Sewing auxiliary tool for embedding braid into clothes

An auxiliary tool and webbing technology, which is applied to sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of uneven width of decorative webbing and low efficiency of embedding decorative webbing, and achieve the effect of improving production quality and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

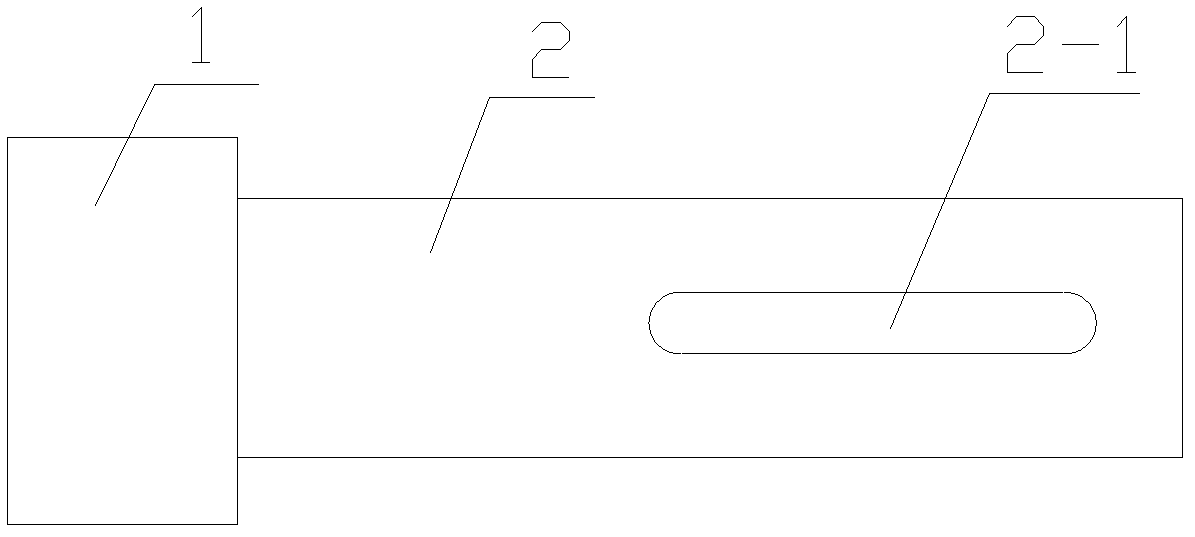

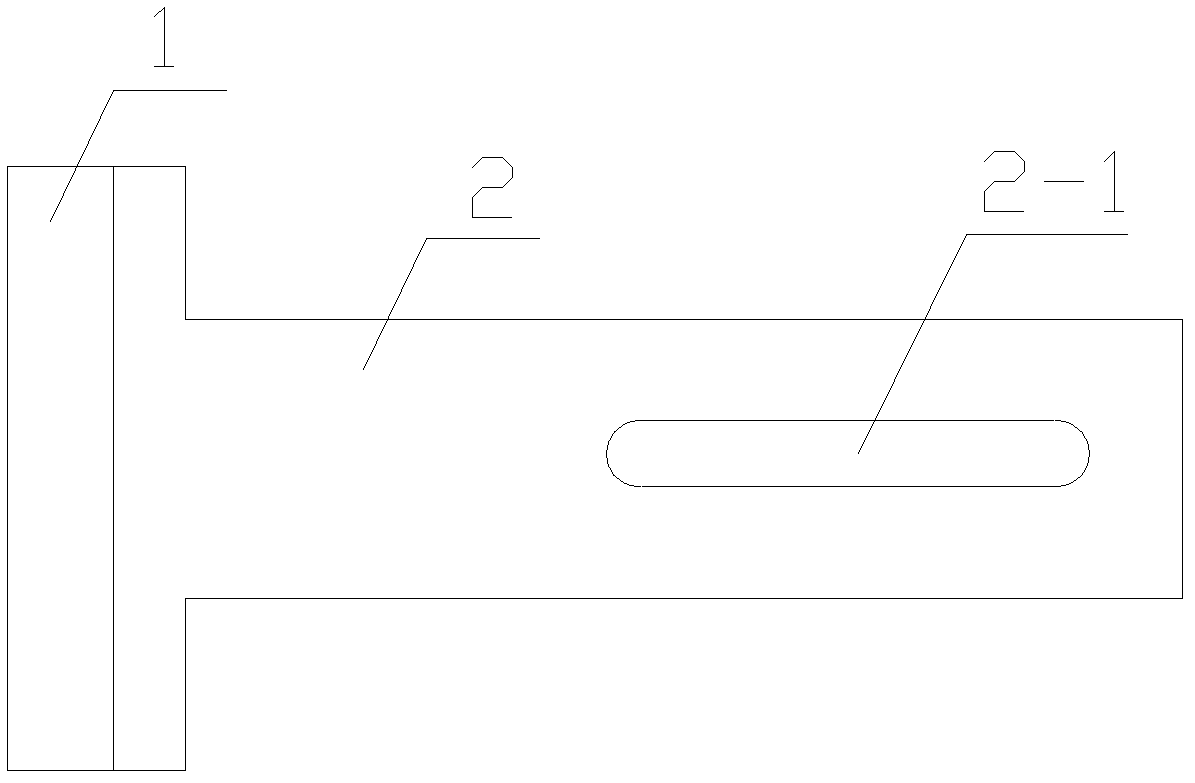

[0019] Such as figure 1 Shown is a structural schematic diagram of Embodiment 1 of the sewing auxiliary tool for embedding webbing in clothes according to the present invention. It has a tubular auxiliary part 1 for threading the webbing and a connecting plate 2 for fixing the auxiliary part 1. The connecting plate 2 is fixedly connected with the auxiliary part 1; the cross-sectional shape of the tubular auxiliary part 1 is relatively flat, which will not affect the sewing . When connecting plate 2 is placed horizontally, the bottom surface of auxiliary part 1 is higher than the bottom surface of connecting plate 2; The thickness is the same or slightly larger; the connecting plate 2 has a through hole 2-1 for fixing the connecting plate 2, and the through hole 2-1 is a waist-shaped through hole. The auxiliary part 1 and the connecting plate 2 are integrally structured.

