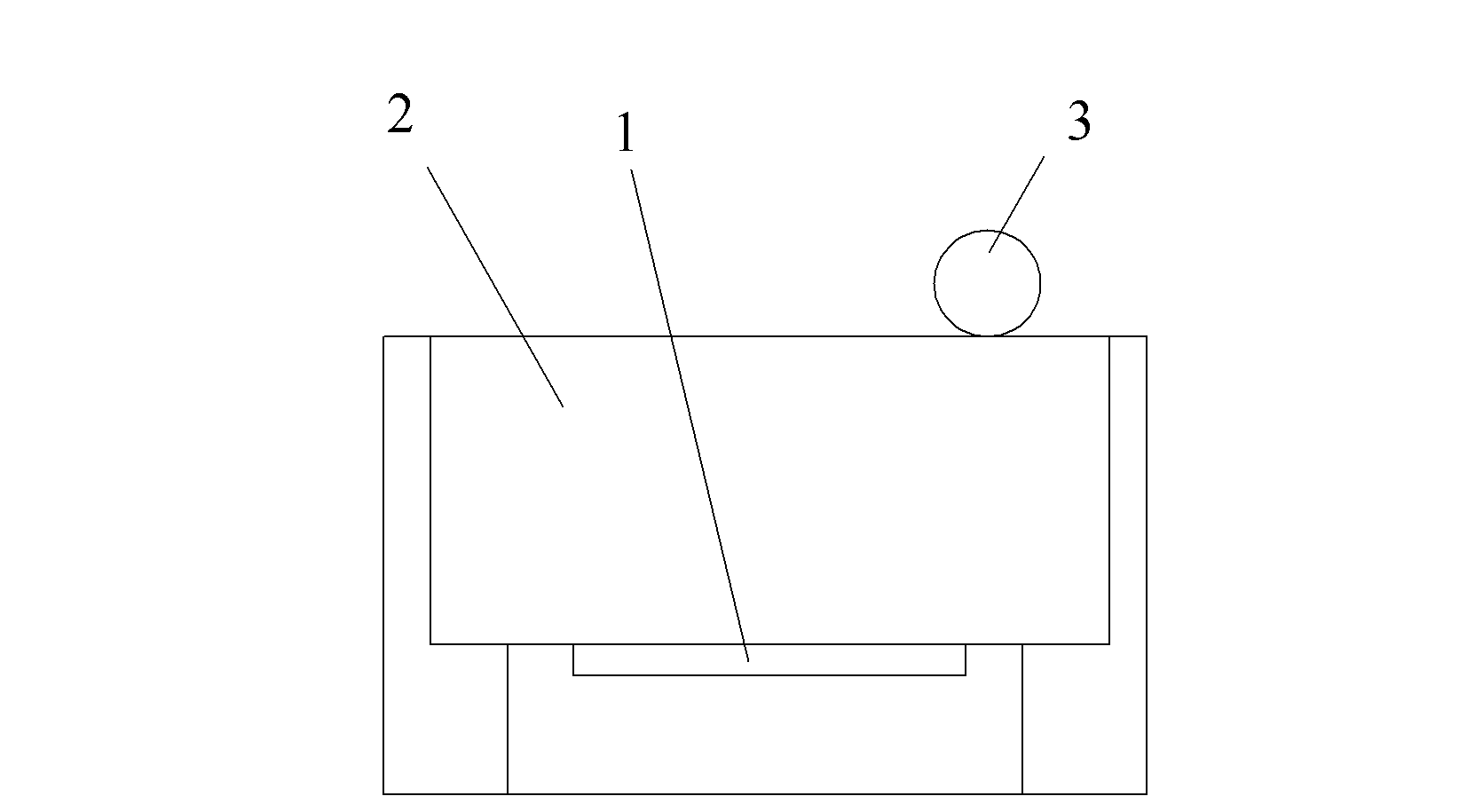

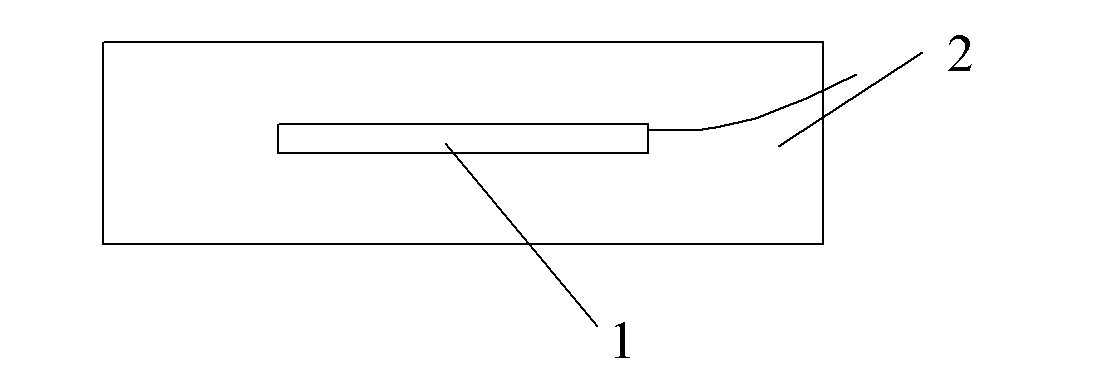

The invention relates to an asphalt mixture viscoelastic property test method based on a wheel load instrument. In the method, the wheel load instrument, a test piece, a dynamic modulus test and a creep test are provided. The method comprises the following steps: a, before the test, assembling a strain sensor at the bottom of an asphalt mixture test piece and calculating by a mechanical method or a finite element analysis method to obtain the stress distribution condition of the test piece under the action of moveable load according to moving wheel load features and the test piece size; b, during the test, employing the modulus test and the creep test: measuring the tensile deformation strain capacity of the test piece by using the strain sensor, and measuring the tensile deformation strain capacity of the test piece through the strain sensor; and c, after the test, obtaining the stress and the strain capacity of the test piece and the action time of the wheel load by the wheel load instrument and the strain sensor. The method has the characteristics of simplicity, practicability, high operability and high applicability. According to the method, the stress characteristic of the test piece during the test is similar to the actual asphalt concrete road surface, and the viscoelastic property obtained by the test is accurate and reliable.

Description

technical field [0001] The invention belongs to the field of road engineering, and in particular relates to a test method for the viscoelasticity performance of asphalt mixture based on a wheel load meter, which is used for testing the viscoelasticity performance of asphalt mixture. Background technique [0002] In recent years, the vigorous development of highway traffic, especially the construction of high-grade highways, has put forward higher requirements for the quality and function of road materials. The performance, quality and composition design of road materials play a vital role in its development, and testing and understanding the performance of road materials through reasonable test methods is the premise and basis for the correct and effective use of road materials. Due to its many advantages, asphalt concrete pavement has been widely used in road engineering construction. The current high-grade roads in our country basically use asphalt concrete pavement. [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/32G01N3/08

Inventor 黄宝山吴昊舒翔

Owner CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com