Cantilever-type ink-jet printer and book placing device thereof

An inkjet printer and cantilever technology, which are applied in the field of cantilever inkjet printers and book placement devices, can solve the problems of inconsistent layout of printing content, misplacement of prefabricated forms, affecting printing quality, etc., and achieve uniform and increased text layout. The effect of using the range and improving the print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

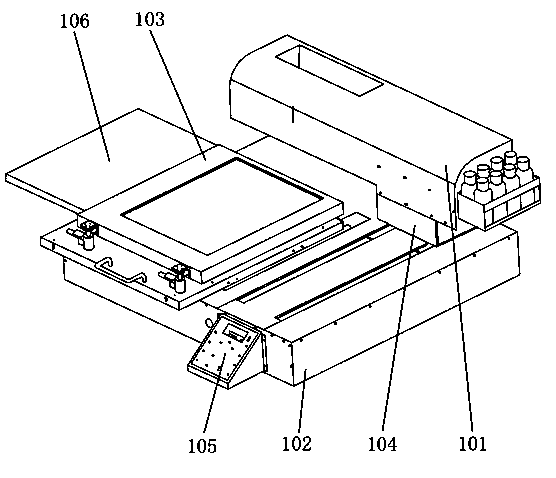

[0027] Such as figure 1 As shown, one end of the cantilever 101 is bolted to the base 104, the other end is suspended, the base 104 is slidingly connected to the base 102, and the control panel 105 is installed on the base 102;

[0028] Such as figure 2 As shown, the inkjet head 201 is connected with the motor 203 on the base 214 through the timing belt 202, moves back and forth on the guide rails 212 and 213, and is connected with the ink storage device 204 at the same time to perform X-axis printing. The base 214 and the The guide rail 206 is slidably connected with the guide rail 215, and at the same time cooperates with the screw mandrel 209 for transmission, the screw mandrel 209 is connected with the synchronous gear 205, and is driven by the motor 207 through the synchronous belt 208, driving the base 214 to slide along the guide rail 215 and the guide rail 206, so that the attached figure 1 The cantilever 101 supported on one side moves in the y-axis direction;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com