Moveable combination of guide rod and milling cone

A guide rod and movable technology, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems that the success rate of casing cannot be guaranteed and the construction of overhaul is complicated, so as to prevent axial series movement and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

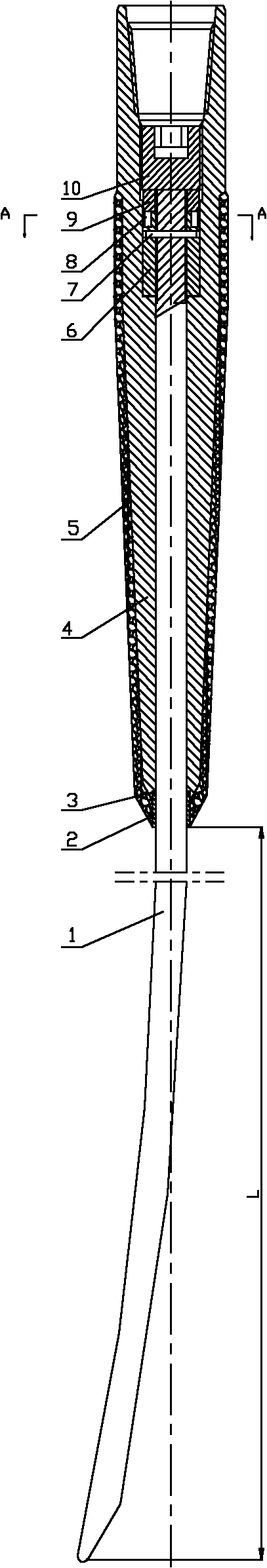

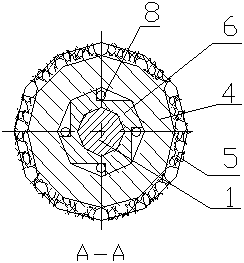

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] Depend on figure 1 As shown, the movable guide rod milling cone is connected to the lower end of the workover drill string, and after finding the channel of the dislocation of the casing, it is milled and expanded. The movable guide rod milling cone includes a guide rod 1 and a milling cone body 4 with a stepped hole. The stepped hole of the milling cone body 4 has a built-in limit ring 9, a plug 10, an orientation joint 6 and a pin shaft 7, wherein the The lower section of the guide rod 1 is curved, and the lower end is wedge-shaped, which is beneficial for inserting into the remaining channel at the dislocation of the casing. The upper section of the guide rod 1 is a straight rod and placed in the center hole of the milling cone 4. The upper part of the straight rod The external thread section is threadedly connected with the directional joint 6 and the limit ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com