[0020] How to use Example 1: Pass the nut through the through hole 2-1 to fix the connecting plate 2 on...

Embodiment 2

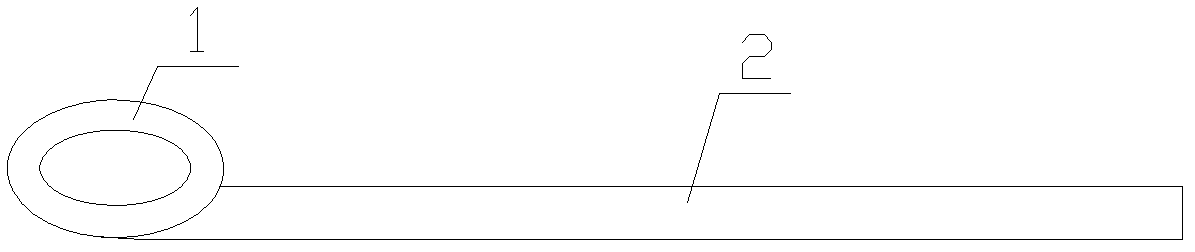

[0022] Such as figure 2 As shown, the structure schematic diagram of Embodiment 2 of the sewing auxiliary tool for embedding webbing in clothes according to the present invention. It has a tubular auxiliary part 1 for threading the webbing and a connecting plate 2 for fixing the auxiliary part 1. The connecting plate 2 is fixedly connected with the auxiliary part 1; the cross-sectional shape of the tubular auxiliary part 1 is relatively flat, which will not affect the sewing . When the connecting plate 2 is placed horizontally, the distance that the bottom surface of the auxiliary part 1 is higher than the bottom surface of the connecting plate 2 is the same as or slightly larger than the thickness of the clothes to be sewn; the connecting plate 2 has a through hole 2-1, the through hole 2-1 is a waist-shaped through hole; the tubular auxiliary part 1 has a tube connected with the hollow interior of the tubular auxiliary part 1 near the part connected to the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com