Control method of movement control module of electrosparking machine

A technology of control module and control method, which is applied in electric processing equipment, circuits, manufacturing tools, etc., can solve problems such as troubles, and achieve the effect of convenient tool setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

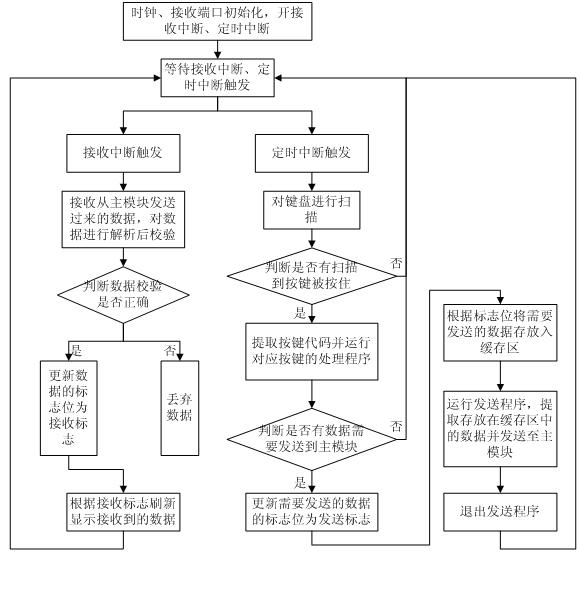

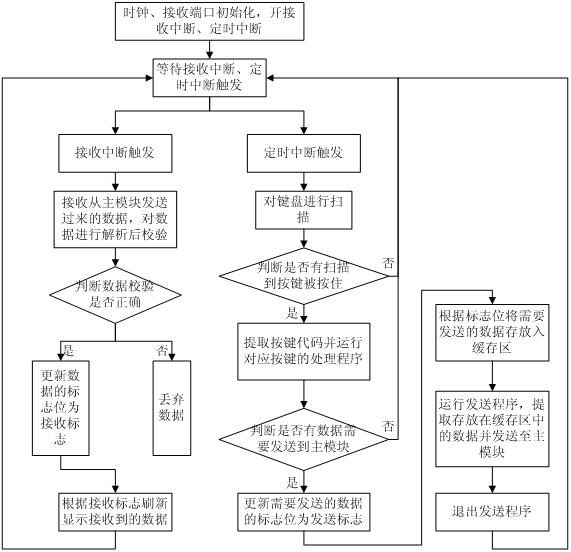

[0022] In order to facilitate the description of the control method of the present invention, the control method of the manual control module of the electric discharge forming machine of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0023] A control method for a mobile control module of an electric discharge forming machine, the control method comprising the following steps:

[0024] 1) Initialize the clock and receiving port in the control chip of the mobile control module, and enable the receiving interrupt of the receiving port and the timing interrupt of the clock;

[0025] 2), wait for receiving interrupt, timing interrupt trigger; if receiving interrupt trigger, go to step 3); if timing interrupt trigger, go to step 4);

[0026] 3) Receive an interrupt trigger, the mobile control module receives the data sent from the main module and analyzes and verifies the data;

[0027] a) Determine whether the data verifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com