Dual-valve flow-equalizing device for air exhaust

A technology of exhaust pipe and valve body, applied in the field of double-valve exhaust air equalization device, to achieve reliable action, fine adjustment and self-locking, and eliminate noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

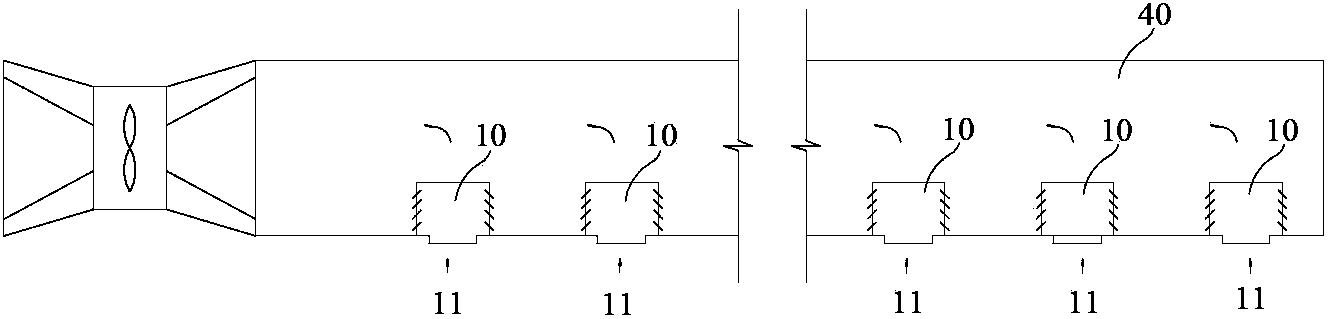

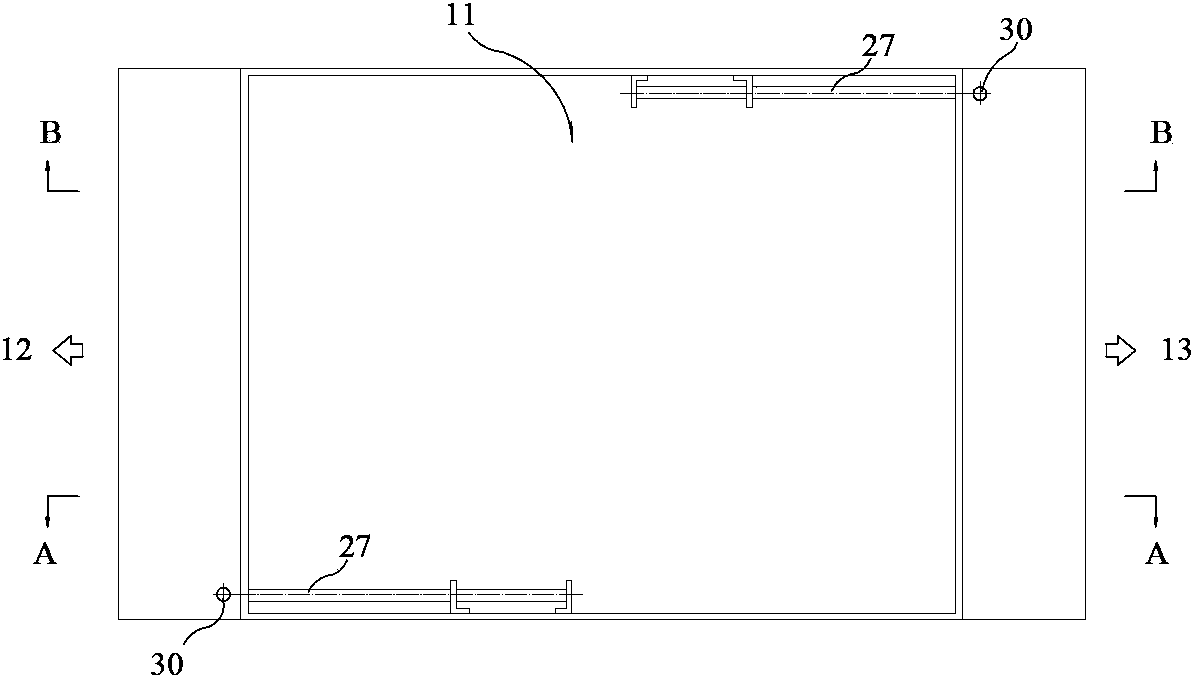

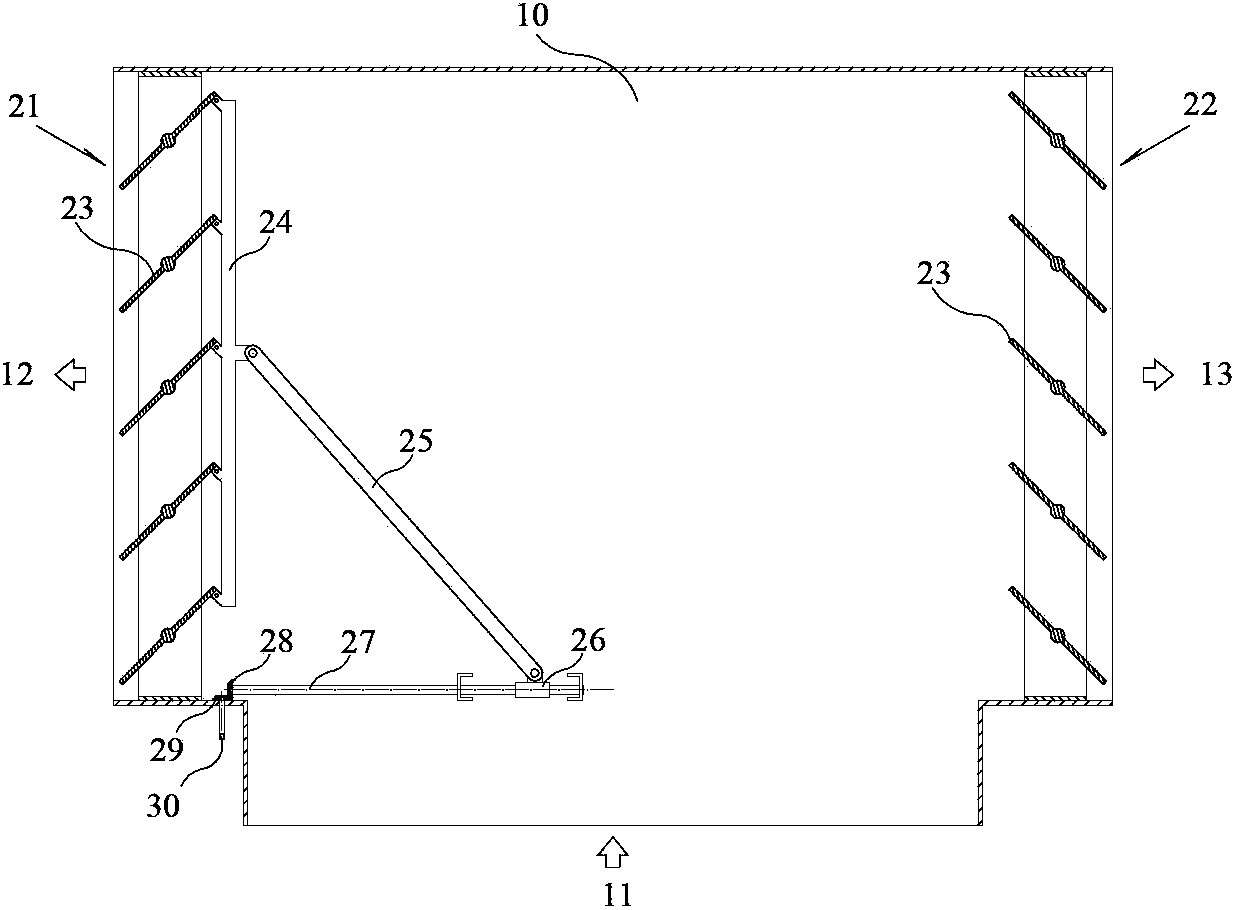

[0019] refer to figure 1 , figure 2 , image 3 and Figure 4 , the dual-valve exhaust flow equalization device of the present invention includes shell-shaped valve bodies 10 arranged at intervals along the extending direction of the exhaust duct 40, and the bottom of the shell-shaped valve body 10 has an air inlet 11 communicating with the outer space of the exhaust duct. The shell-shaped valve body 10 is provided with a near-end tuyere 12 and a far-end tuyere 13 on both side walls along the direction in which the exhaust duct extends, and a near-end air valve 21 is respectively arranged on the near-end tuyere 12 and the far-end tuyere 13. , The remote air valve 22, the proximal air valve 21, and the remote air valve 22 have independent opening adjustment mechanisms.

[0020] refer to figure 1 , each shell-shaped valve body 10 is provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com