Shear yield and bending yield combined type staged soft steel damper

A mild steel damper, shear bending technology, applied in the direction of building components, shockproof, etc., can solve the problem of single energy consumption level, and achieve the effect of easy installation and replacement, small yield displacement and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

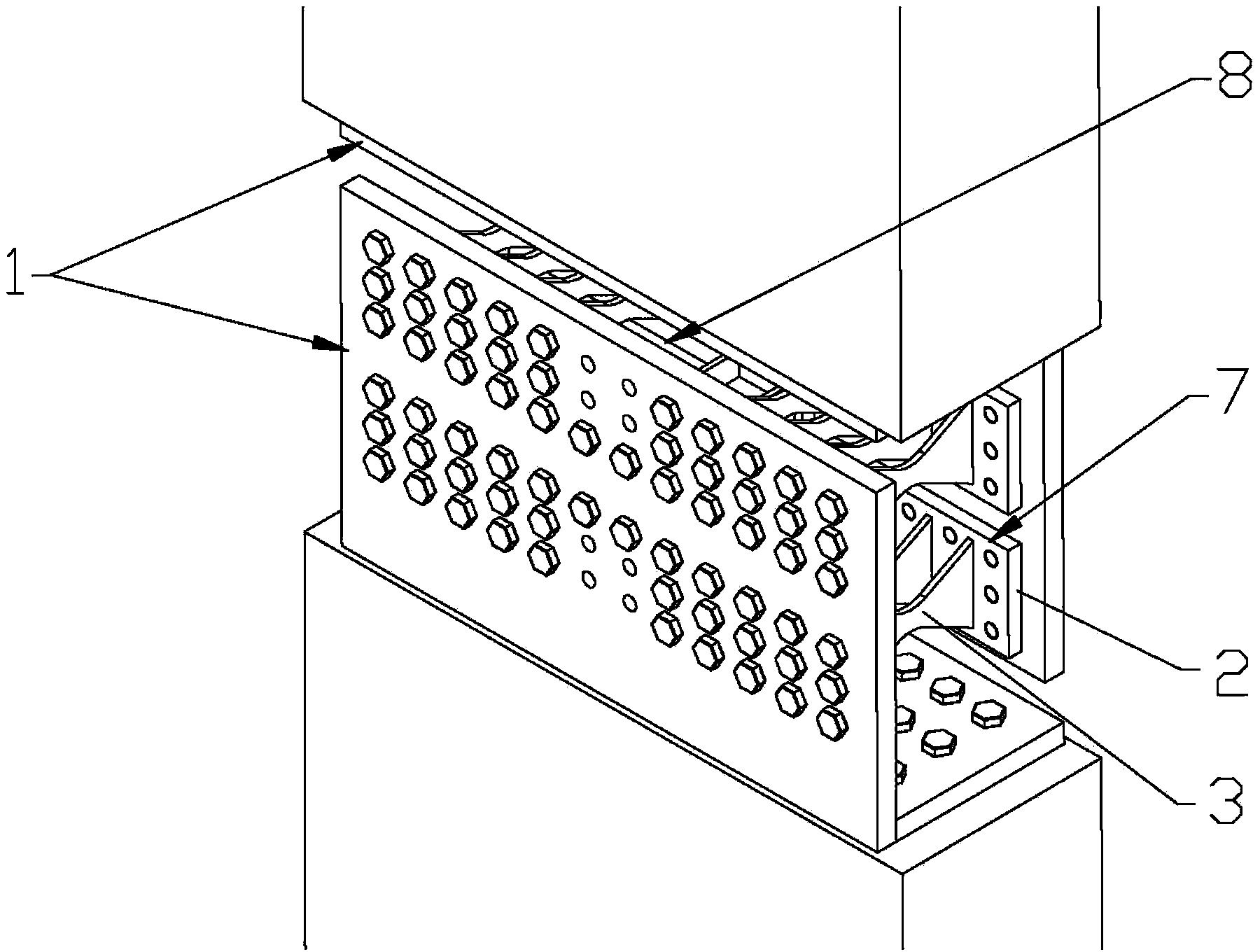

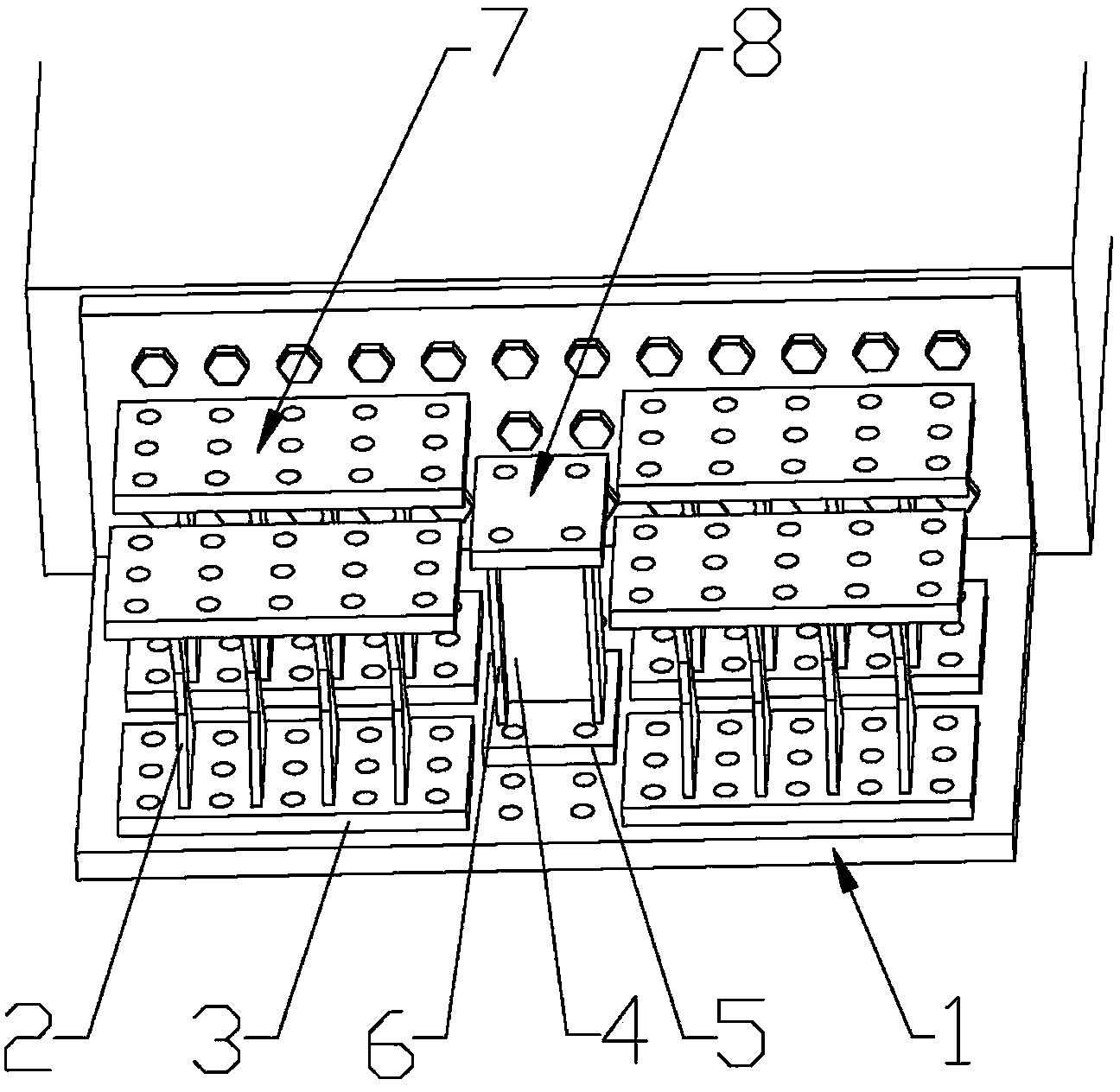

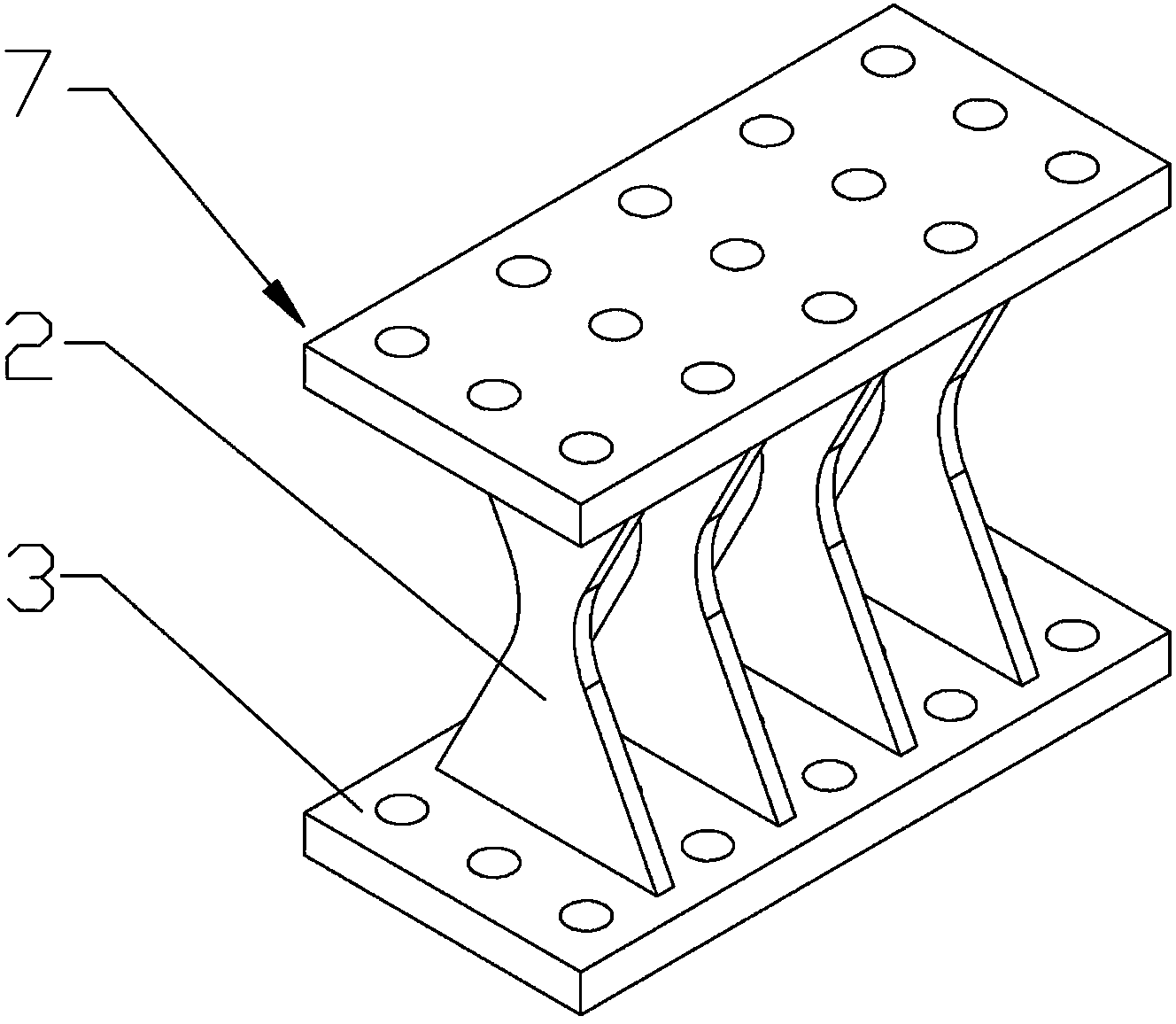

[0045] When the present invention adopts the middle column type to be installed in the building structure, such as Figure 9 As shown, several shear-bending combined staged yield mild steel dampers are combined and installed in the main structure of the building. The top horizontal plane of the L-shaped side steel plate 1 on the upper part