Hydraulic press machine of jack

A jack and press technology, applied in the field of press machinery, can solve the problem of inconvenient placement of fasteners, etc., and achieve the effect of enhancing convenience and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

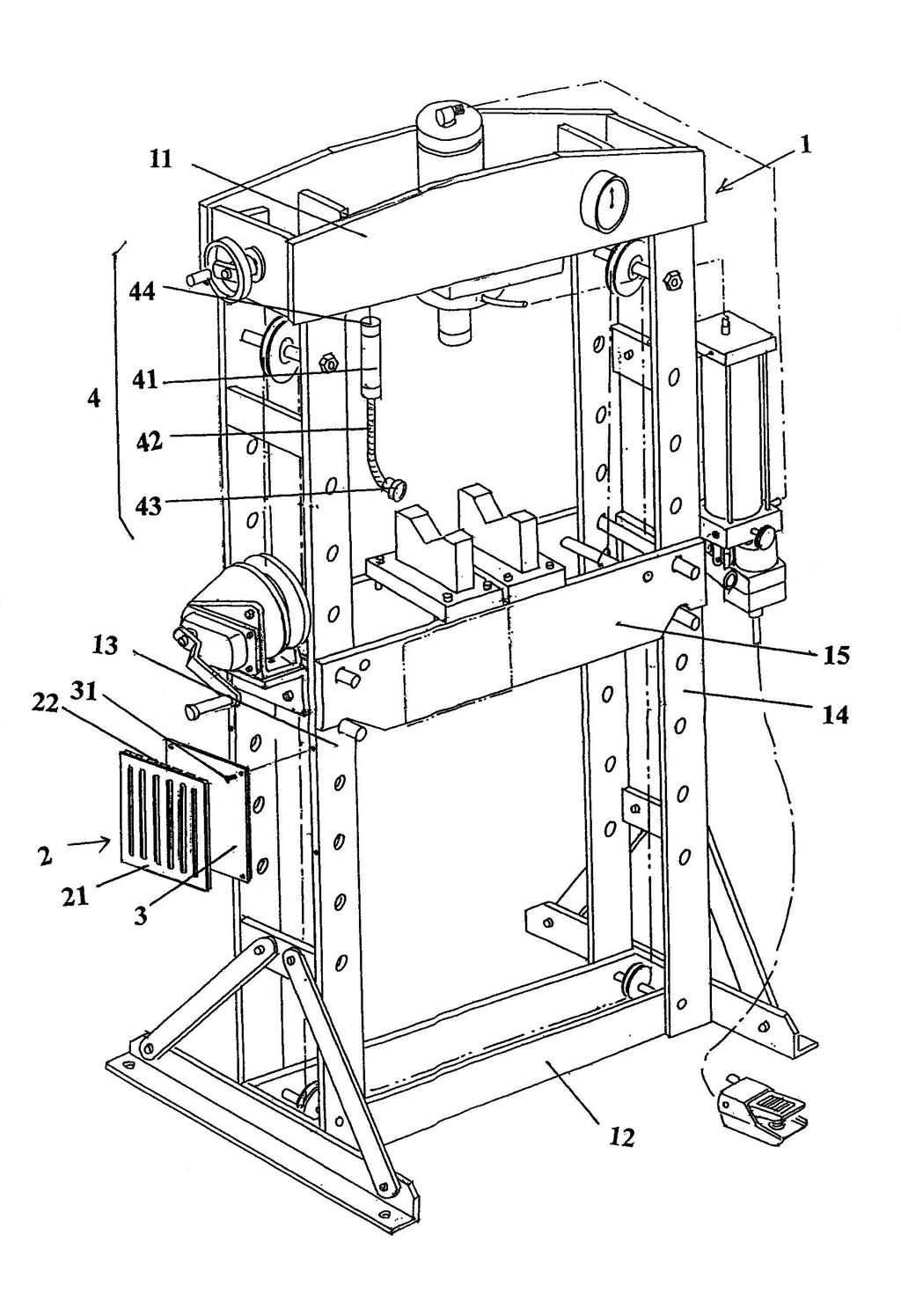

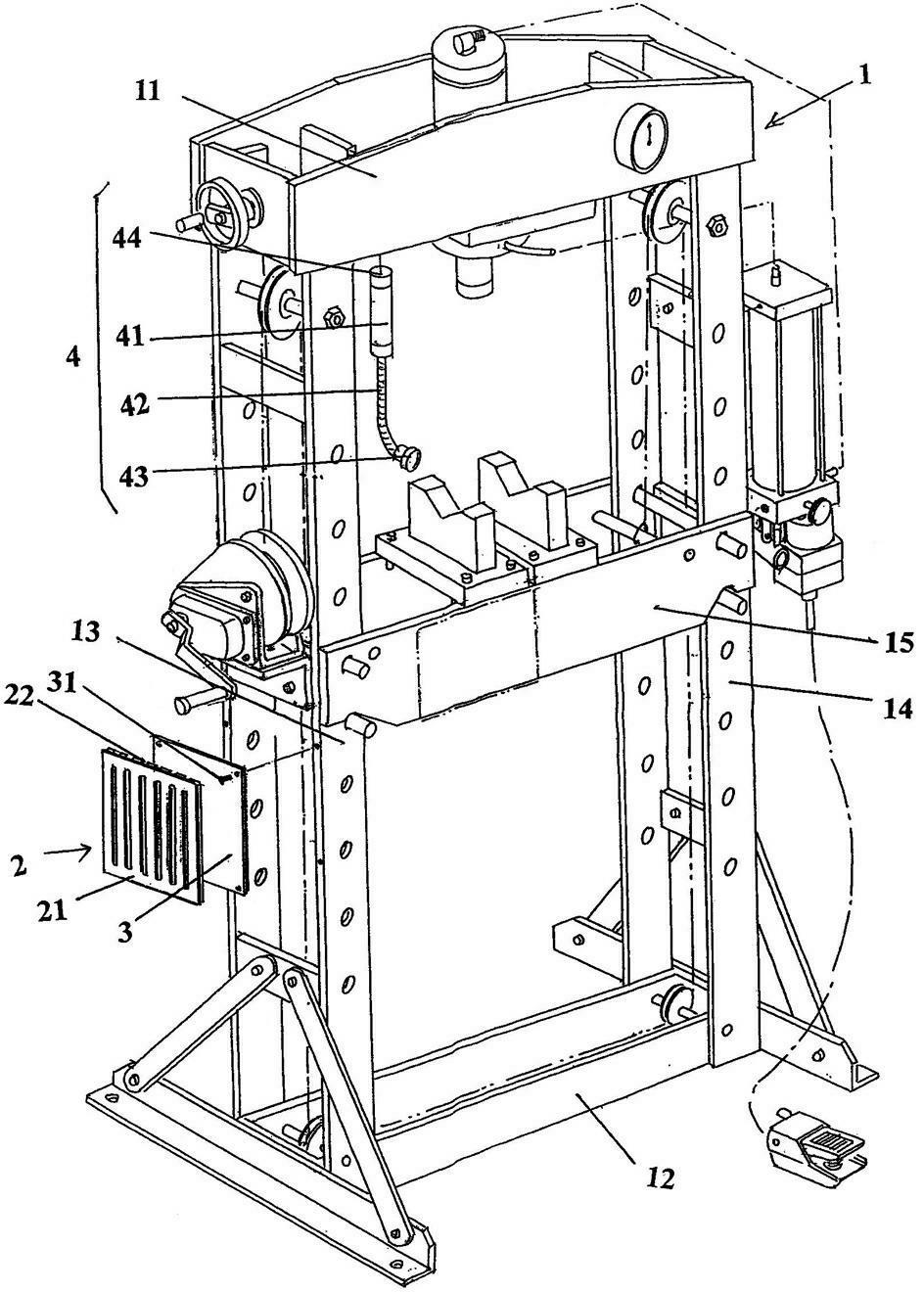

[0020] please see figure 1 , the given frame 1 is composed of upper and lower beams 11, 12, first and second longitudinal arms 13, 14 and workpiece racks 15 connected between the upper and lower beams 11, 12 and kept parallel to each other up and down, Wherein, the workpiece holder 15 can be adjusted on the first and second longitudinal arms 13, 14, so as to meet the required height requirement.

[0021] As the technical points of the technical solution provided by the present invention: a tool suction mechanism 2 is arranged on the aforementioned first longitudinal arm 13, and the tool suction mechanism 2 includes a magnetically conductive metal plate 21 and a magnet 22, and the magnet 22 is connected to the first longitudinal The arm 13 is attracted, and the magnetically permeable metal plate 21 is attracted to the magnet 22 .

[0022] As a preferred solution, in this embodiment, a magnetically permeable seat plate 3 is fixed on the first longitudinal arm 13 through ...

Embodiment 2

[0026] The diagram is omitted, only the tool suction mechanism 2 is transferred to the aforementioned second longitudinal arm 14, and the magnet 22 is replaced with a whole magnetic plate, and the magnetic plate is attracted to the second longitudinal arm 14 for magnetic conduction. The metal plate 21 is attracted to the magnetic plate, and the magnetic base plate 3 of the first embodiment can be omitted in this embodiment, and the rest are the same as the description of the first embodiment.

Embodiment 3

[0028] The figure is omitted, the tool suction mechanism 2 is arranged on the aforementioned workpiece frame 15, and the magnet 22 is replaced with a plurality of magnetic blocks arranged at intervals from each other. Combined on the magnetic block, all the other are the same as the description of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com