Reversing device for integrated circuit

A reversing device, integrated circuit technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of low efficiency and disadvantage, and achieve the effects of high efficiency, convenient positioning and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

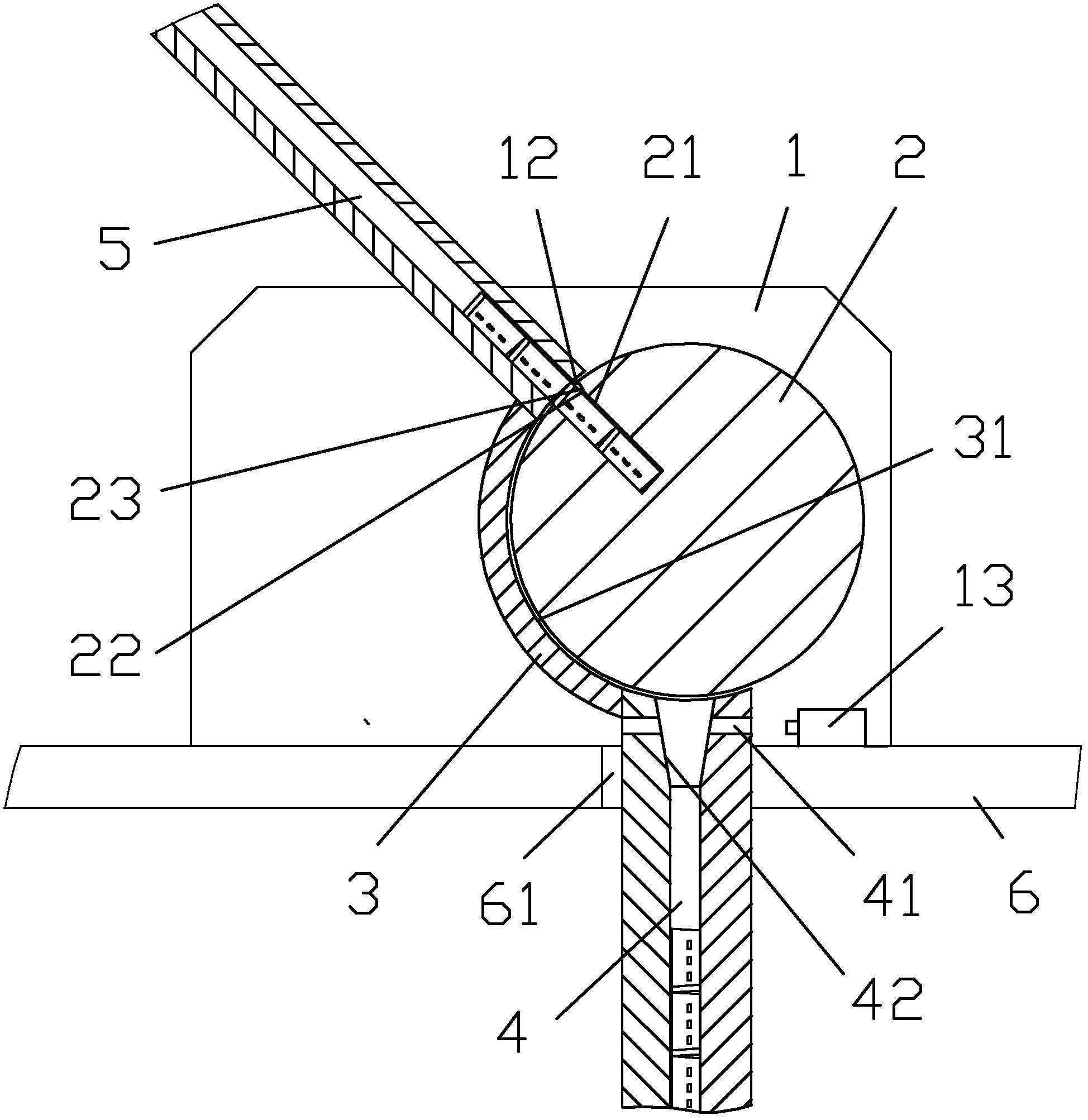

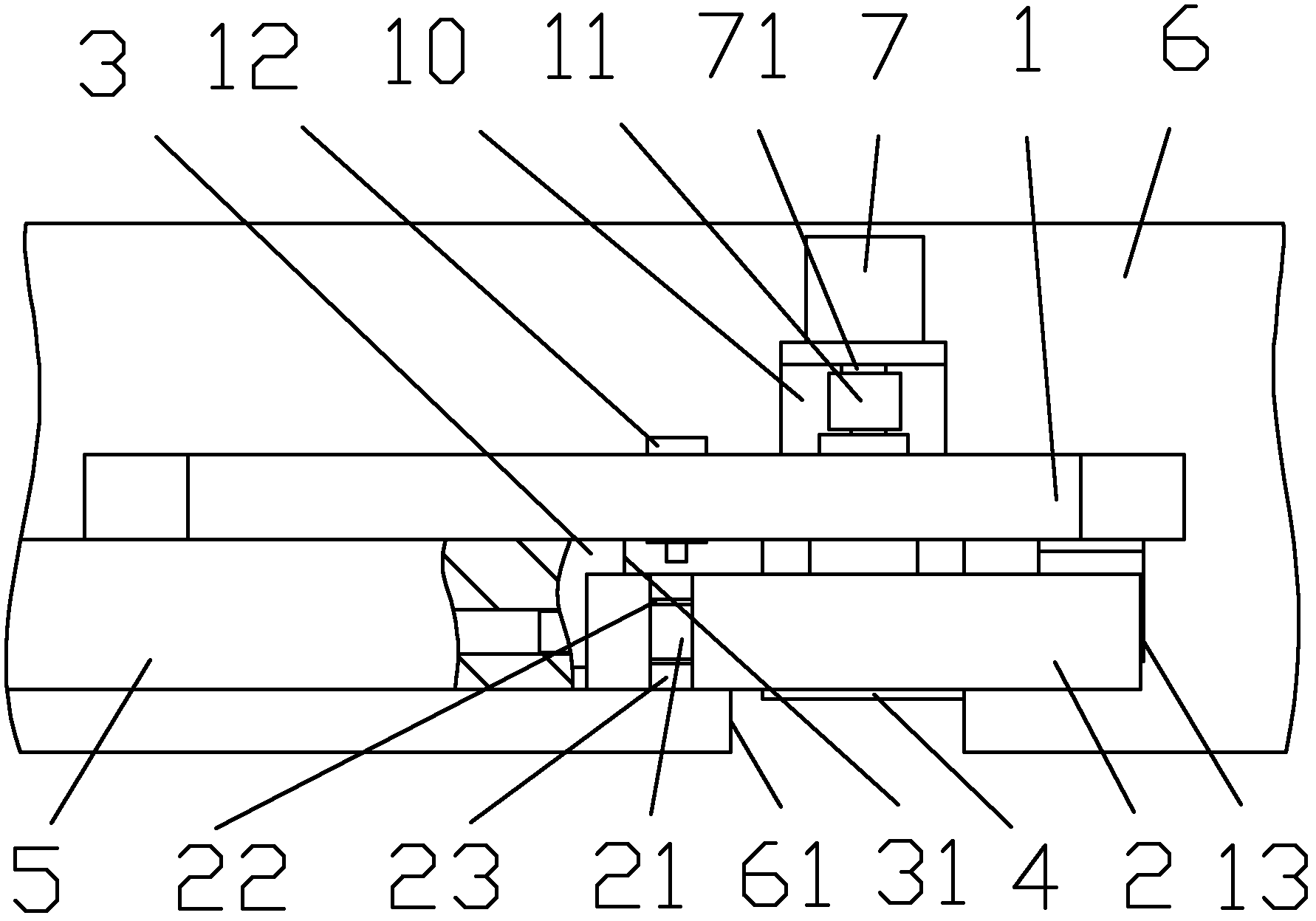

[0022] Embodiment 1, as attached figure 1 , attached figure 2 Shown: an integrated circuit reversing device, including a mounting base 1, a rotating base 2 for integrated circuit rotation and reversing, a rotating drive mechanism, and an arc-shaped stop with an arc surface 31 that fits with the outer peripheral clearance of the rotating base 2 Plate 3, discharge pipeline 4 and temporary storage pipeline 5.

[0023] The shape of the cross-section of the revolving seat 2 is circular, and the revolving seat 2 is rotationally connected with the mounting seat 1 through a bearing; The two ends of the shaped baffle 3 are in contact with one side of the discharge pipeline 4 and one side of the temporary storage pipeline 5 respectively; The inlet end of the feed conduit 4 has a guide surface 42 .

[0024] The outer circumference of the rotating base 2 has a storage groove 21, the storage groove 21 has an introduction surface 22 at the outer peripheral end of the rotating base 2, an...

