Core energy dissipation structure with enhanced ductility and buckling-restrained energy dissipation support

An anti-buckling energy-dissipating and core technology, which is applied in the direction of earthquake resistance, building components, building types, etc., can solve the problem of weakening the energy-dissipating effect of anti-buckling energy-dissipating supports, limited protection, and the degree of work hardening of Fe-Mn-Si alloys Advanced problems, to achieve the effect of good ductility and cumulative plastic deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

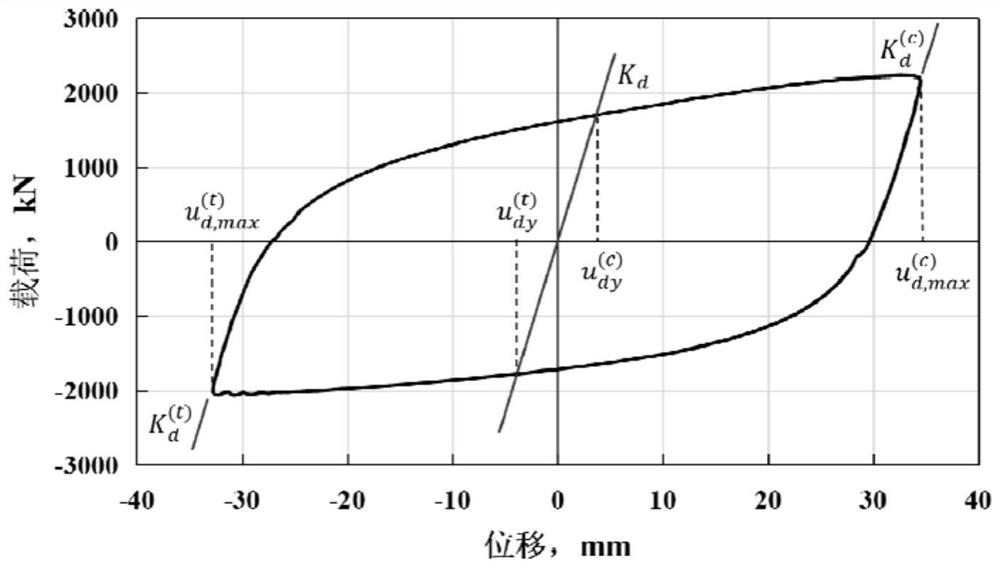

[0064] A buckling-resistant energy-dissipating brace with enhanced ductility, consisting of a core energy-dissipating structure and peripheral constraining members.

