Compressive stress loading and deformation measurement device and measurement method for deformation of test piece under compressive stress

A measuring device and compressive stress technology, which is applied in the direction of measuring the deformation of mechanical solids and using stable tension/pressure to test the strength of materials, etc., can solve the problems of not being able to realize the measurement of deformation loading devices, etc., to facilitate analysis and research, and function Variety and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A typical operation process is as follows:

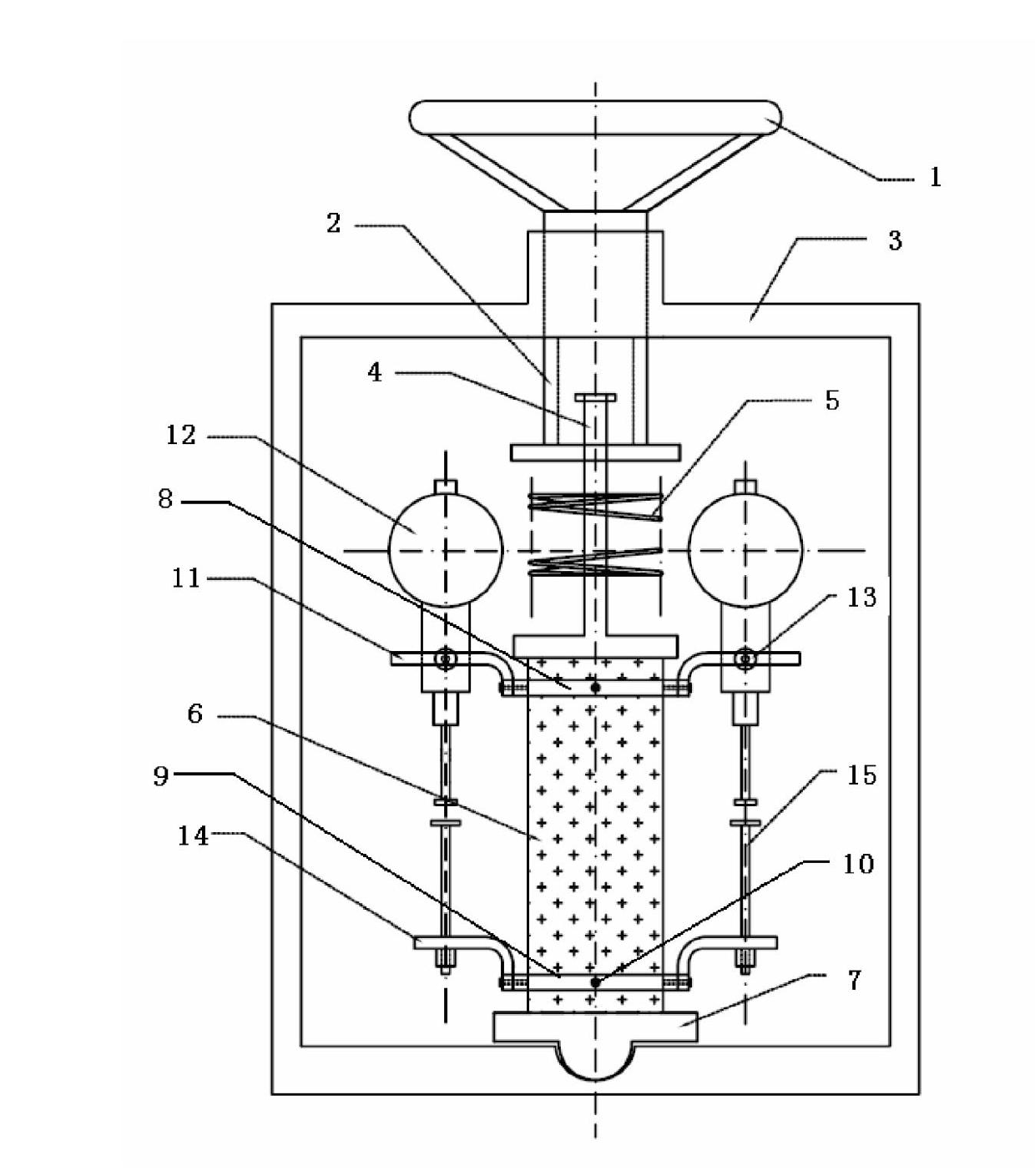

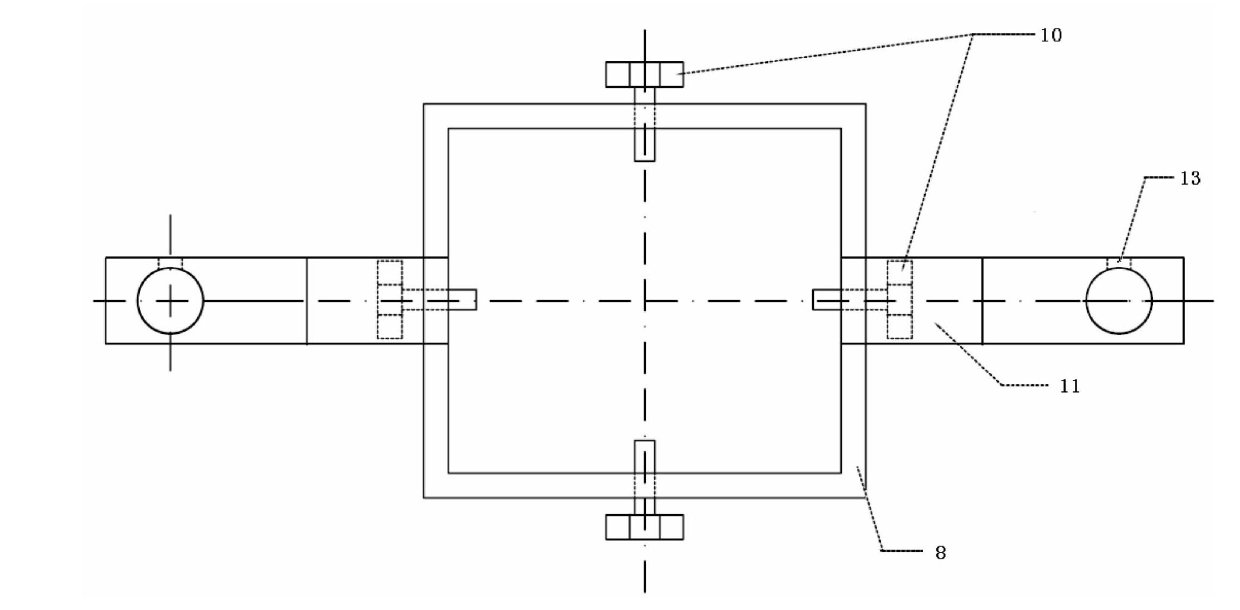

[0040] The first step: set the upper fixture 8 on the upper part of the test piece 6, fix it on the test piece 6 with four positioning bolts 10, and keep the upper fixture 8 perpendicular to the test piece 6; set the lower fixture 9 on the test piece 6 At the lower end, tighten the positioning bolt 10, and keep the lower fixture 9 perpendicular to the test piece 6.

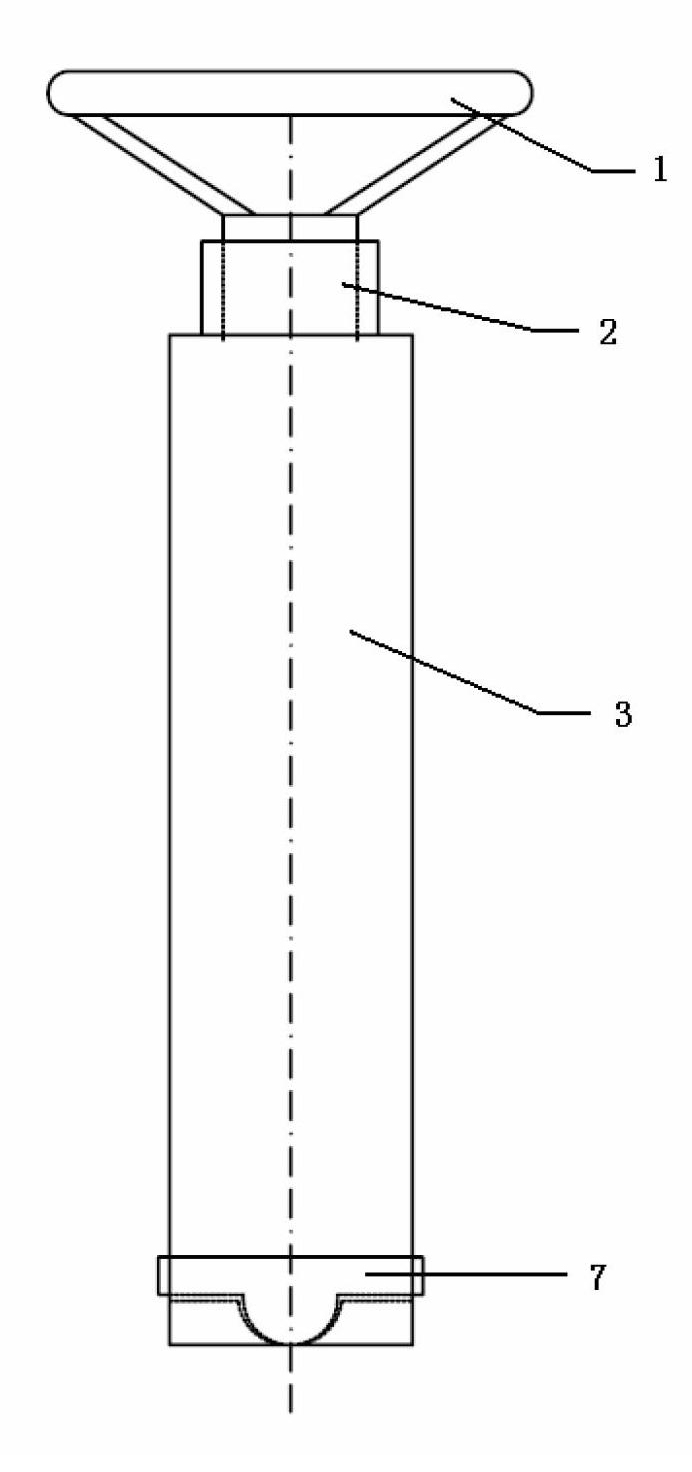

[0041] The second step: place the hemispherical end of the pressure joint 7 in the hemispherical concave shape of the frame 3, place the test piece 6 that has completed the first step on the pressure joint 7, and place the bottom end of the slide bar 4 on the flat plate Facing the test piece 6, rotate the handwheel 1 to compress the compression spring 5 to ensure that the centerlines of the slide bar 4, the test piece 6 and the pressure joint 7 coincide as much as possible, and continue to rotate the handwheel 1 to compress the compression spring 5 to the set val...

Embodiment 2

[0044] Place the test piece 6 that has completed Example 1 together with the loading device under the environmental effects of corrosive solution, dry-wet cycle, water dissolution, carbonization, etc., and coat the lower clamp 9, the adjusting bolt 15, and the measuring head of the dial indicator 12. Put vaseline on it to keep it from corroding. At this point, the deformation of the specimen under the coupling effect of compressive stress and environment can be measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com