Telescopic parallel pull rod type device used for measuring spatial six-degree-of-freedom motion

A telescopic pull rod and degree of freedom technology, applied in measuring devices, instruments, etc., can solve the problems of environmental error, frequency response and integral error error, broken pull wire, etc., to reduce additional force and additional mass, strong impact resistance, Rotating flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

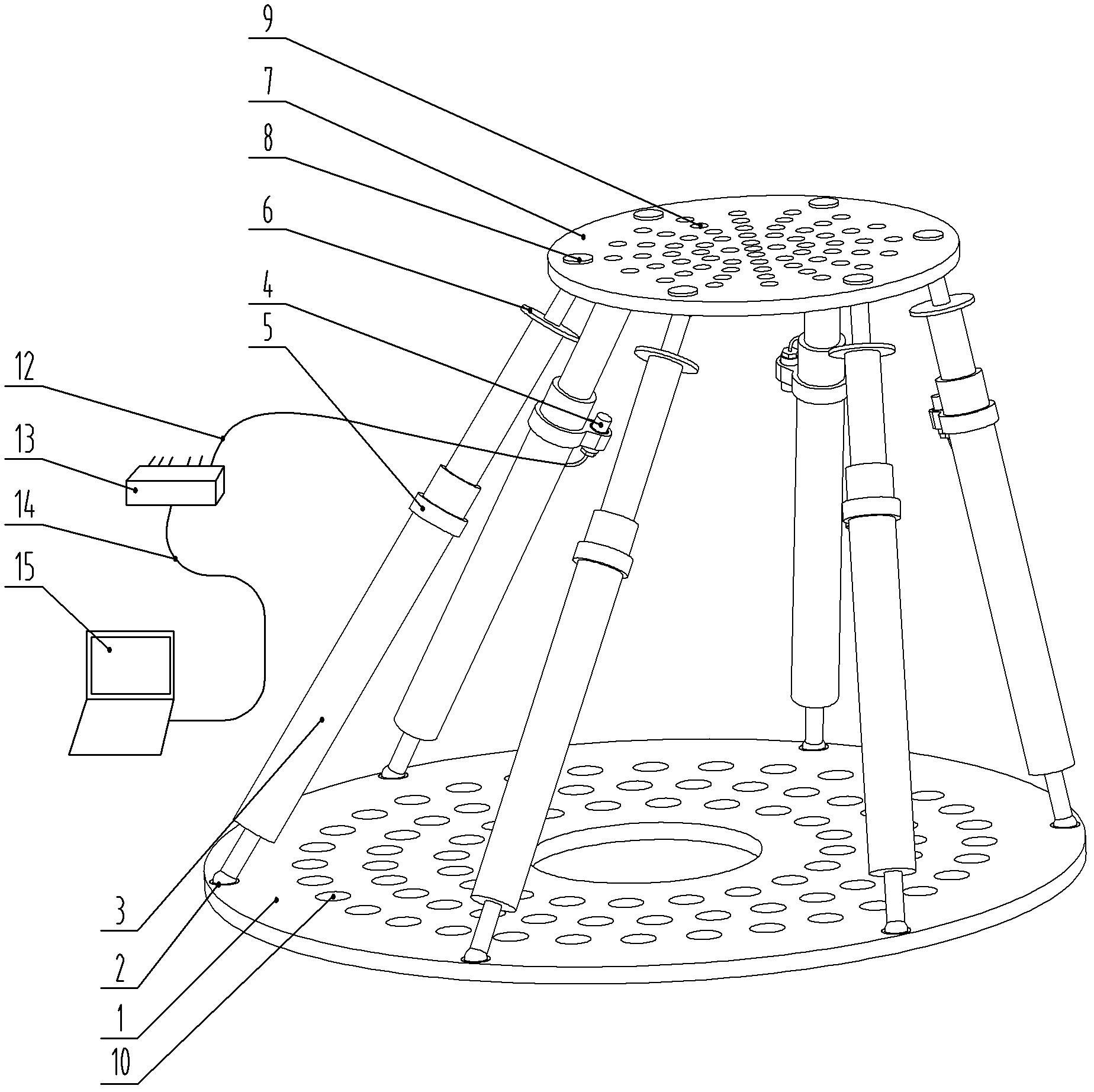

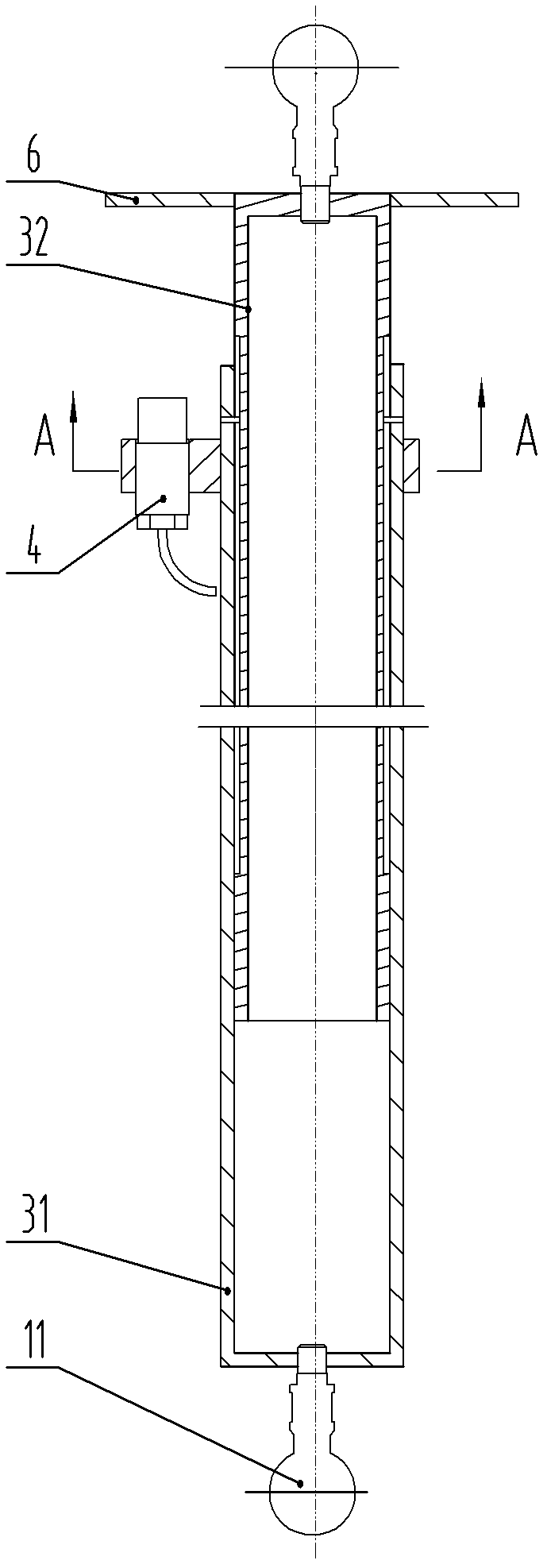

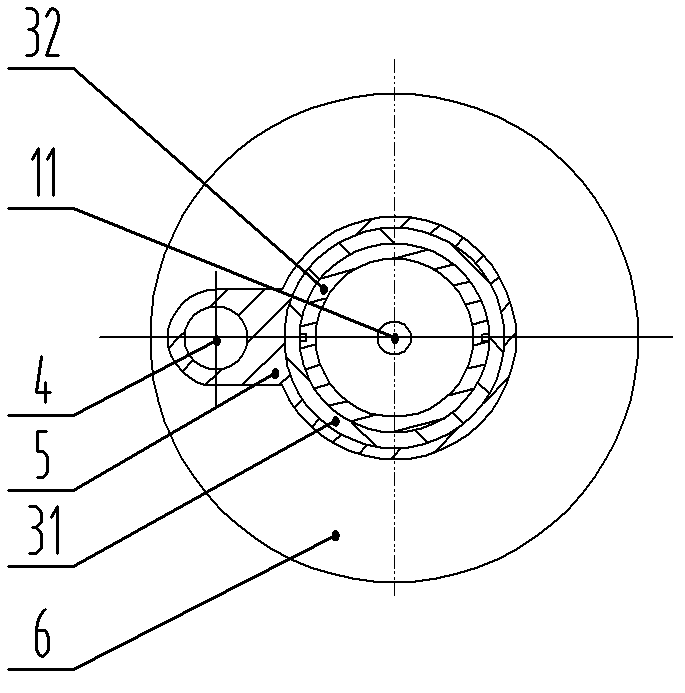

[0030] Such as figure 1 As shown, the fixed platform 1 is a flat plate structure, and six lower spherical hinges 2 are installed on the fixed platform 1. These six lower spherical hinges 2 form a ring, and the six lower spherical hinges 2 are divided into three on the left and three on the right. The lower spherical hinges 2 on the left and right sides are distributed symmetrically. The fixed platform 1 is preferably circular or regular hexagonal. When the fixed platform 1 is circular, the lower ball hinge 2 is preferably evenly distributed on the fixed platform 1 by the circumference; when the fixed platform 1 is a regular hexagon, the lower spherical hinge 2 2 are preferably distributed at the six corners of a regular hexagon. A moving platform 7 is arranged above the fixed platform 1, the shape of the moving platform 7 is the same as that of the fixed platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com