Self-cleaning dust collection device

A dust collection and self-cleaning technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and the filtration of dispersed particles, etc., can solve the problems of clogged filter bags and affect the normal operation of dust filter equipment, so as to prevent clogging and bridging and prolong service life life, and the effect of avoiding secondary cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

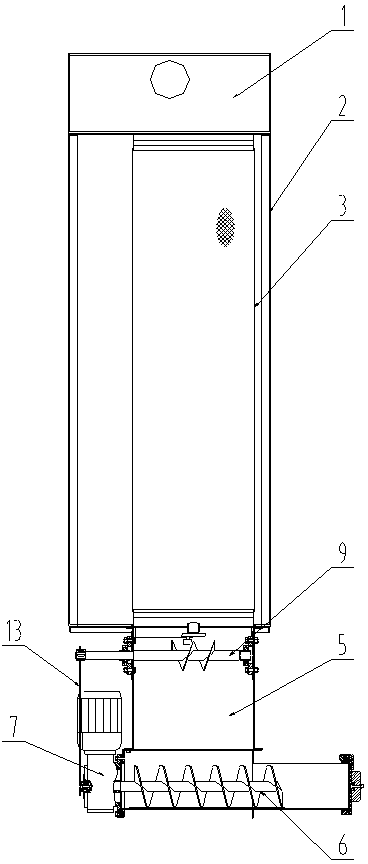

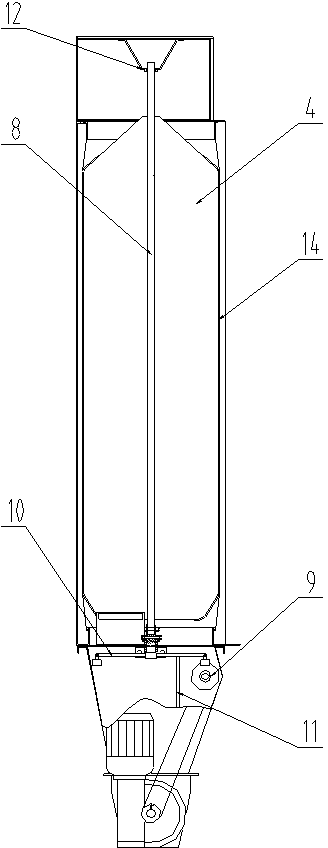

[0030] see figure 1 , figure 2 , The present invention relates to a self-cleaning dust collection device, which includes an air inlet box 1, a coaming plate 2, a filter bag 3, a scraper 4, an ash hopper 5, a dust compactor 6 and a pressing reduction motor 7. The filter The bag 3 is provided with a scraper shaft 8, the scraper 4 is mounted on the scraper shaft 8, the air inlet box 1 is located above the filter bag 3 and communicates with the upper opening of the filter bag 3, and the enclosure plate 2 is mounted on the filter bag 3. The periphery of the filter bag 3 is also provided with an air outlet, the ash hopper 5 is located below the filter bag 3 and communicated with the lower mouth of the filter bag 3, and the dust compactor 6 is located below the ash hopper 5, and the dust is compacted. The compactor 6 is driven by a pressing deceleration motor 7, and the compacting deceleration motor 7 is located on one side of the dust compactor 6. A bracket 12 is provided inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com