A Lead Shear Energy Dissipator with Position Limiting Function

An energy-consuming device and functional technology, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems of no limit function, small binding force of lead body, and single energy consumption form, so as to achieve easy standardization of standardized parameter design and high energy consumption , the effect of stable energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

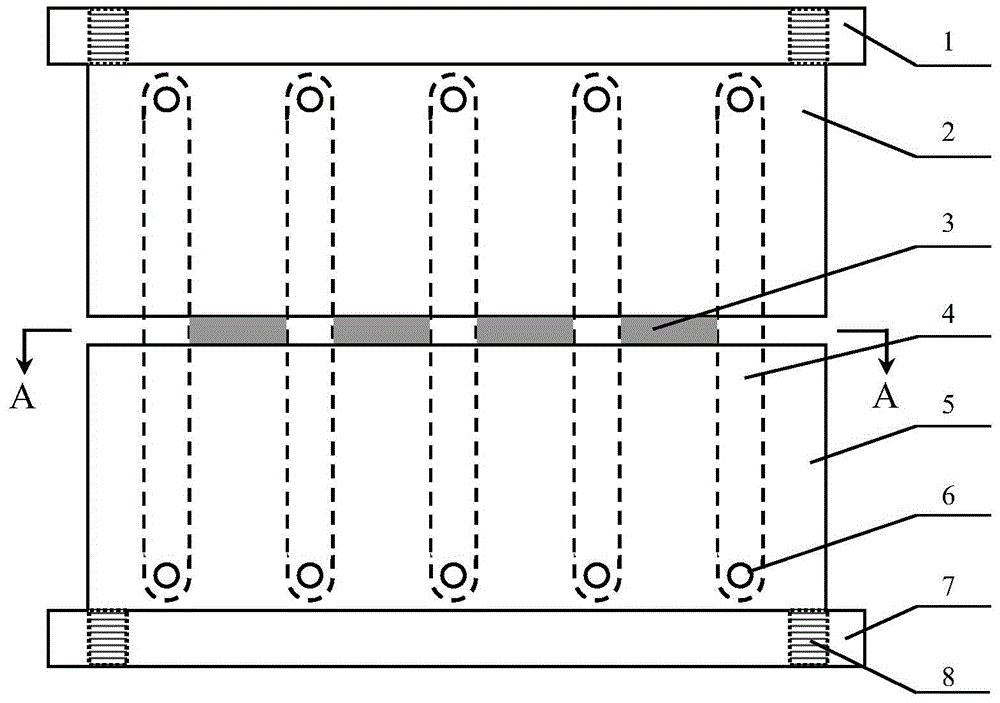

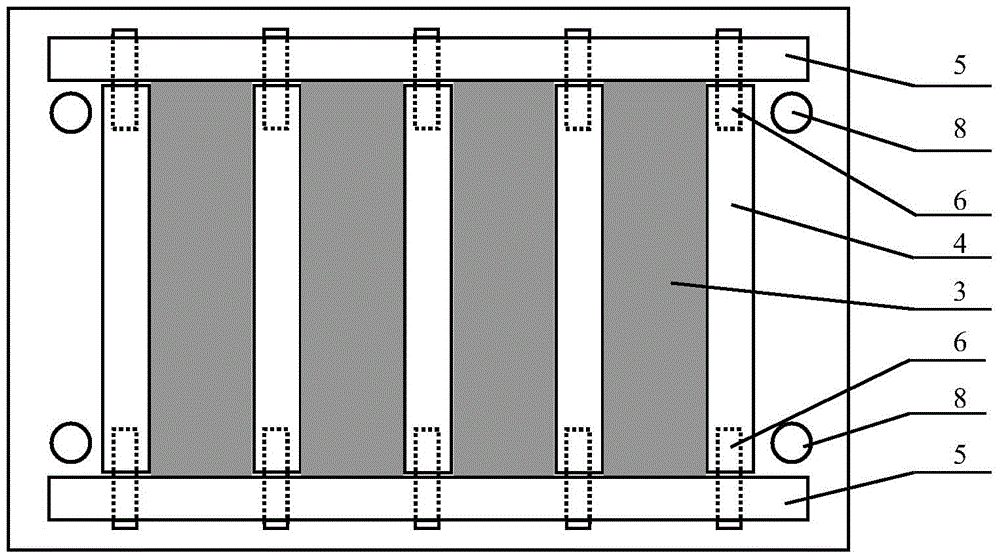

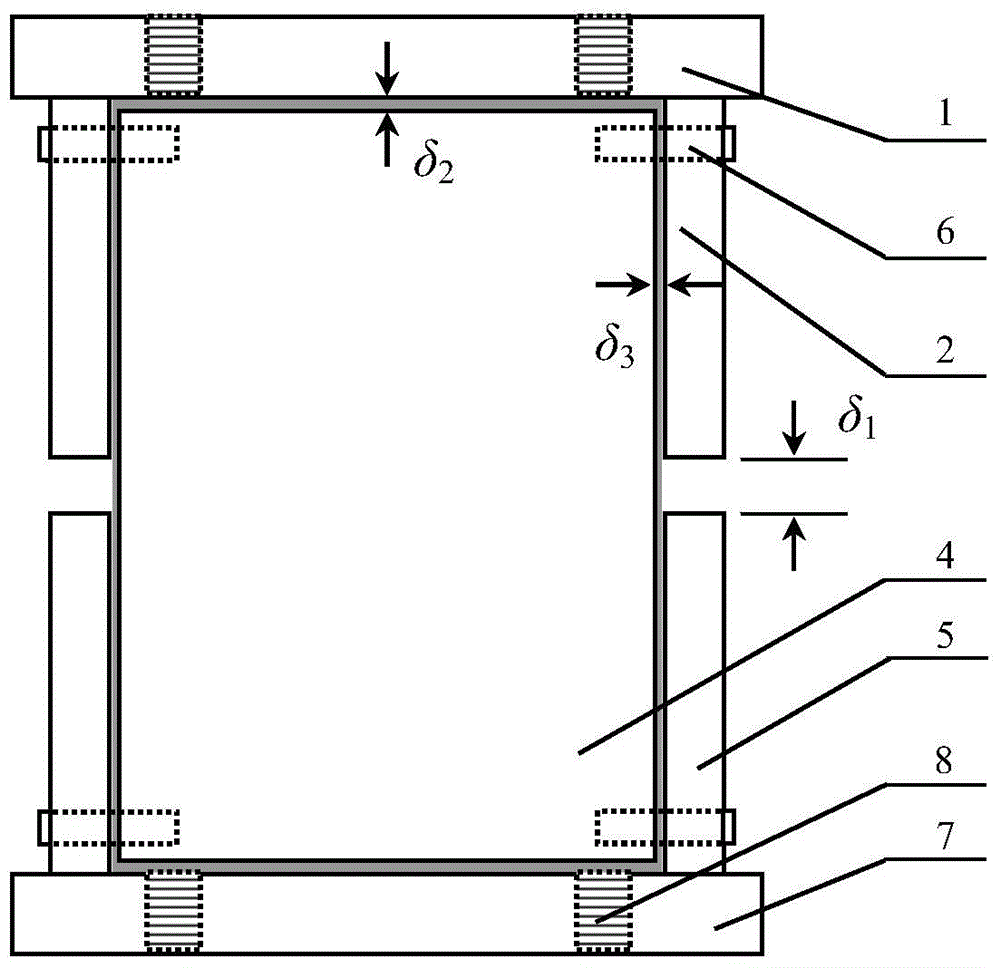

[0023] exist figure 1 , figure 2 and image 3 In the schematic diagram of the lead shear energy dissipator with limit function shown, the upper cover plate 1 and the lower cover plate 7 are steel plates with a size of 200*100*12mm, and Φ16 The connecting bolt holes 8 are used to connect with the main structure; an upper side baffle 2 is respectively arranged on both sides of the upper cover plate, and a lower side baffle 5 is respectively arranged on both sides of the lower cover plate, four side baffles The plate is a steel plate with a size of 38*120*12mm, and there is a gap δ between the upper and lower side baffles 1 4mm; one end of each upper and lower side baffle near the upper and lower cover is 10mm away from the end of the cover, and a Φ6 through pin hole is set every 27mm at a distance, and each upper and lower side baffle is welded at a distance from the cover. 9 mm from the edge; five rectangular partitions 4 are arranged between the upper cover and the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com