Embodiment 2

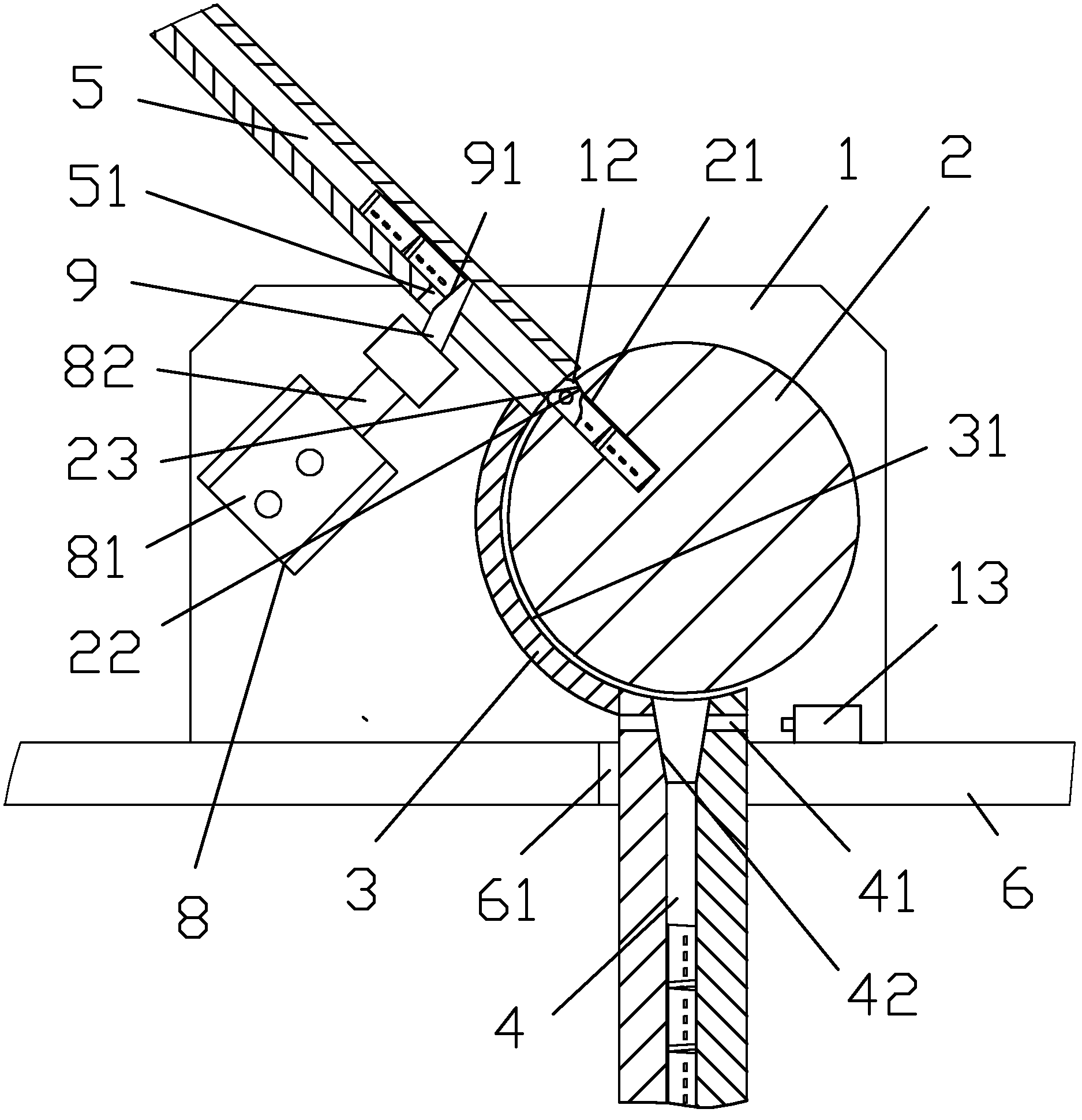

[0030] Embodiment 2, as attached image 3 , attached Figure 4 Shown: an integrated circuit reversing device, including a mounting base 1, a rotating base 2 for integrated circuit rotation and reversing, a rotating drive mechanism, and an arc-shaped stop with an arc surface 31 that fits with the outer peripheral clearance of the rotating base 2 Plate 3, discharge pipeline 4 and temporary storage pipeline 5.

[0031] The shape of the cross-section of the revolving seat 2 is circular, and the revolving seat 2 is rotatably connected with the mounting seat 1 through a bearing; , the inlet end of the discharge pipeline 4 and the outlet end of the temporary storage pipeline 5 are respectively opposite to the axis of rotation of the rotary seat 2, and the two ends of the arc-shaped baffle plate 3 are respectively connected to one side of the discharge pipeline 4 and one side of the temporary storage pipeline 5. side contact; the discharge pipe 4 , the arc baffle 3 and the temporary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com