of the combined shear-bending mild steel damper is connected to the upper main beam of the floor through high-strength bolts, and the bottom horizontal plane of the lower L-shaped side steel plate 1 is connected to the lower part of the floor through high-strength bolts. The wall support is fixedly connected. When an earthquake occurs, a relative displacement occurs between the two L-shaped side steel plates 1 in each damper. Under small earthquakes, the yield displacement of the rectangular soft steel energy-dissipating steel plate 4 is small, and the rectangular soft steel plate 4 has a small displacement. The steel energy-dissipating ste...

Embodiment 2

[0047] When the present invention adopts supporting type to be installed in the building structure, such as Figure 10 As shown, several shear-bending combined staged yield mild steel dampers are combined and installed in the main structure of the building. The top horizontal plane of the L-shaped side steel plate 1 on the upper part of the combined shear-bending mild steel damper is connected to the upper main beam of the floor through high-strength bolts, and the bottom horizontal plane of the lower L-shaped side steel plate 1 is connected to the main beam of the lower floor through high-strength bolts. The herringbone steel supports set on the beams are fixedly connected, and the supports act as fixed dampers. When an earthquake occurs, a relative displacement occurs between the two L-shaped side steel plates 1 in each damper. Under small earthquakes, the yield displacement of the rectangular soft steel energy-dissipating steel plate 4 is small, and the rectangular soft ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com