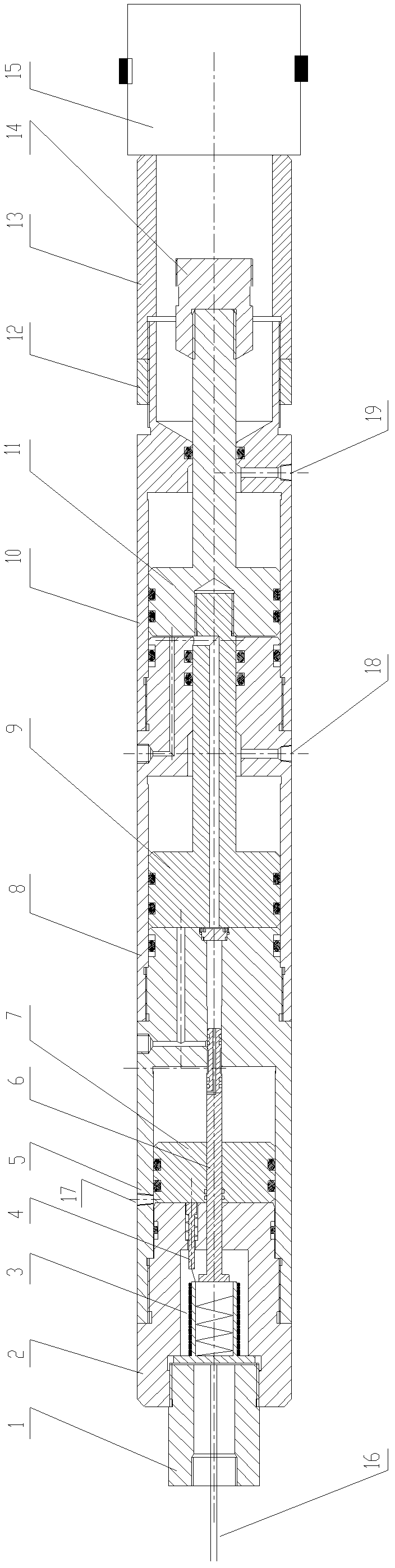

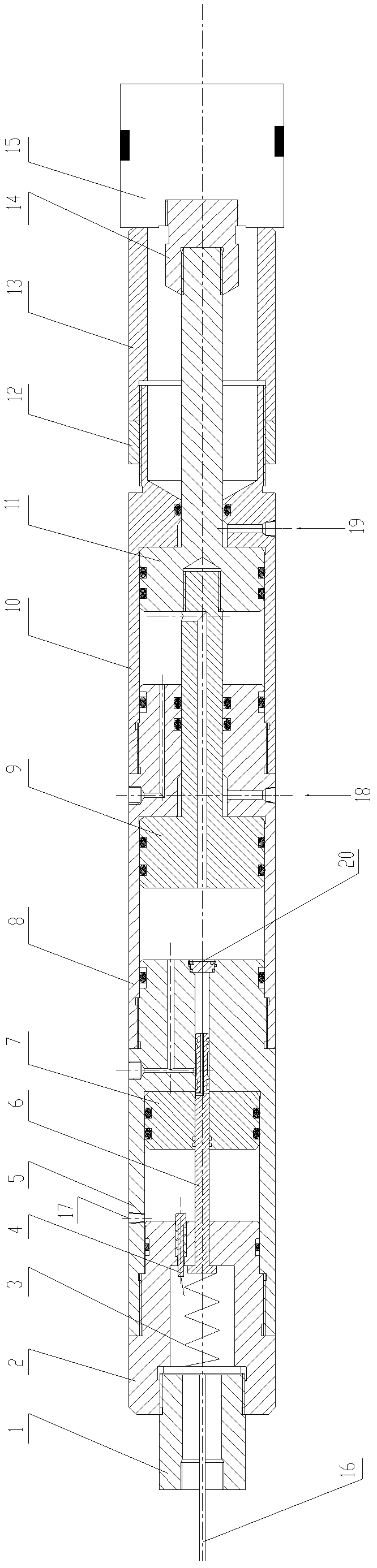

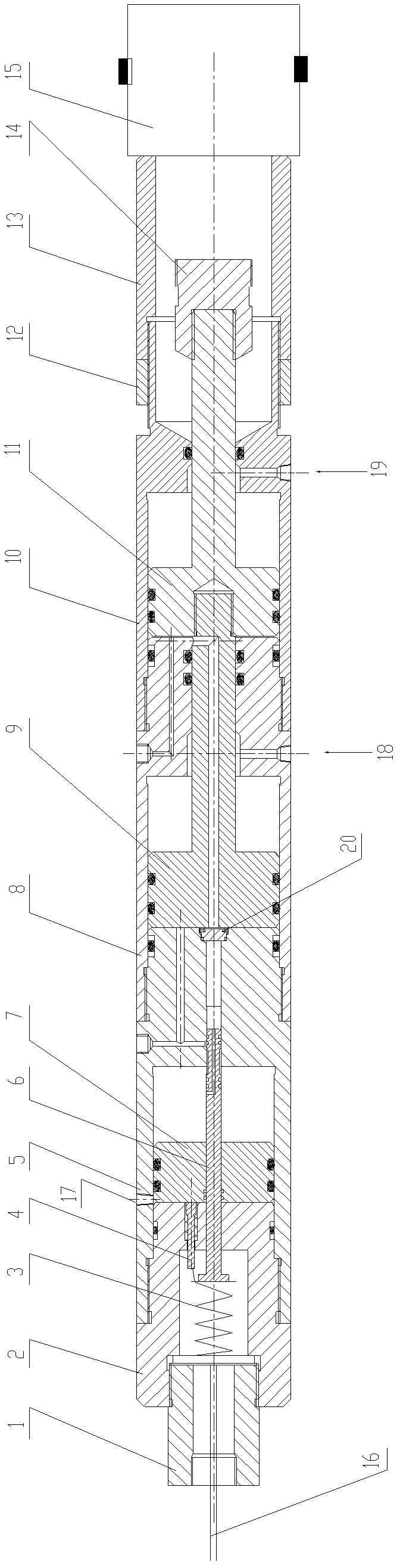

Method for running bridge plug sitting tool by means of differential pressure and bridge plug sitting tool utilized by same

A bridge plug seat and tool seat technology, which is applied in the field of bridge plug seat sealing tools, can solve the problems of damage to perforating equipment, large vibration, etc., and achieve the effects of overcoming large vibration, convenient operation, and simple tool structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of using the pressure difference to use the bridge plug setting tool to set the seal, the specific steps are as follows:

[0024] 1) Open the oil cavity channel of the bridge plug seating tool, and the annular liquid enters the middle outer cylinder and the lower outer cylinder of the bridge plug seating tool from the liquid inlet of the bridge plug seating tool,

[0025] 2) The pressure difference between the incoming liquid and the air chamber drives the piston upward, and the upward movement of the piston drives the bridge plug connector to move upward. The bridge plug connector is connected to the center rod of the bridge plug, and the bridge plug center rod moves upward to compress the bridge plug seat seal. pieces to seal the bridge plug,

[0026] 3) After the bridge plug is seated, the piston continues to move upward until the bridge plug connection joint is separated from the center rod of the bridge plug, and the bridge plug is dropped.

[0027] 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com