Forming method for light bar circuit board

A molding method and circuit board technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of excessive V-cut, affecting product quality, abnormal intermediate board width, etc., to ensure product quality and less difficult to operate. , The effect of improving the yield of finished boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

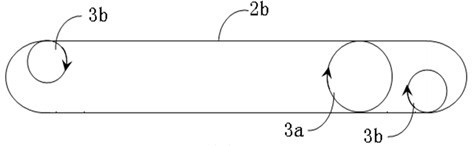

[0026] Such as Figure 4 , 5 , 6, this embodiment discloses a Light bar circuit board molding method, including the following steps:

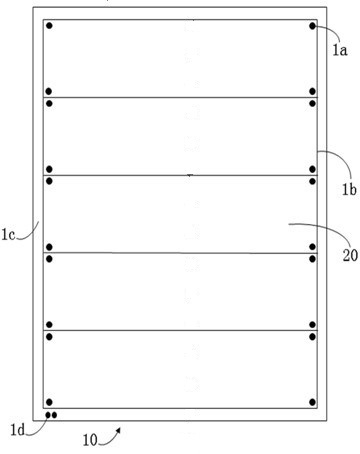

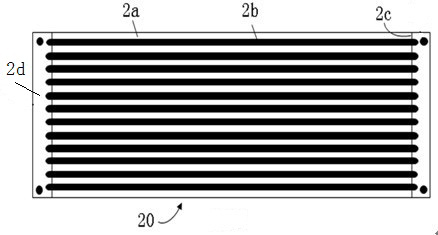

[0027] Step one, design molding line 4b on the PNL board 40 to be formed, design five set boards 50 within the molding line 4b, and be provided with positioning holes 4a and outside the PNL board molding line at the four corners of each set board The frame bar at the bottom of the forming outer frame 4c is provided with two direction holes 4d, plant the positioning PIN according to the position of the positioning holes on the molding machine, and put the PNL board on the positioning PIN according to the direction indicated by the direction hole 4d;

[0028] Step 2: Use a forming machine to drill thirteen fixing holes 4e on the top frame bar of the forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com