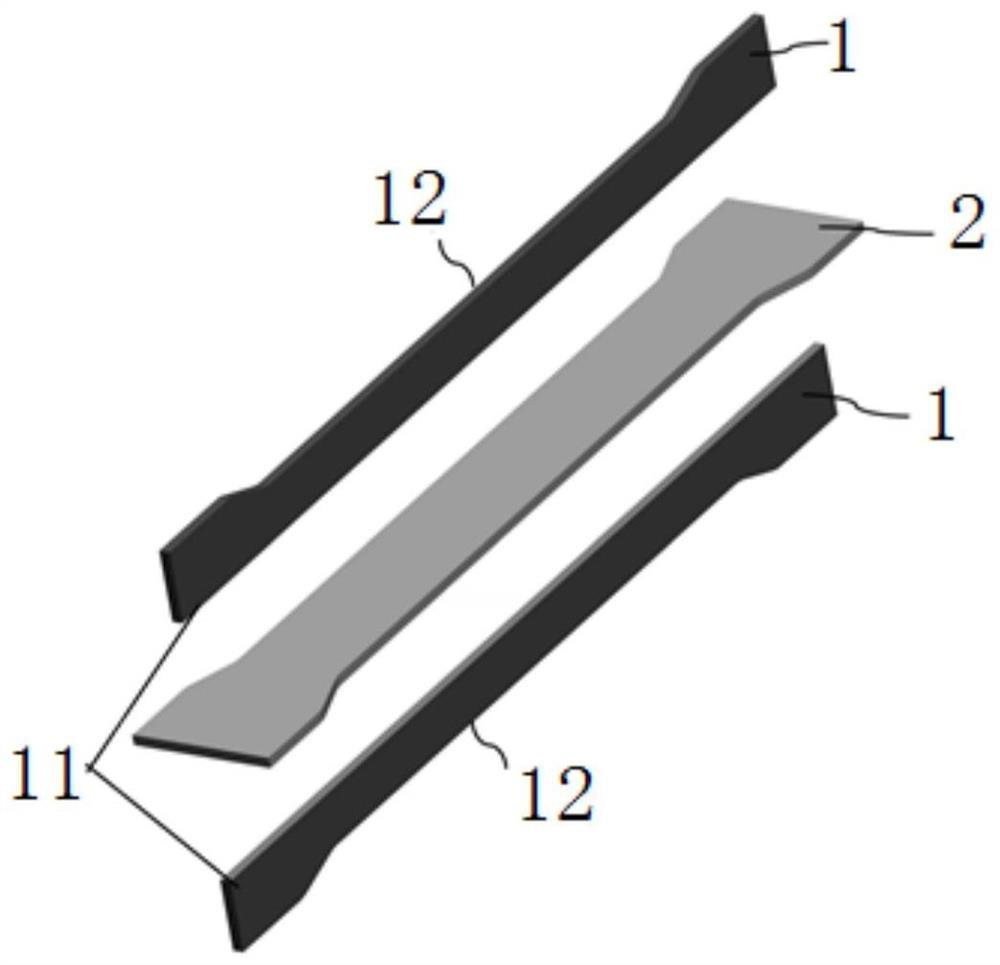

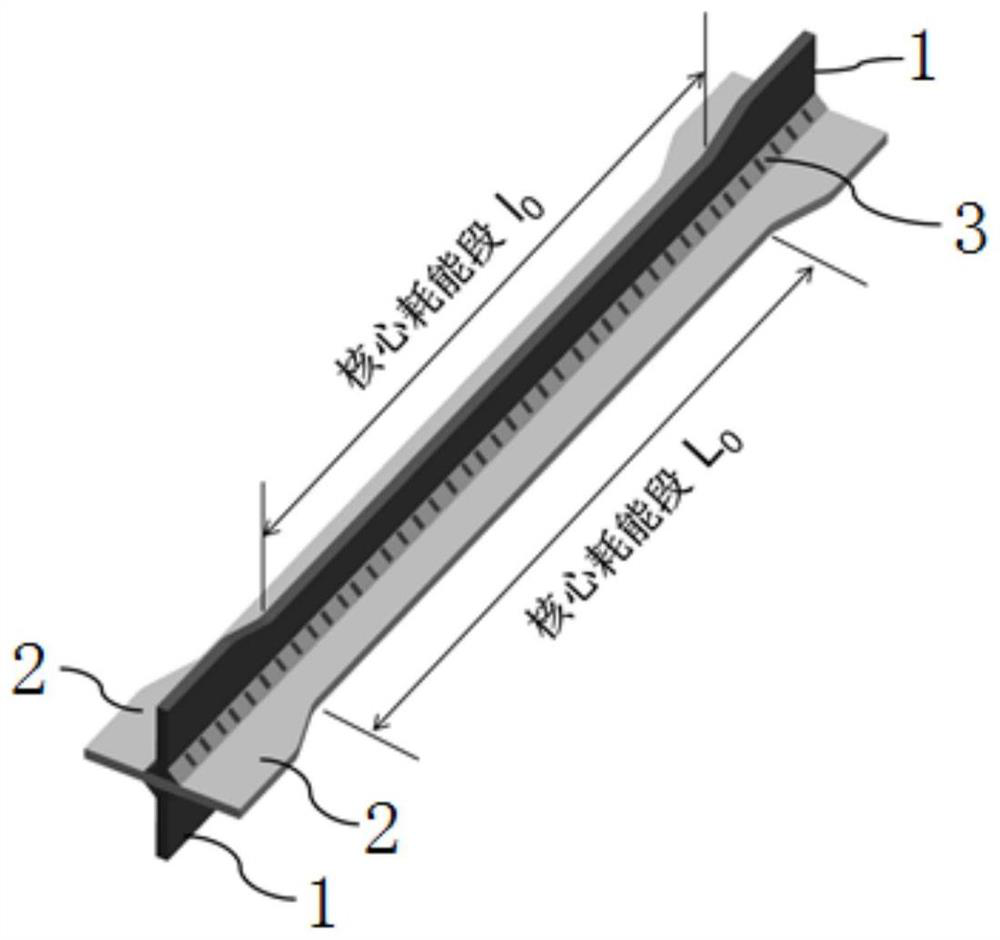

[0065] The cross-section of the core energy-dissipating structure has a cross-shaped axisymmetric geometry, and its symmetry axis is the axial direction of the energy-dissipating support. The cross-section is narrow in the middle and wide at both ends along the axial direction. like figure 2 and image 3 As shown, the core energy-dissipating structure is composed of one austenitic steel plate 2 and two ferritic steel plates 1, the austenitic steel plate 2 and the ferritic steel plate 1 have the same longitudinal length; the two ferrite steel plates Steel plates 1 with ferritic structure are respectively placed above and below steel plate 2 with austenitic structure, taking the longitudinal centerline of steel plate 2 with austenitic structure as the axis of symmetry; Closely connected by welding, the weld 3 is...

Embodiment 2

[0078] A buckling-resistant energy-dissipating brace with enhanced ductility, consisting of a core energy-dissipating structure and peripheral constraining members.

[0079] The geometric shape and connection method of the core energy dissipation structure of the buckling-resistant energy-dissipating brace described in this embodiment are exactly the same as those of the core energy-dissipating structure of the buckling-resistant energy-dissipating brace described in Embodiment 1.

[0080] In this embodiment, the chemical composition and mass percentages of the austenitic steel plate forming the core energy dissipation structure are: 29.4% Mn, 4.3% Si, 1.4% Al, 0.049% C, 0.009% P, 0.008% S, 0.005% N, the rest is Fe and unavoidable impurity elements. The average austenite grain size of the austenitic structure steel plate is 76 μm. The yield strength of the austenitic steel plate is 304 MPa, and the elongation at break is 52%. The microstructure of the austenitic structure st...

Embodiment 3

[0087] A buckling-resistant energy-dissipating brace with enhanced ductility, consisting of a core energy-dissipating structure and peripheral constraining members.

[0088] The cross-section of the core energy-dissipating structure has a cross-shaped axisymmetric geometry, and its symmetry axis is the axial direction of the energy-dissipating support. The cross-section is narrow in the middle and wide at both ends along the axial direction. Specifically, the core energy-dissipating structure is composed of one austenitic steel plate and two ferritic steel plates. The lengths of the austenitic steel plate and the ferritic steel plate are the same in the longitudinal direction; and connect as figure 2 and image 3 shown.

[0089] The geometric shape of the austenitic steel plate forming the core energy-dissipating structure is as follows: Figure 4 shown. The total length of the austenitic steel plate L=2000mm; the length L of the central part of the steel plate 0 =1430mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com